Large-diameter tool inductor operating under pressure

A pressurized operation, large-diameter technology, applied in measurement, wellbore/well components, earthwork drilling and production, etc., can solve problems that affect on-site operations, difficult to work, unable to implement monitoring tools, pipe string structure and external dimensions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

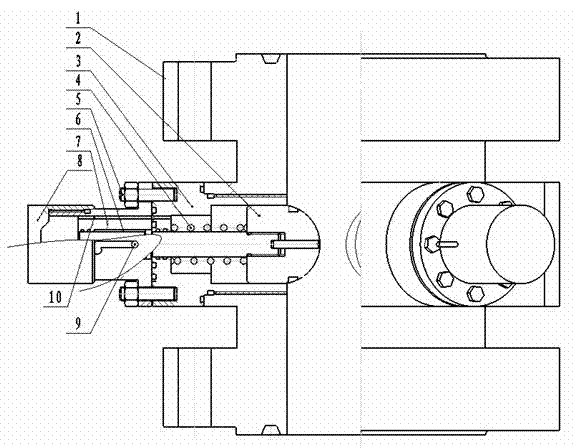

[0017] Such as figure 1 As shown, the mechanical sensor for large-diameter tools working under pressure is characterized in that: the upper end of the sensor head 2 is connected to the spring 4, one end of the mandrel 6 is connected to the sensor head 2, the other end is connected to the indicator rod 9, and the indicator rod 9 Connected with the flange 7, the pressure guide channel 10 is located in the mandrel, parallel to the axis, the induction head 2 drives the mandrel 6, and then drives the indicator rod 9.

Embodiment 2

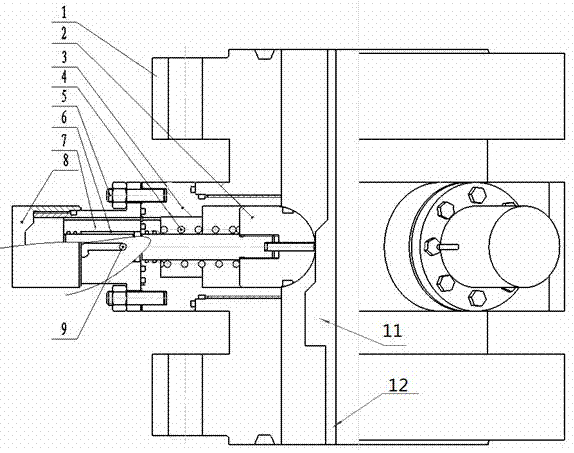

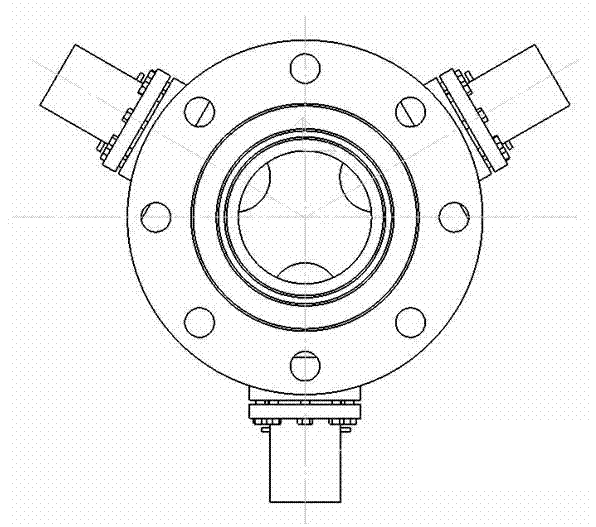

[0019] Such as figure 2 , 3 As shown, it is basically the same as Embodiment 1, the difference is that a pressure guide channel 10 is designed in the device body 1, and this channel is used to balance the pressure of the front and rear chambers of the mandrel 6, so as to avoid the high pressure in the device from affecting the core. Movement of axis 6. The pressures in the front and rear chambers of the mandrel 6 are equalized, thereby effectively avoiding the influence of the high pressure in the device on the mandrel 6 . During the drilling operation with pressure, the induction head is in direct contact with the outer surface of the tool 11. When the large-diameter tool connected to the pipe string 12 is lifted up, it will touch the induction head 2, and the large-diameter tool will touch the induction head. The head 2 and the induction head 2 will drive the mandrel 6 to recover the compression spring together, and then the indicating rod 9 will move together with the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com