Optical-fiber coupled output end surface pumped solid-state laser and manufacture technology

A solid-state laser and fiber coupling technology, which is applied in the direction of lasers, laser components, phonon exciters, etc., can solve problems such as difficult adjustment of coupling, reduction of coupling efficiency, and limitation of flexible coupling connections of lasers, so as to improve beam quality and simplify Output coupling structure, effect of suppressing oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

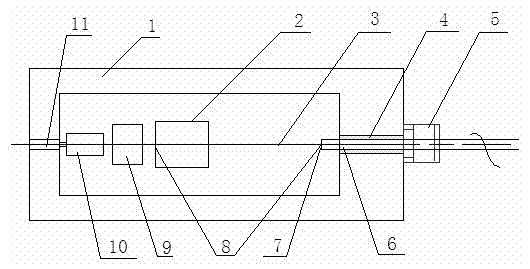

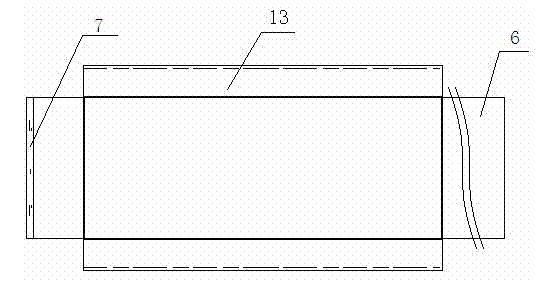

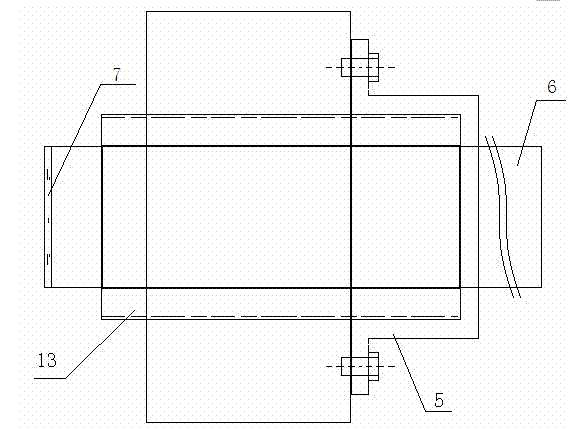

[0041] Such as figure 1 As shown, a fiber-coupled output end-pumped solid-state laser includes a laser medium 2 and an output optical fiber 6 fixed in a housing 1. The left end of the laser medium 2 is coated with a 1064nm full-reflection film and an 808nm full-transmission film. The surface is coated with 1064nm antireflection film and 808nm total reflection film; the end face of output fiber 6 in housing 1 is coated with 1064nm partial transmission film and 808nm total reflection film, and the end face of laser medium 2 is coated with 1064nm total reflection film and output fiber 6 is coated with The end face of the 1064nm partial transmission film forms a resonant cavity 8 in the housing 1, the end face laser diode 10 and the coupling lens 9 are fixed on the left end of the laser medium 2 from left to right, and the end face laser diode 10 acts on the laser medium 2 through the coupling lens 9 Above, the laser medium 2 is pumped outside the cavity by the end-face laser diod...

Embodiment 2

[0047] Such as Figure 4 As shown, the difference between embodiment 2 and embodiment 1 is that a Q-switched crystal 12 is added between the laser medium 2 and the inner end face of the output fiber 6 to form a laser diode-pumped Q-switched solid-state laser.

Embodiment 3

[0049] Such as Figure 5 As shown, the difference between Embodiment 3 and Embodiment 2 lies in that: not only a Q-switched crystal 12 is added between the laser medium 2 and the inner end face of the output fiber 6 to form a laser diode-pumped Q-switched solid-state laser. At the same time, a pumping side laser diode 14 is added on the side of the laser medium 2, and the pumping side laser diode 14 and the pumping end face laser diode 10 jointly pump the laser medium 2 to increase the output power.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com