Method for producing acid through promoting anaerobic fermentation of residual sludge by virtue of rhamnolipid biosurfactant

A rhamnolipid, excess sludge technology, applied in microorganism-based methods, biochemical equipment and methods, fermentation and other directions, can solve the secondary pollution of excess sludge, weak acidification of excess sludge, chemical surfactants There are problems such as toxicity, to achieve the effect of eliminating secondary pollution, good biodegradability and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

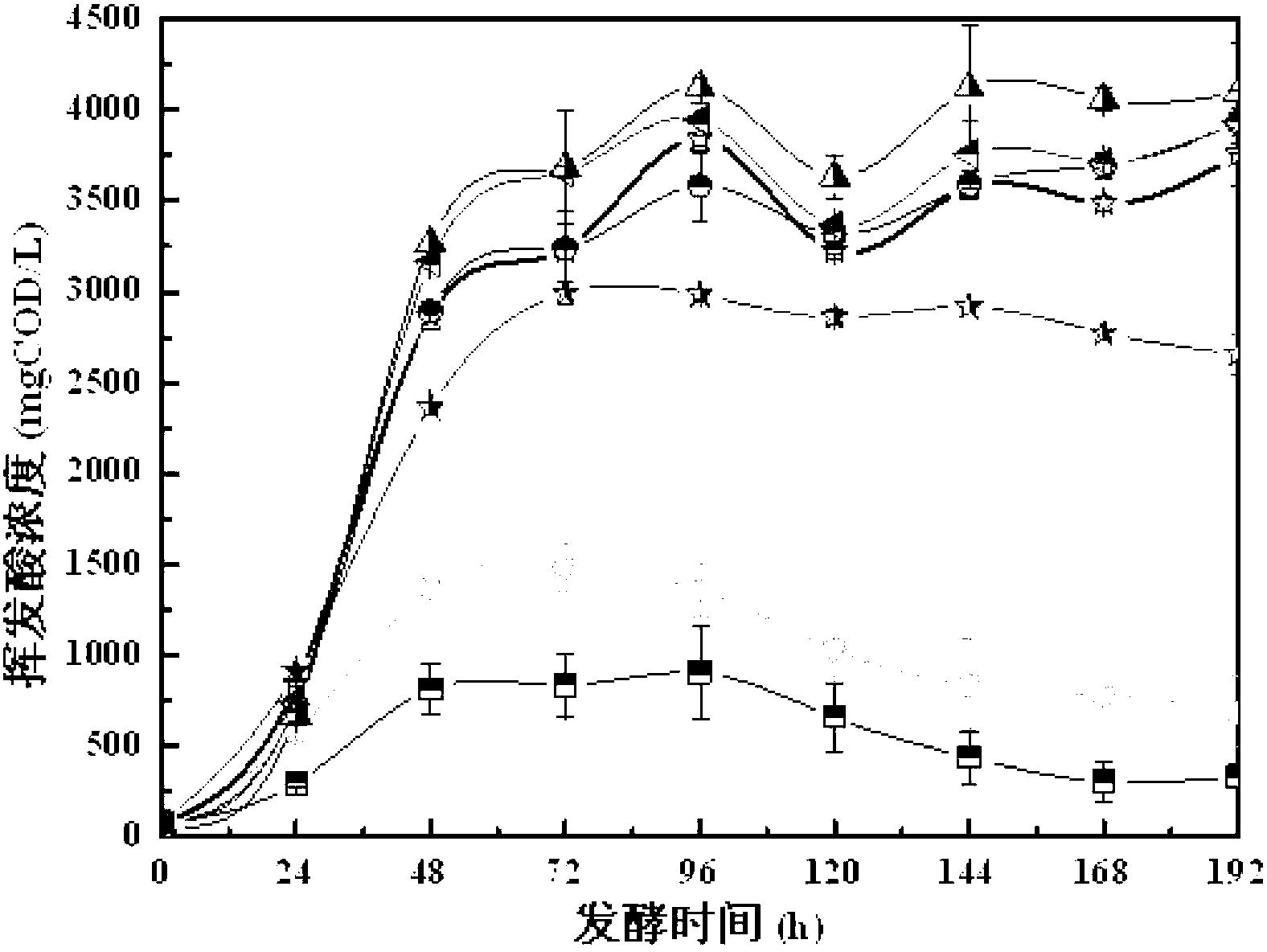

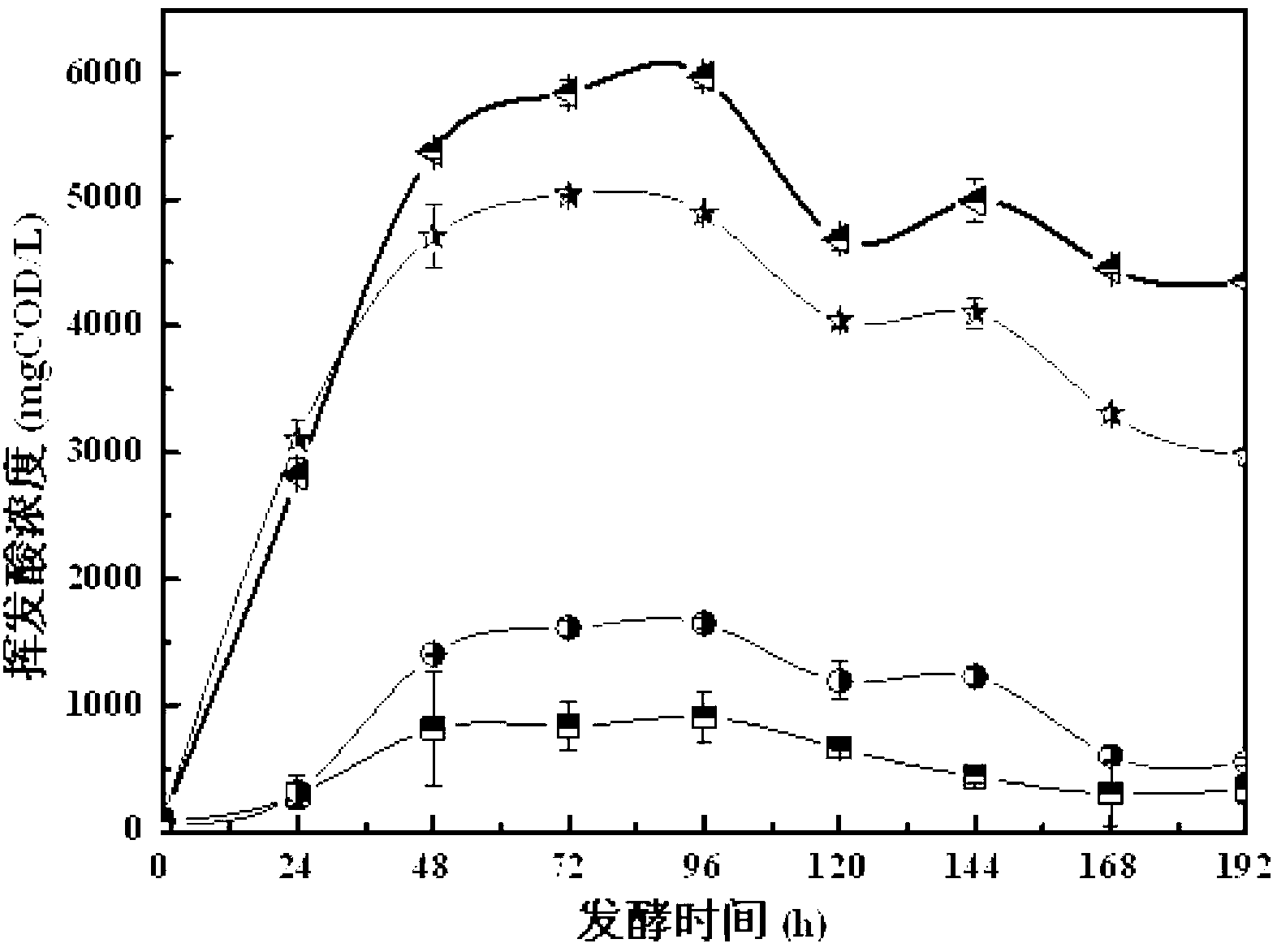

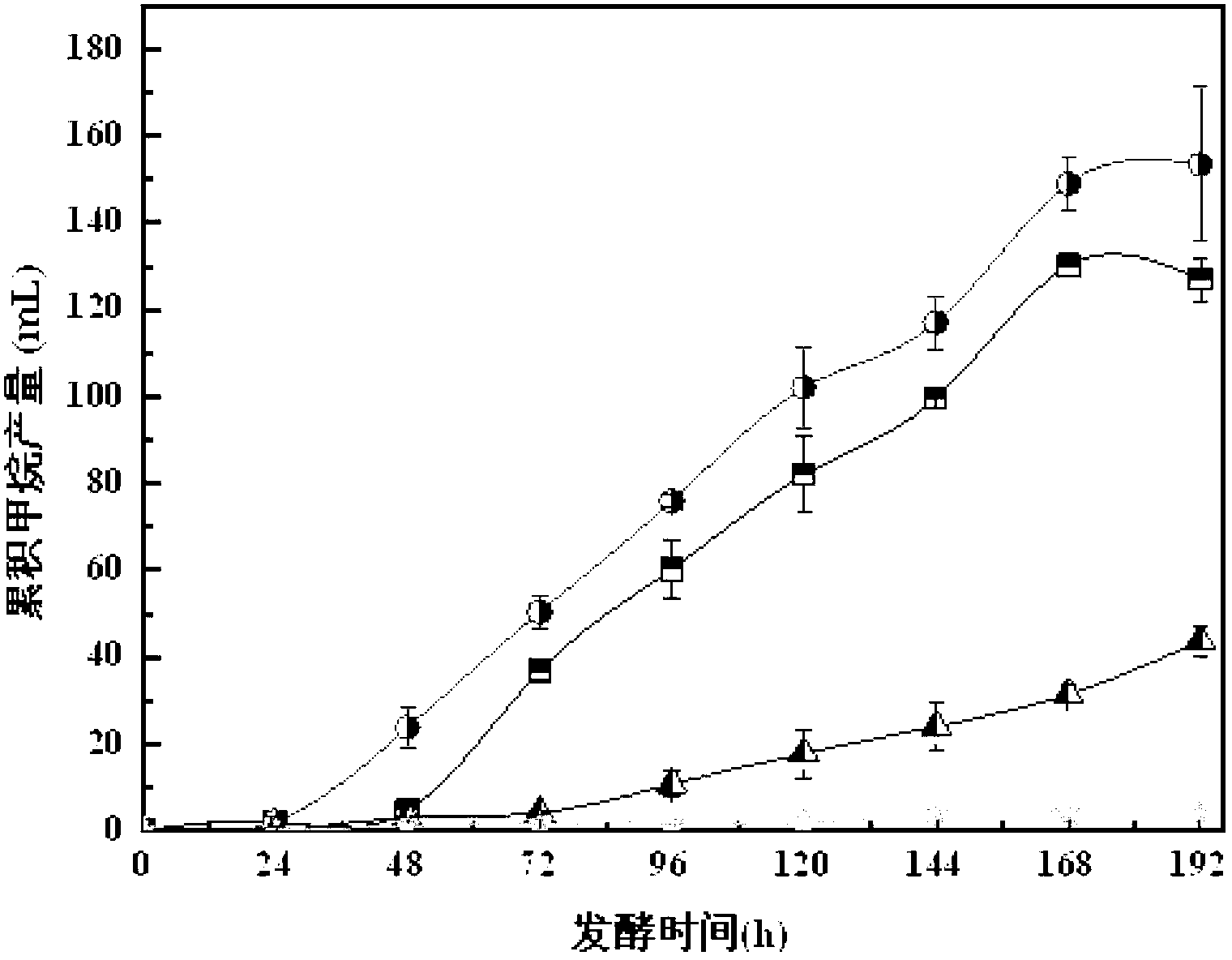

[0015] Specific embodiment one: the method that the rhamnolipid biosurfactant of the present embodiment promotes the anaerobic fermentation of excess sludge to produce acid is specifically carried out according to the following steps:

[0016] 1. Put the remaining sludge into a container for natural settlement at a temperature of 4°C for 24-30 hours, then drain the supernatant to obtain a sludge sample;

[0017] 2. Put the sludge sample into the reaction bottle, add rhamnolipid, and the dosage of rhamnolipid is 0.005~0.10g / gVSS;

[0018] 3. After deoxygenating and filling the reaction bottle with nitrogen for 10 minutes, seal the reaction bottle and place it in an air bath shaker at a speed of 100-110rpm / min for anaerobic fermentation. The fermentation temperature is 35-38°C and the fermentation time is 96-192h. , to complete the process in which the rhamnolipid biosurfactant promotes the anaerobic fermentation of excess sludge to produce acid.

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the residual sludge in step 1 contains Clostridium spp. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment differs from Embodiment 1 to Embodiment 2 in that: the settling time in step 1 is 25-29 hours. Others are the same as one of the specific embodiments 1 to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com