Vehicle speed sensor mounting structure

A vehicle speed sensor and structure technology, which is applied in the field of vehicle speed sensor installation and structure, can solve the problems of vehicle speed sensor disassembly or maintenance difficulties, and achieve the effects of improving the readiness, reducing the quantity, and improving the readiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

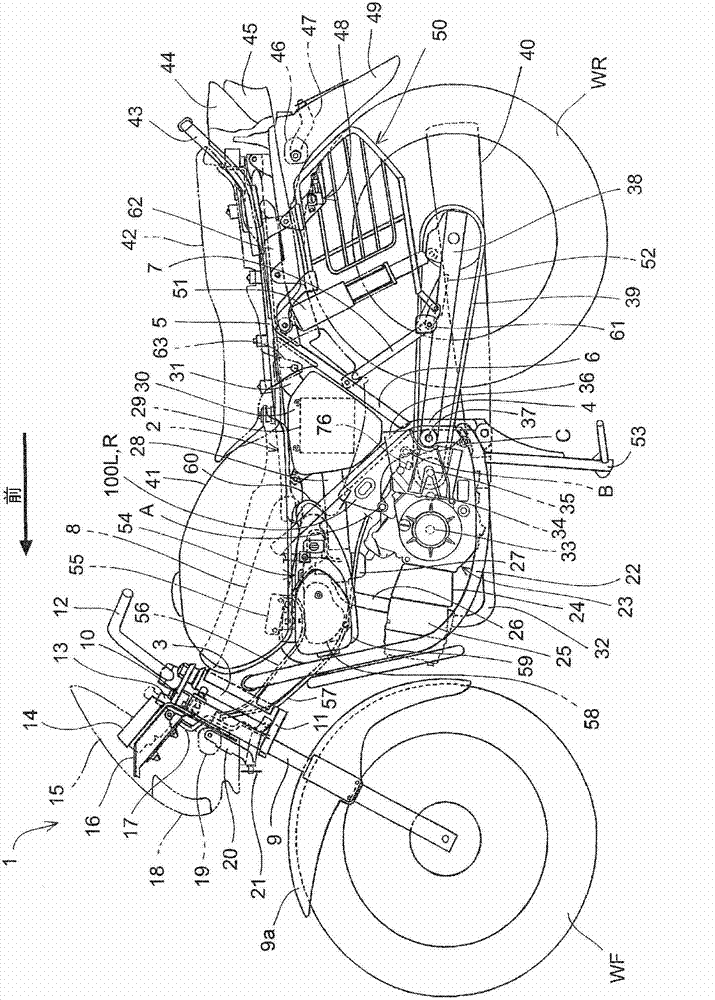

[0042] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a side view of the motorcycle 1 to which the vehicle speed sensor mounting structure of the present invention is applied. The frame 2 of the motorcycle 1 includes: a head pipe 3 at the front end of the vehicle body; a main frame 8 extending rearward from the head pipe 3; a pair of left and right seat rails connected to the rear end of the main frame 8 and extending rearward. 5; a pair of left and right down frames 22 connected to the front end of the main frame 8 and extending downward; a pair of left and right central frames extending downward from the rear of the main frame 8 and connected to the rear end of the down frame 22 4; and a pair of left and right subframes 6 connecting the seat rail 5 and the center frame 4 . A center ladder 53 is rotatably attached to the lower end of the center frame 4 .

[0043] A front fork 9 is attach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com