Valve rod extruding assembly fixture for butterfly valve with rubber lining

A technology for assembling fixtures and butterfly valves, applied to assembly machines, manufacturing tools, metal processing equipment, etc., can solve the problems of manual knocking uncertain safety factors, rubber-lined valve seats prone to damage, uneven impact force, etc., to achieve The installation is evenly stressed, not easy to be damaged, and the effect of increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

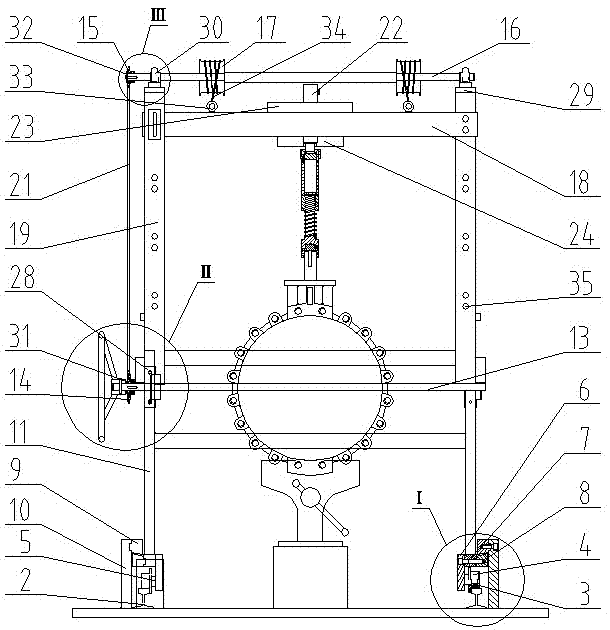

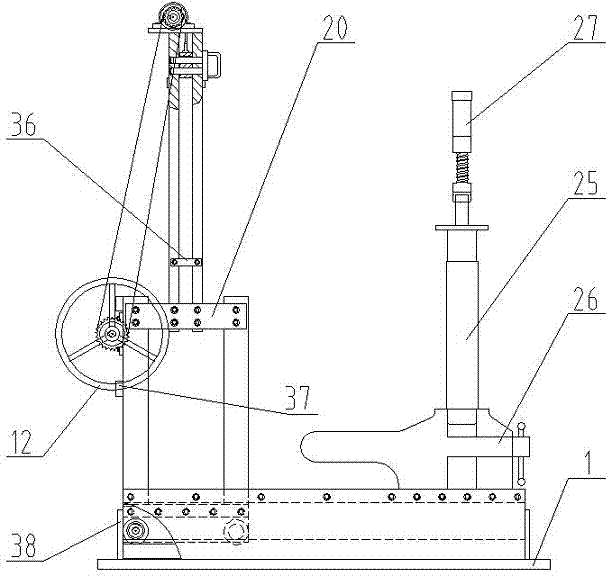

[0028] The present invention will be further described below with reference to the accompanying drawings.

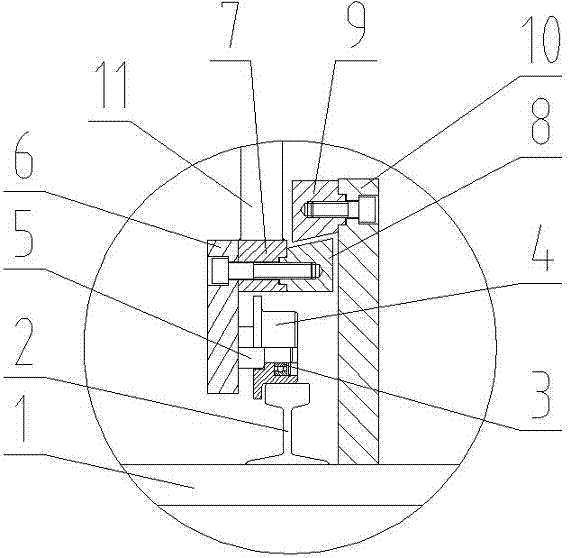

[0029] Such as Figure 1 to Figure 5 As shown, a rubber-lined butterfly valve stem extrusion assembly fixture includes a sliding device and a fixing device for fixing the valve body 25 on one side of the sliding device. The sliding device includes a transmission mechanism and an extrusion mechanism for extruding the valve stem. and a moving mechanism, the extruding mechanism is connected with a transmission mechanism, and the transmission mechanism is arranged above the moving mechanism.

[0030] The moving mechanism includes a base plate 1, a guide rail 2, a ball bearing 3, a roller 4 sliding along the guide rail and a roller shaft 5, the guide rail 2 is fixedly connected to the base plate 1, and the roller 4 is connected to the roller shaft 5 through the ball bearing 3. One side of the roller shaft 5 is provided with a roller fixing plate 6 for fixing the roller 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com