Resin composition for sealing semiconductors, and semiconductor device using same

A resin composition and semiconductor technology, which can be applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, and semiconductor/solid-state device parts, etc., and can solve the problems of insufficient balance of continuous formability, adhesion resistance, flame resistance and welding resistance. , to achieve the effect of excellent reliability and excellent solder resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0179] The following components were mixed at normal temperature with a mixer, melted and kneaded with a heating roll at 80° C. to 100° C., cooled, and then pulverized to obtain a resin composition.

[0180] Epoxy resin 1 8.83 parts by mass,

[0181] 1 3.67 parts by mass of phenolic resin curing agent,

[0182] Inorganic filler 186.5 parts by mass,

[0183] Curing accelerator 1 0.4 parts by mass,

[0184] Silane coupling agent 1 0.1 parts by mass,

[0185] Silane coupling agent 2 0.05 parts by mass,

[0186] Silane coupling agent 3 0.05 parts by mass,

[0187] 0.3 parts by mass of carbon black,

[0188] 0.1 part by mass of carnauba wax,

[0189] The following items were evaluated about the obtained resin composition. Table 1 shows the evaluation results.

[0190] evaluation item

[0191] Spiral flow: Using a low-pressure transfer molding machine (manufactured by Kohtaki Precision Machine Co., Ltd., KTS-15), under the conditions of 175°C, injection pressure 6.9MPa, and...

Embodiment 2~12

[0199] Embodiment 2~12, comparative example 1~4

[0200] Based on the composition of Table 2, Table 3, and Table 4, it carried out similarly to Example 1, the resin composition for semiconductor sealing was manufactured, and it evaluated similarly to Example 1. The evaluation results are shown in 2, 3 and Table.

[0201] Table 2

[0202]

[0203] table 3

[0204]

[0205] Table 4

[0206]

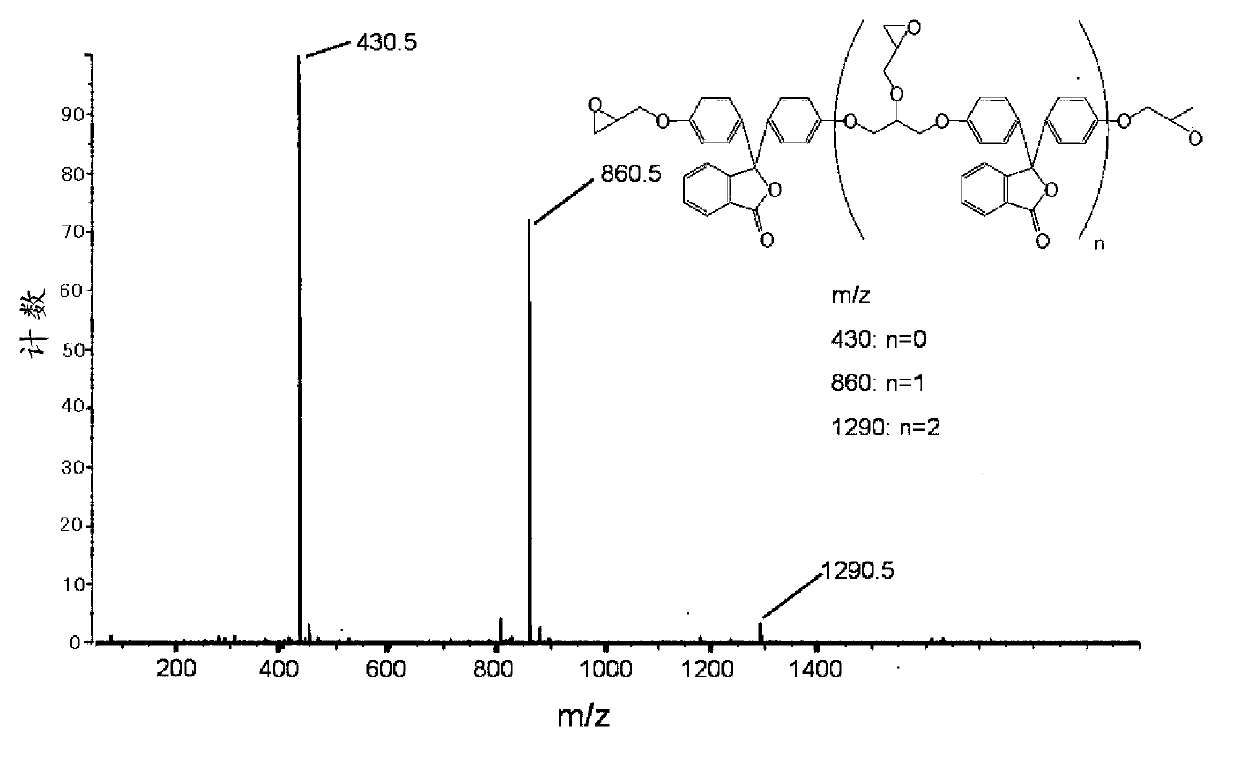

[0207] Examples 1 to 12 are resin compositions containing epoxy resin (A-1) represented by formula (1), phenolic resin curing agent (B) and inorganic filler (C), including changing the epoxy resin (A-1 - Resin composition with molecular weight distribution of 1), resin composition in which type of phenolic resin (B) was changed, resin composition in which two types of phenolic resin (B) were used in combination, type of curing accelerator (D) was changed Excellent balance of fluidity (spiral flow), continuous moldability, sticking resistance, flame resistance, soldering resista...

Embodiment 13)

[0227] The following components were mixed at normal temperature with a mixer, melted and kneaded under a heating roll at 80° C. to 100° C., cooled, and then pulverized to obtain a resin composition for encapsulating a semiconductor.

[0228]

[0229]

[0230] The obtained resin composition for encapsulating a semiconductor was evaluated for spiral flow, flame resistance, water absorption, continuous moldability, solder resistance, and high-temperature storage characteristics. The evaluation methods of spiral flow, flame resistance, continuous moldability, solder resistance, and high-temperature storage characteristics are as described above. The evaluation results are shown in Table 5.

[0231] Boiling water absorption: Using a low-pressure transfer molding machine (manufactured by Kohtaki Precision Machine Co., Ltd., KTS-30), a disc-shaped test piece with a diameter of 50mm and a thickness of 3mm was tested at a mold temperature of 175°C, an injection pressure of 9.8MP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com