Liquid container and liquid ejecting apparatus including liquid container

A technology of liquid container and spraying device, which is applied in printing and other directions, and can solve the problems of no improvement in sensitivity and decrease in sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Hereinafter, in order to clarify the contents of the present invention described above, examples will be described in the following order.

[0060] A. The structure of inkjet printer:

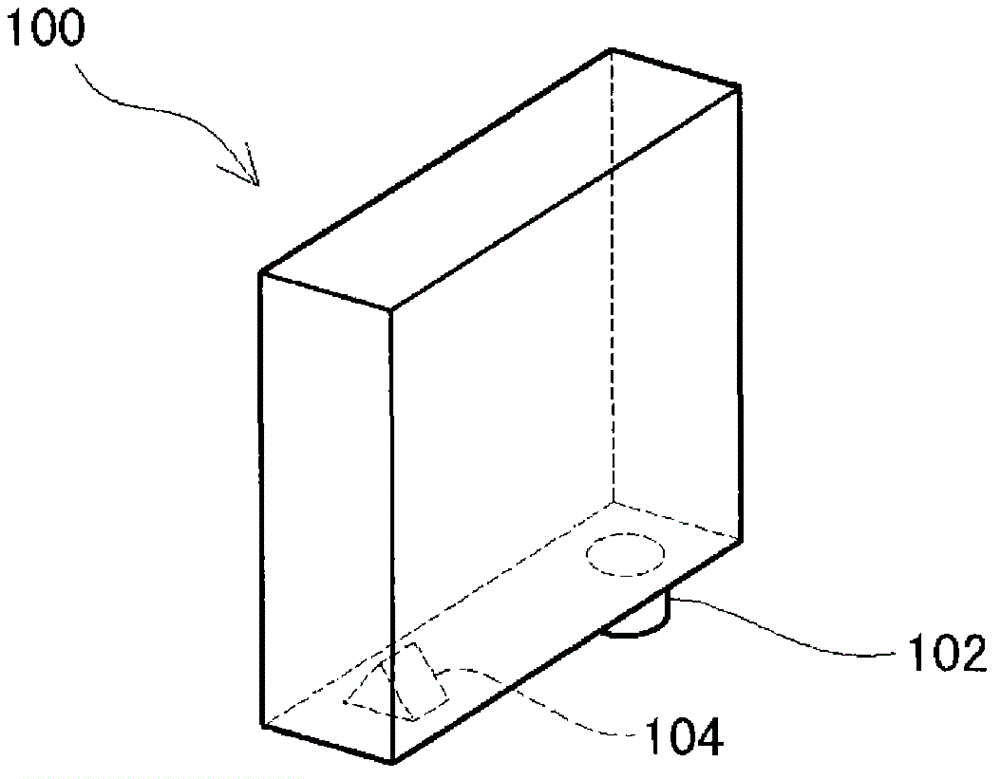

[0061] B. Construction of the ink cartridge:

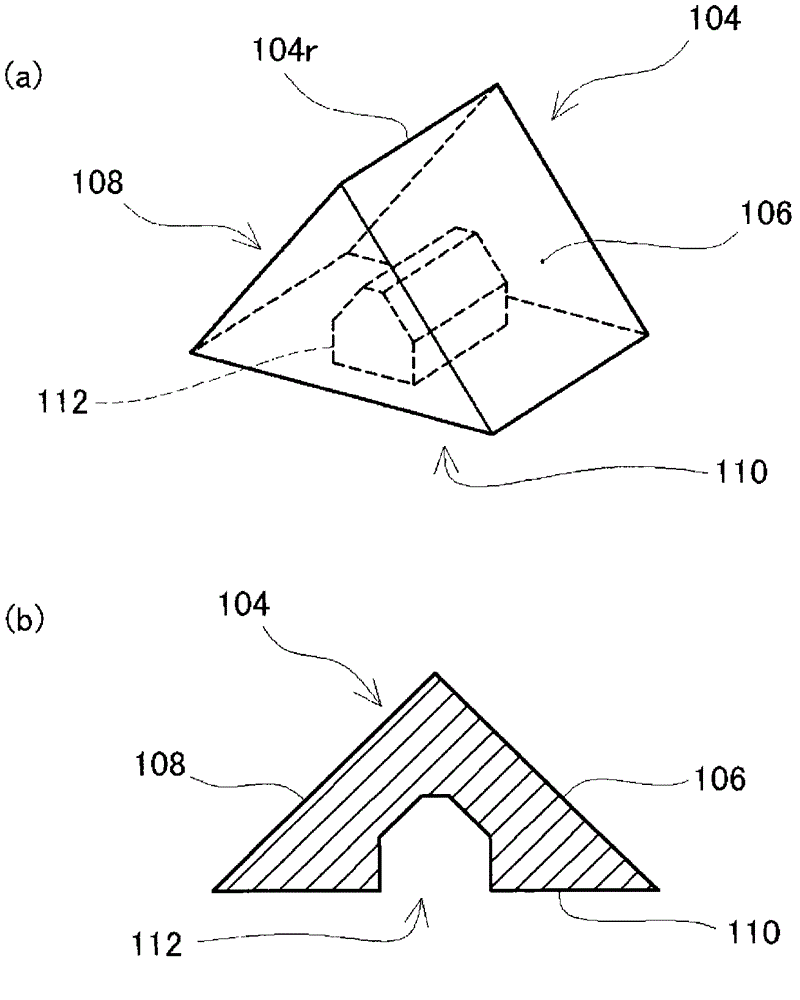

[0062] C. Ink detection method:

[0063] D. Variations:

[0064] D—1. The first modified example:

[0065] D-2. The second modified example:

[0066] A. The structure of inkjet printer:

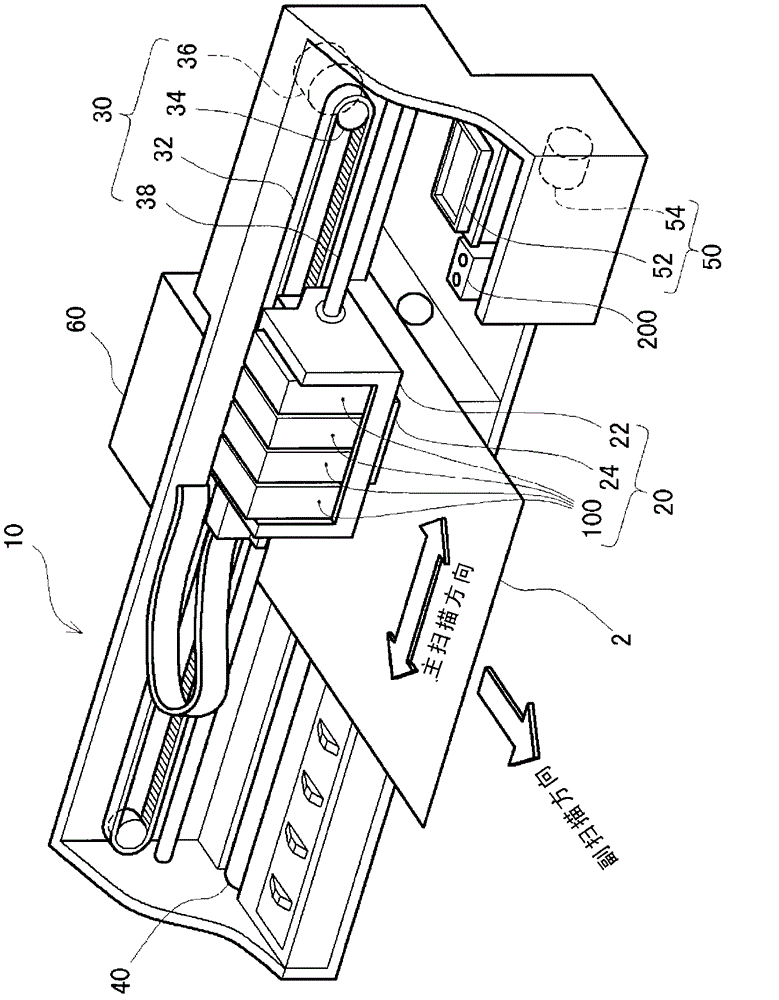

[0067] figure 1 This is an explanatory diagram illustrating a schematic configuration of a liquid ejecting device, as an example of an inkjet printer equipped with an ink cartridge. As shown in the figure, the inkjet printer 10 includes: a carriage 20 that forms ink dots on printing paper 2 as a printing medium while reciprocating in the main scanning direction; a drive mechanism 30 that reciprocates the carriage 20; The press roller 40 for feeding the printing paper 2; and the maintenance mechanism 50 for maintaining normal printing. The carriage 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com