Method for preparing graphene crosslinked type organic aerogel and carbon aerogel by normal-pressure drying

A carbon aerogel, graphene technology, applied in carbon preparation/purification, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as high drying shrinkage rate, and achieve simplified operation process, not easy to shrink, simple and fast The effect of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

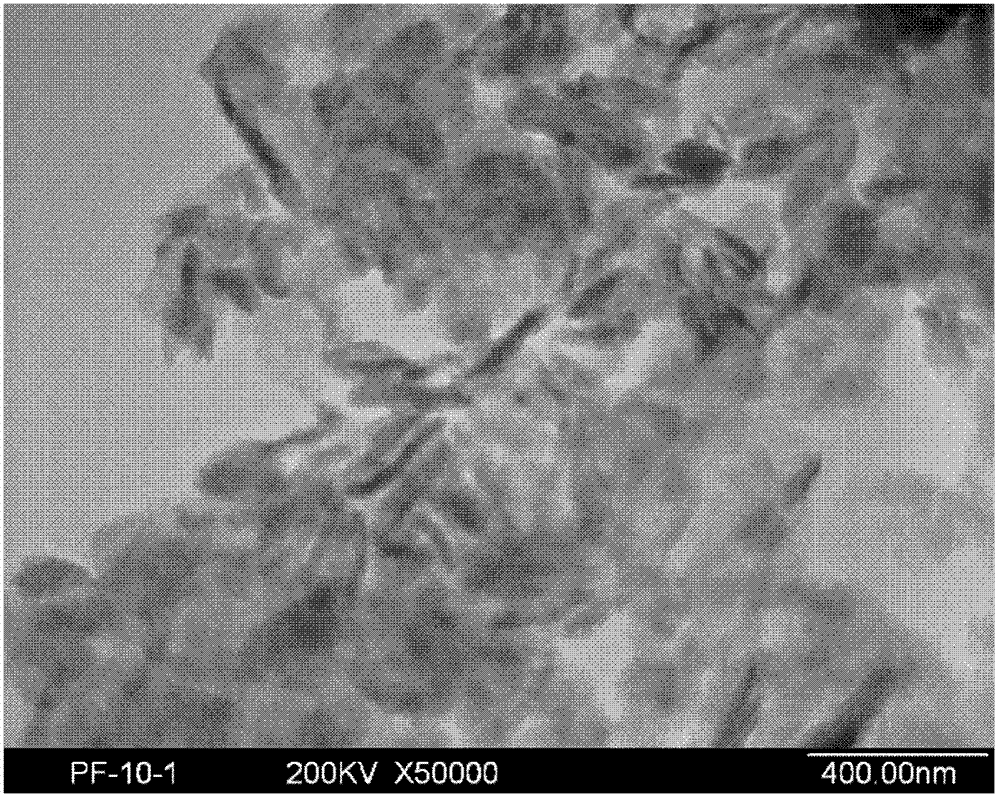

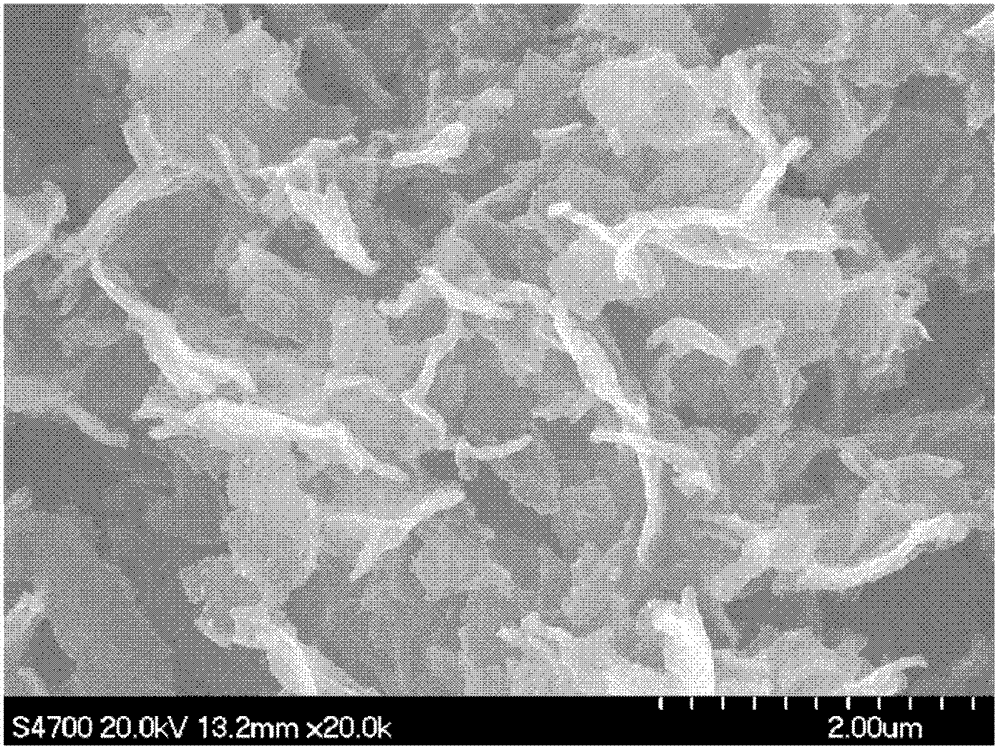

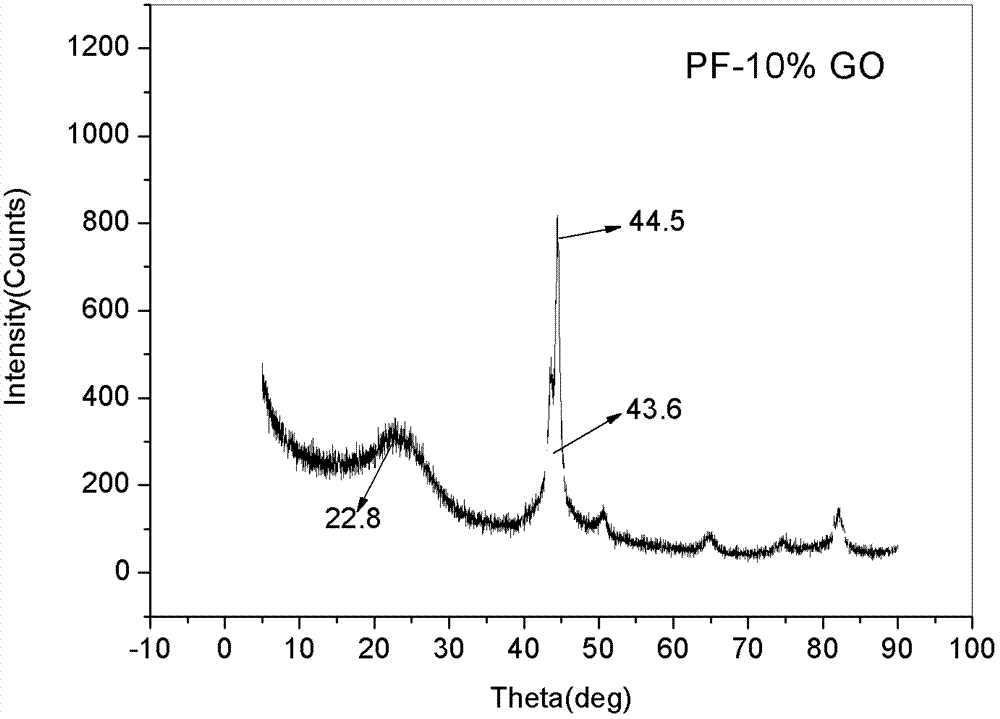

Embodiment 1

[0019] Embodiment 1: Using phenol (P), formaldehyde (F) as reaction monomer, sodium hydroxide as catalyst (C), water as solvent, according to the ratio of P / F=0.33, P / C=20, dubbed solid A solution with a content of 30wt% was added with 2wt% graphene oxide as a crosslinking agent, mixed evenly, heated at 60°C for 60 minutes to obtain a graphene crosslinked organic hydrogel, and aged in a water bath at 85°C for 72h. Then the gel column was taken out and dried at 60° C. under normal pressure for 24 hours to form an organic aerogel. Put the organic airgel into a carbonization furnace, pass through the nitrogen protection, and carry out carbonization at a constant temperature of 900 ° C for 2 hours, and finally form a carbon aerogel. The specific surface area of carbon airgel is 485m 2 / g, pore volume 0.72cm 3 / g, the carbonization shrinkage rate is 49.9%.

Embodiment 2

[0020] Embodiment 2: Using resorcinol (R) and formaldehyde (F) as the reaction monomer, sodium carbonate as the catalyst, and water as the solvent, according to the ratio of R / F=0.5, R / C=200, the solid content is formulated To a 5wt% solution, add 20wt% functionalized graphene oxide as a crosslinking agent and mix evenly, obtain a graphene crosslinked organic hydrogel at 20°C for 5 minutes, and put it in a 75°C water bath for aging for 7 days. Then the hydrogel column was taken out and dried under infrared light for 10 h to form an organic aerogel. Put the organic airgel into a carbonization furnace, pass through the nitrogen protection, and carry out carbonization at a constant temperature of 800 ° C for 1 hour, and finally form a carbon aerogel. The specific surface area of carbon airgel is 382m 2 / g, pore volume 0.42cm 3 / g, the carbonization shrinkage rate is 61.9%.

Embodiment 3

[0021] Embodiment 3: Using resorcinol (R) and formaldehyde (F) as the reaction monomer, sodium carbonate as the catalyst, and ethanol as the solvent, according to the ratio of R / F=0.5, R / C=200, the solid content is formulated To a 40wt% solution, add 0.5wt% graphene oxide as a crosslinking agent and mix evenly, heat at 80°C for 180 minutes to obtain a graphene crosslinked organic hydrogel, and put it in an 80°C water bath for aging for 72h. Then the gel column was taken out and dried at room temperature under normal pressure for 48 hours, and then dried at 120° C. for 5 hours to form an organic airgel. Put the organic airgel into a carbonization furnace, pass through nitrogen protection, and carry out carbonization at a constant temperature of 1100 ° C for 2 hours, and finally form carbon aerogel. The specific surface area of carbon airgel is 732m 2 / g, pore volume 1.03cm 3 / g, the average pore diameter is 5.2nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com