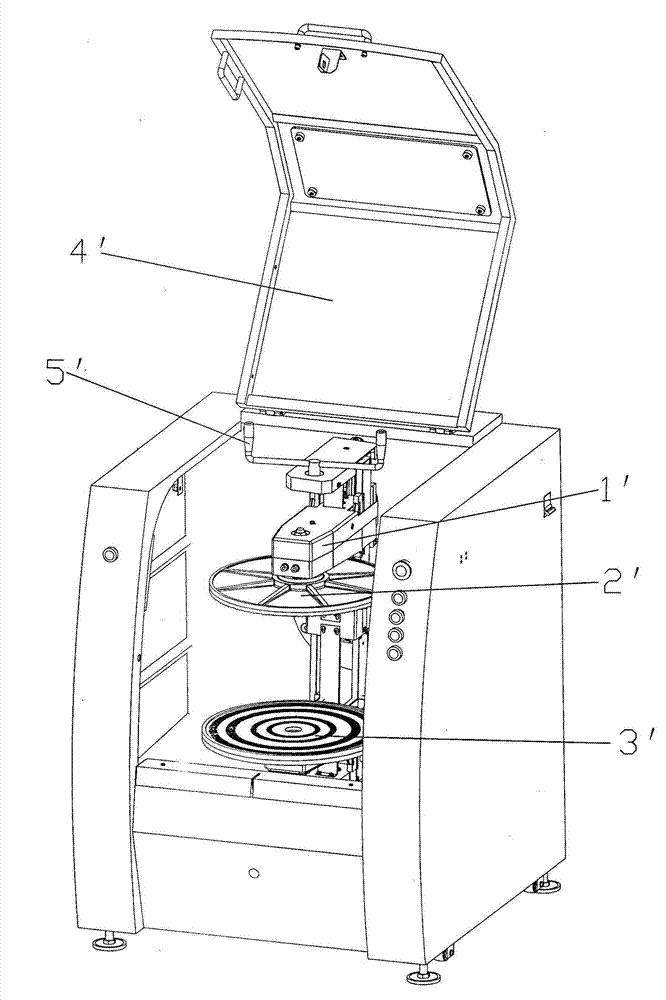

Manual pressing structure for double-rotation paint mixing machine

A compacting structure and mixer technology, applied to mixers with rotating containers, mixers, mixer accessories, etc., can solve problems such as inconvenient, dangerous machine operation, and inability for users to operate the machine, so as to achieve safe and reliable structure , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

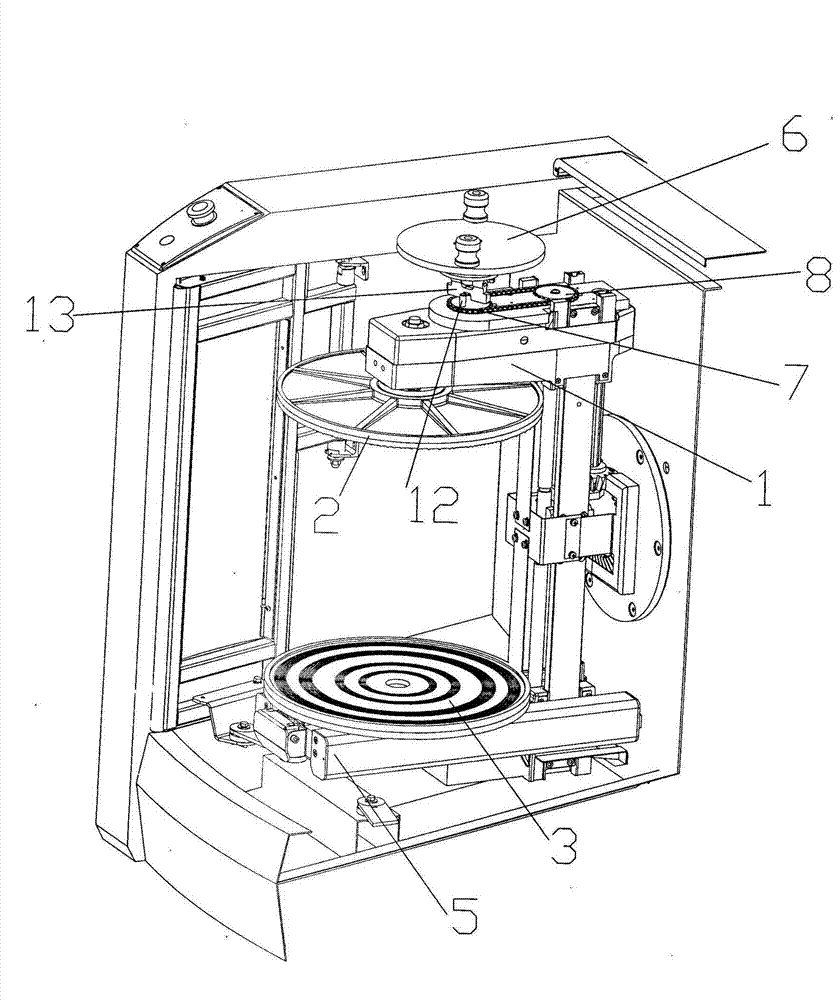

[0036] The present invention is further described below in conjunction with accompanying drawing:

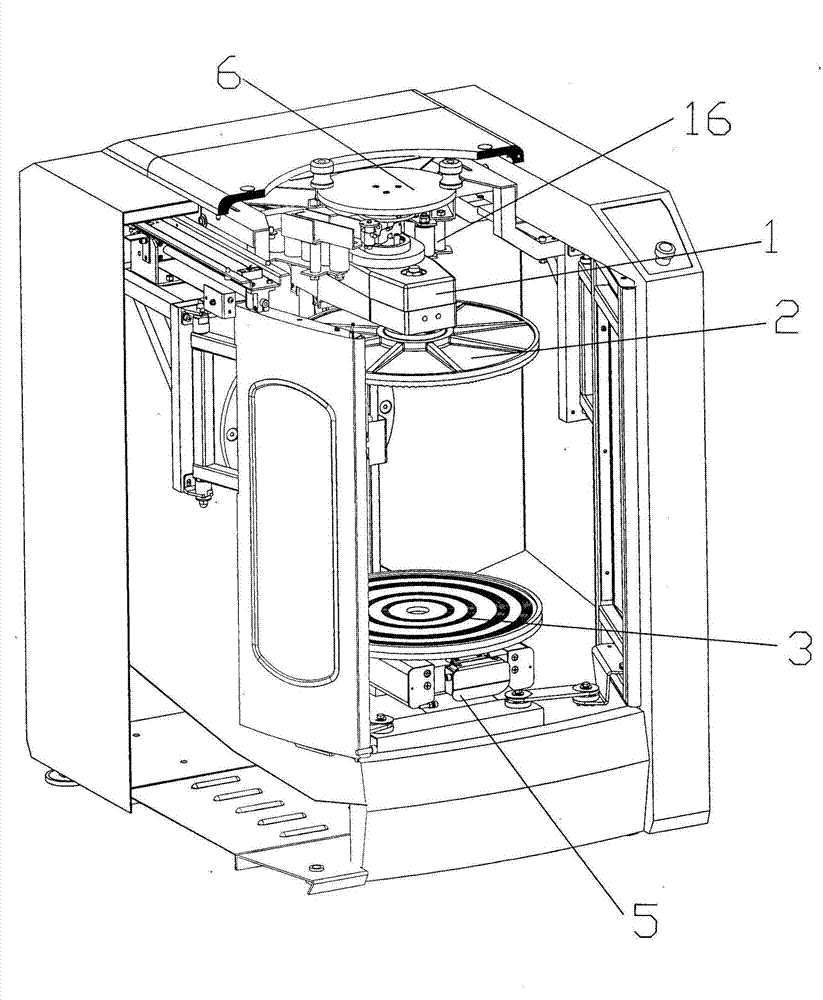

[0037] Such as Figure 2-11 Shown: the present invention is applicable to the manual pressing structure of double-rotating paint mixer, is that the manual rotating pressing assembly is installed in the top cover 4 of the mixing machine, and described manual rotating pressing assembly includes pressing The compact disc 6, the rotating shaft seat 10 and the compact disc rotating shaft 9 worn in the rotary shaft seat, the top of the compact disc rotating shaft 9 is fixedly connected with the compact disc 6, and a compact shift fork is installed at the lower end of the compact disc rotating shaft 9, The pressing driving wheel 7 of the mixer is provided with a dialed part suitable for overlapping with the pressing fork; after the machine completes the rotation and mixing of the paint, the support arm slowly stops rotating, and there is Brake mechanism makes the vertical position tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com