Shearing apparatus of metal sheet

A technology of sheet metal and shearing devices, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low automation efficiency, trivial and complex cutting, and low production efficiency, and achieve high automation production efficiency and worker skill requirements The effect of low cost and fewer operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

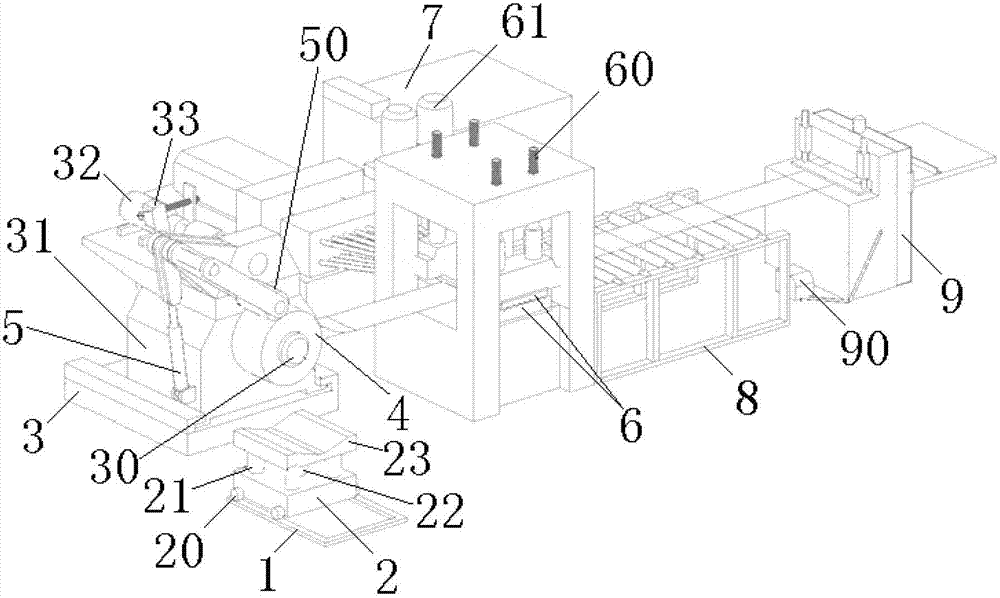

[0019] Such as Figure 1 to Figure 3 As shown, a sheet metal shearing device includes a feeding mechanism, an uncoiling mechanism, a straightening mechanism, a shearing mechanism, a hydraulic power system, and an electrical control system, and can complete uncoiling, straightening, and shearing operations at one time. High automation production efficiency.

[0020] Feeding mechanism comprises feeding car guide rail 1, feeding car base 2, wheel 20, material table 23, and wheel 20 is located at the bottom of feeding car base 2, and material table 23 is located at the top of feeding car base 2, and on material table 23 and the loading car base 2 are provided with a guide rod 21 and a material table lifting cylinder 22 that controls the lifting of the material table. The metal plate 4 feeding ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com