Radial fixed bed oxidative dehydrogenation reactor for regenerating catalyst by sections

A radial fixed bed, oxidative dehydrogenation technology, applied in chemical instruments and methods, organic chemistry, chemical recovery, etc., can solve the problems of affecting the economic benefits of the device, increasing energy consumption, reducing catalyst activity, etc., and prolonging the continuous operation cycle , Reduce production fluctuations and improve operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

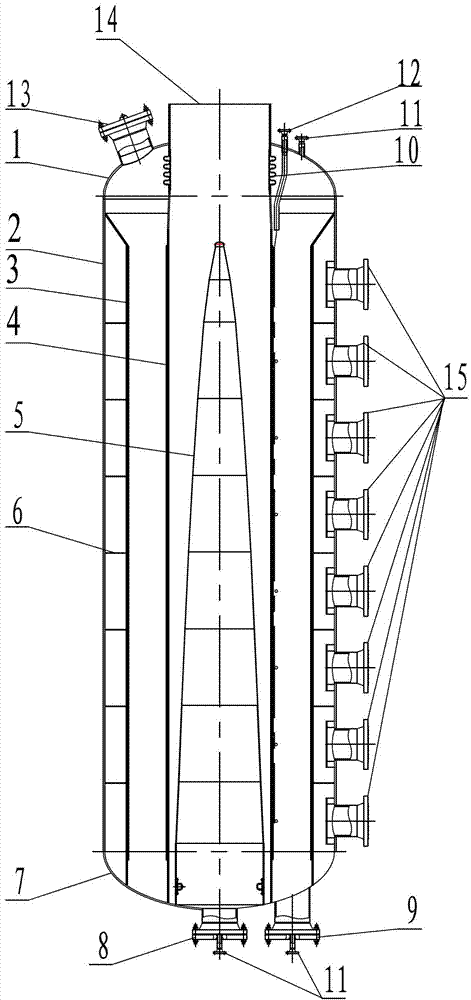

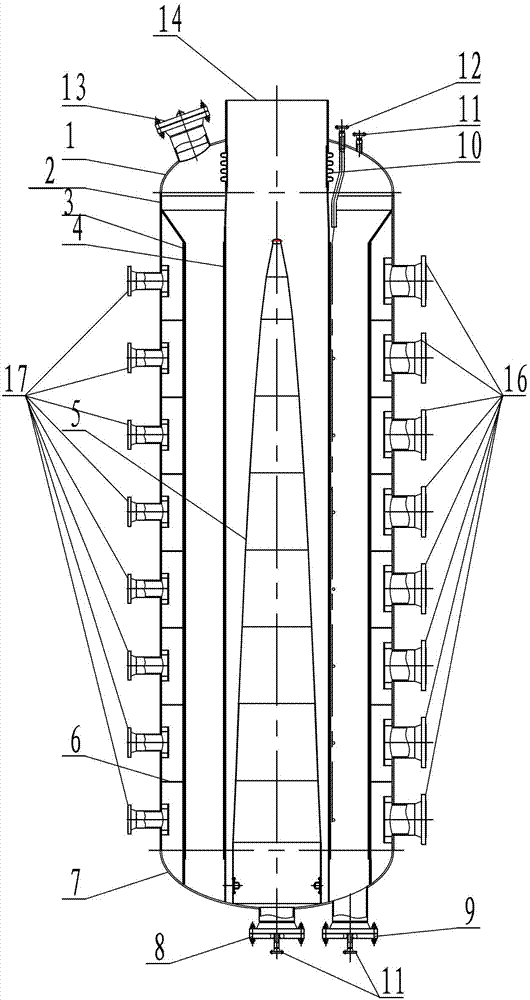

[0026] Such as Figure 1~2 Shown, the present invention comprises: 1# reactor and 2# reactor, the reaction gas outlet 14 of 1# reactor is connected the reaction gas inlet 16 of 2# reactor by pipeline, it is characterized in that described 1# reactor And the 2# reactor is a pressure-bearing shell composed of a cylinder body 2, an upper head 1 and a lower head 7, and a concentric catalyst inner cylinder 4 composed of an open-hole cylinder and a Johnson net is arranged in the pressure-bearing shell. The catalyst outer cylinder 3, the annular space between the catalyst inner cylinder 4 and the catalyst outer cylinder 3 is filled with catalyst, and the part without Johnson mesh is filled with inert magnetic balls. A distribution cone 5 is arranged in the catalyst inner cylinder 4, and seven ring plates 6 are arranged between the catalyst outer cylinder 3 and the cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com