Hexahedral flexible rotating mechanism

A technology of rotating mechanism and hexahedron, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high maintenance cost, increased cost, high cost, etc., and achieve simple rotating structure, stable switching, and many types Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

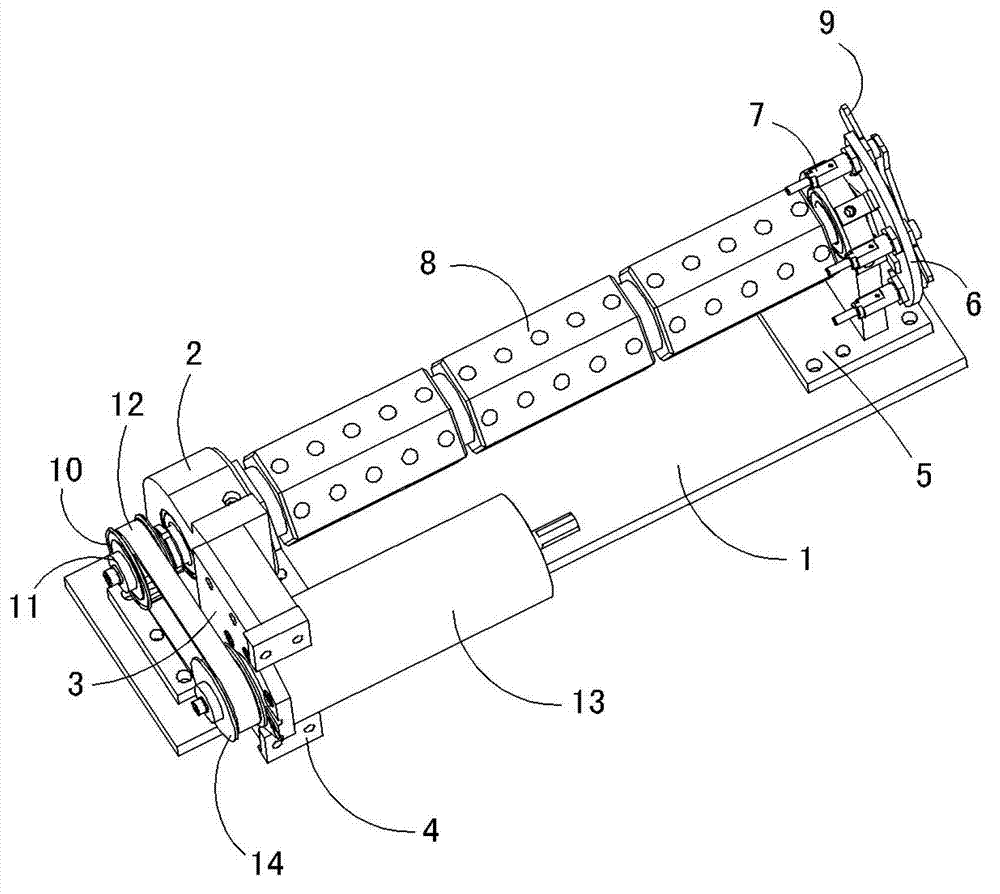

[0013] see figure 1 , the structure of the hexahedral rotating mechanism in this embodiment is set as:

[0014] The two ends of base plate 1 are respectively fixedly provided with the fixed base that front support 2 and rear support 5 constitute; The hexahedral rotating shaft 8 that is driven by synchronous pulley 10 is supported on front support 2 and rear support 5 by bearing; Set driving motor 13. A synchronous belt 12 is set between the output wheel 14 of the drive motor 13 and the synchronous pulley 10 to form a belt transmission mechanism, and multiple planes of the hexahedral shaft 8 are respectively positioned on the working position to form multiple different working surfaces.

[0015] In specific implementation, such as figure 1 As shown, the driving motor 13 is fixedly arranged on the base plate 1 by the motor fixing plate 3 and the baffle plate 4, and the end face of the synchronous pulley 10 is provided with a synchronous pulley baffle 11;

[0016] An induction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com