High-strength corrugated composite paperboard production equipment

A production equipment, cardboard technology, applied in the direction of mechanical processing/deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

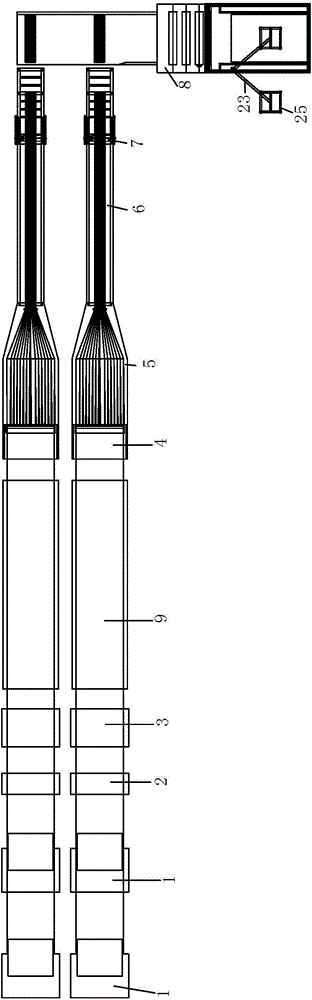

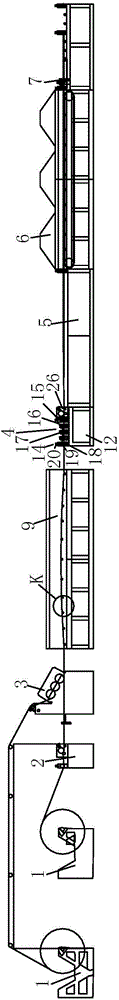

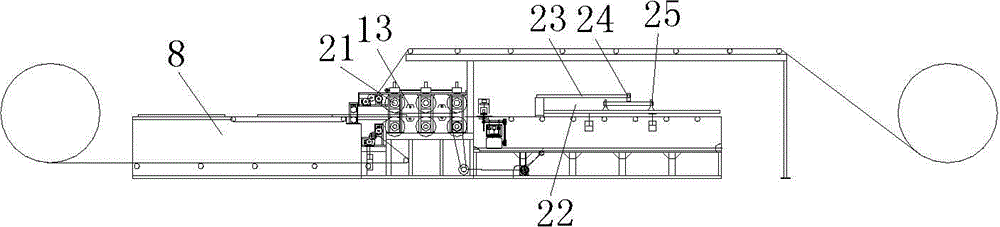

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] The production process of the high-strength corrugated composite cardboard involved in the present invention is carried out according to the following process steps:

[0023] 1) To make corrugated cardboard, fold the upper paper into corrugated paper, apply glue on the upper plane of the lower paper, and glue the corrugated paper on the upper plane of the lower paper;

[0024] 2) Drying, put the product produced in step 1) into a drying box for drying to form a three-layer composite corrugated cardboard with corrugated, glued film and plane;

[0025] 3) Slitting and gluing, cut the dried corrugated cardboard into strips according to the requirements, and apply glue on the wavy peaks of the strips of corrugated cardboard;

[0026] 4) Side-standing compounding, a number of strip-shaped corrugated cardboards cut into strips are placed sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com