Construction method for cast-in-place concrete pile of soft soil foundation with stone layer

A technology of soft soil foundation and construction method, which is applied in basic structure engineering, sheet pile wall, building, etc., can solve the problems of increased concrete consumption, inability to pass through the block stone layer, and increased filling coefficient, so as to achieve simple installation and save manpower. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

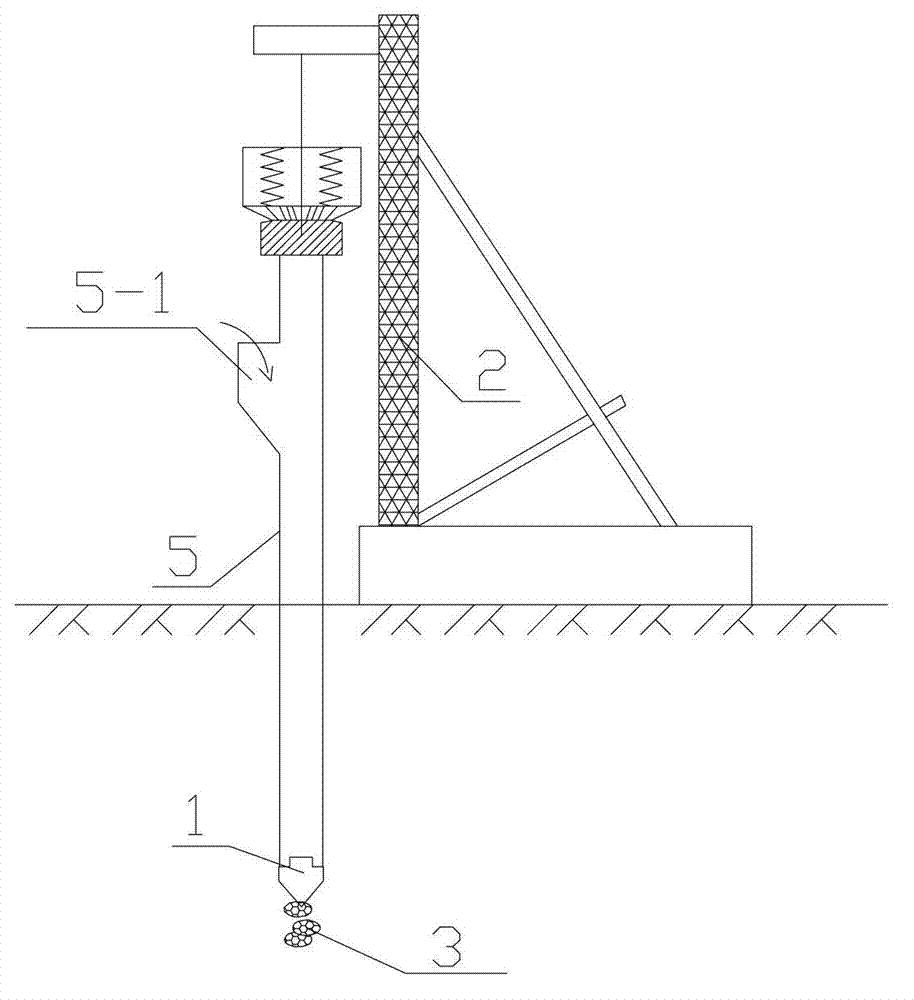

[0020] see Figure 1 to Figure 6 , a kind of soft soil foundation concrete filling pile construction method with block stone layer, comprises the following steps:

[0021] 1) Determining the center position of the reinforced concrete cast-in-place pile 7;

[0022] 2) Sink the prefabricated pile tip 1 to the design position with the steel casing 5 by using the vibration sinking method, and make the bottom elevation of the steel casing 5 equal to the pile bottom elevation;

[0023] In this embodiment, a concrete pouring port 5-1 is provided on one side of the upper end of the steel casing 5. A walking-type vibrating tube sinking pile machine 2 is used, equipped with a DZ110kw vibratory hammer, and the steel casing 5 is pressed on the pile tip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com