Roller and roller core shaft group for glass base plate carrying

A technology of glass substrates and rollers, which is applied in the direction of furnace components, conveyor objects, furnaces, etc., can solve the problems affecting the replacement of elastic rims, insufficient dimensional accuracy of rollers, and affecting production progress, so as to reduce maintenance costs, shorten time, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

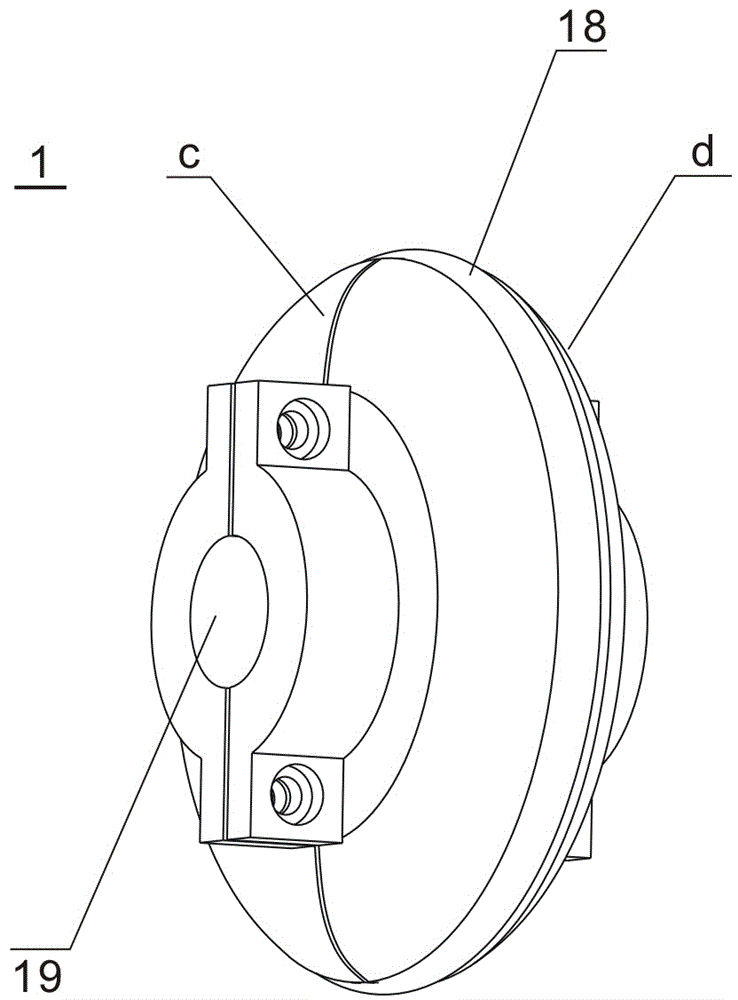

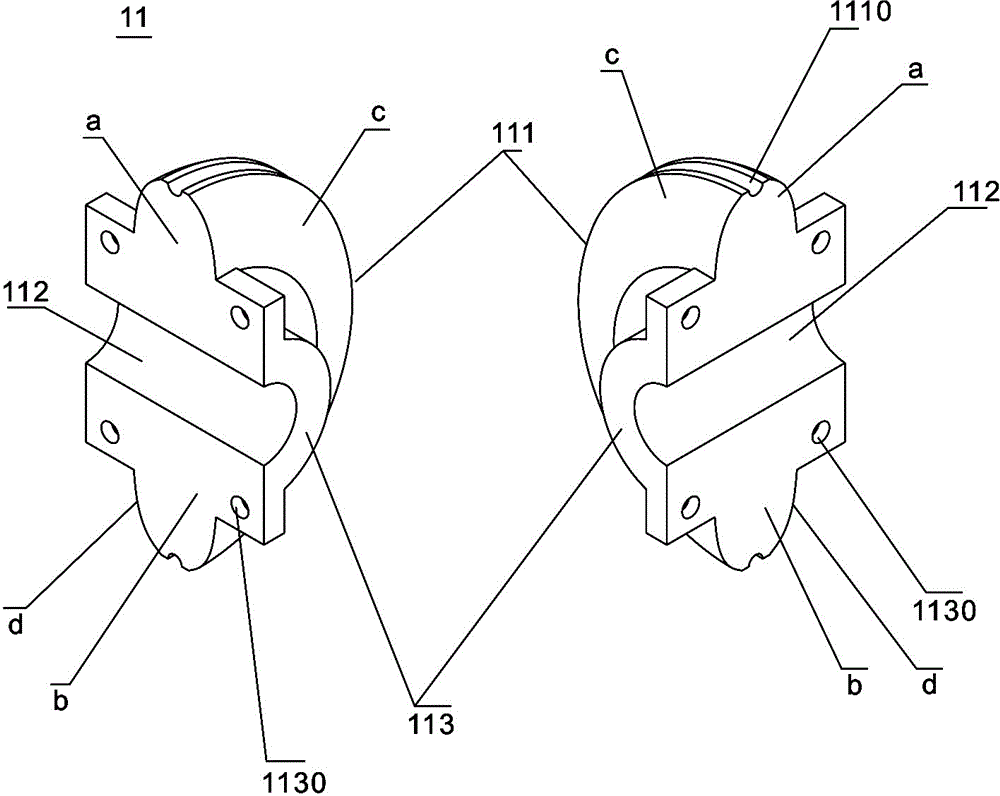

[0053] The detachable roller structure of the roller mandrel assembly of the present invention may adopt one or more of the above-mentioned embodiments of the rollers used for carrying glass substrates, and details will not be repeated here.

[0054] The roller and the roller mandrel assembly for carrying glass substrates according to the present invention can be detachably locked on the roller mandrel because the roller is a wheel body structure assembled from a plurality of roller assemblies. When local rollers are worn out, there is no need to disassemble and reinstall the entire roller mandrel group, just remove and replace the worn single roller; further shorten the time for replacing the glass substrate rollers, improve the utilization rate of the rollers, and reduce the maintenance cost of the equipment; Elastic software is provided on the rollers, which can avoid scratches on the surface of the glass substrate due to insufficient dimensional accuracy of the rollers or r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com