Vertical transportation device

A vertical transportation and winding device technology, which is applied in the direction of construction, building structure, and building materials processing, can solve the problems of vertical transportation such as long-term queuing, large drifting range, and busy tower cranes, and achieves stable vertical transportation. The effect of reducing queuing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

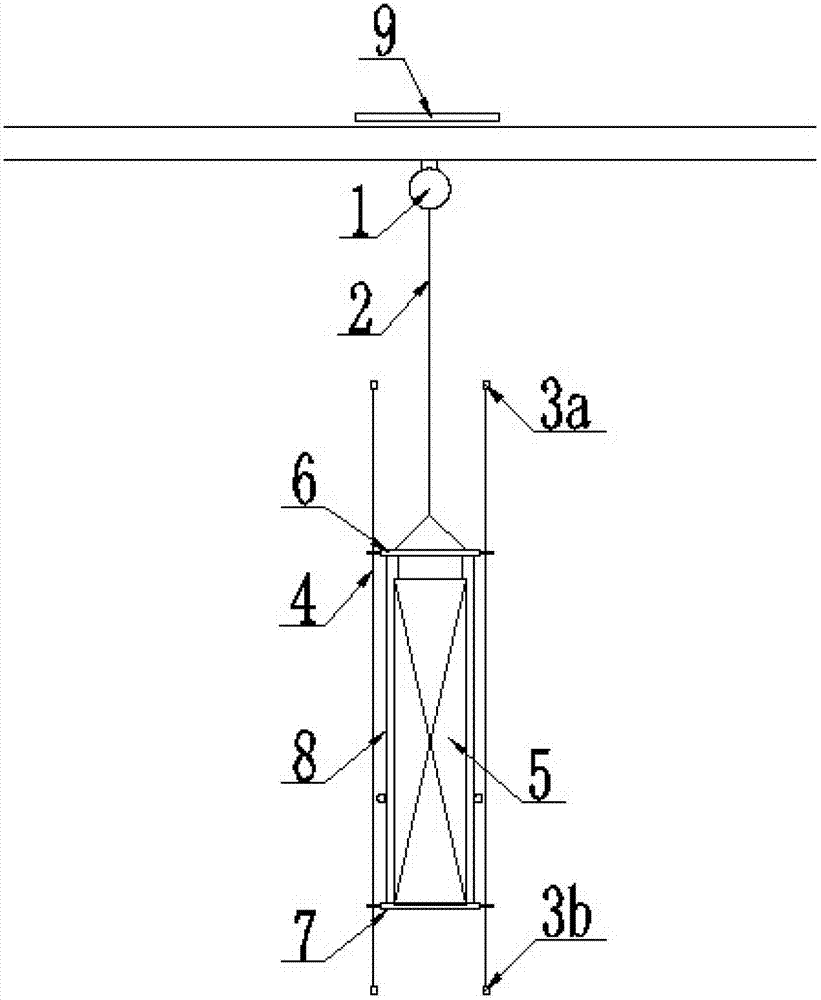

[0012] as attached figure 1 Shown is a vertical transport device of the present invention, power winding device 1, hoisting rope 2, upper guide cable corbel 3a, lower guide cable corbel 3b, guide cable 4, hanging basket 5, anti-fall baffle 9; The power winding device 1 is installed on the top of the vertical transport station; a part of the hoisting rope 2 is bound in the power winding device 1, and the other part hangs below the power winding device 1; the upper guide rope bracket 3a has Two, and installed on the top of the vertical transport station, located on both sides of the hoisting rope 2, the distance between the two upper guide rope corbels 3a and the hoisting rope 2 is equal, and the distance between the two upper guide rope corbels 3a is the same as The width of the hanging basket 5 is consistent; the lower guide cable brackets 3b have two, and are installed on the bottom of the vertical transport station, correspondingly installed in the same vertical direction as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com