Welding clamp of lithium ion battery breaker

A technology of lithium-ion batteries and welding fixtures, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unguaranteed welding consistency, unfavorable production efficiency, low welding efficiency, etc. Industrial application, ensuring welding consistency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

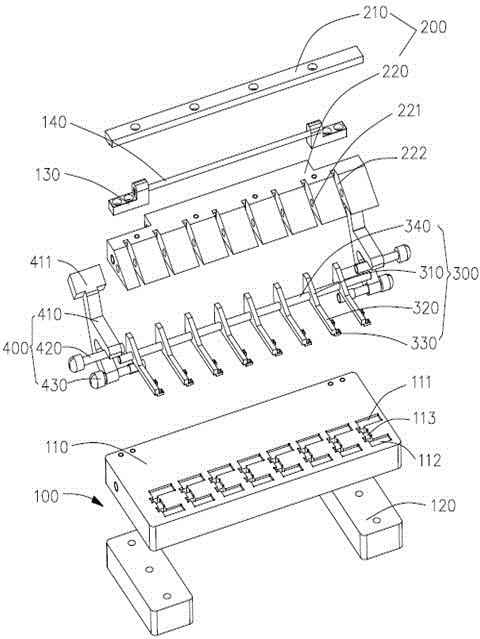

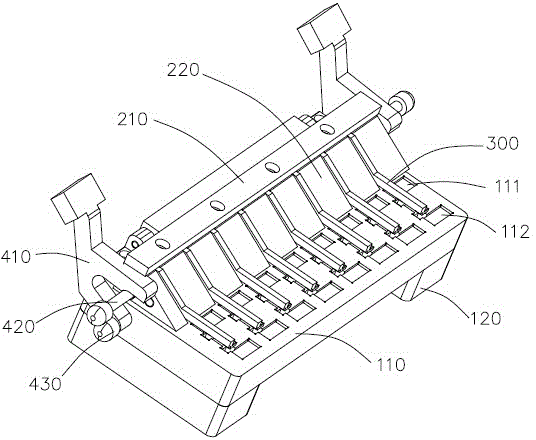

[0023] A welding fixture for a lithium-ion battery circuit breaker, comprising a base 100 and a cover 200, the cover 200 is arranged on the base 100, the cover 200 and the base 100 are movably connected, and the cover 200 can be placed on the base 100 Flip up.

[0024] The base 100 includes a bottom plate 110 and a support seat 120 disposed under the bottom plate 110 , and a plurality of accommodating grooves are opened on the bottom plate 110 , and the accommodating grooves are U-shaped. The accommodating groove includes a first accommodating groove 111, a second accommod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com