Multifunctional ratchet wrench

A ratchet wrench, multi-functional technology, applied in the field of wrench tools, can solve the problems of inability to play, different sizes of disassembly and assembly space, different entry angles, etc., and achieve the effect of convenient operation, convenient packaging and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

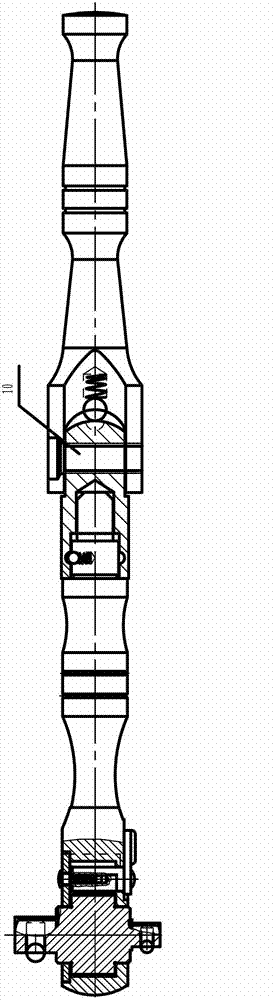

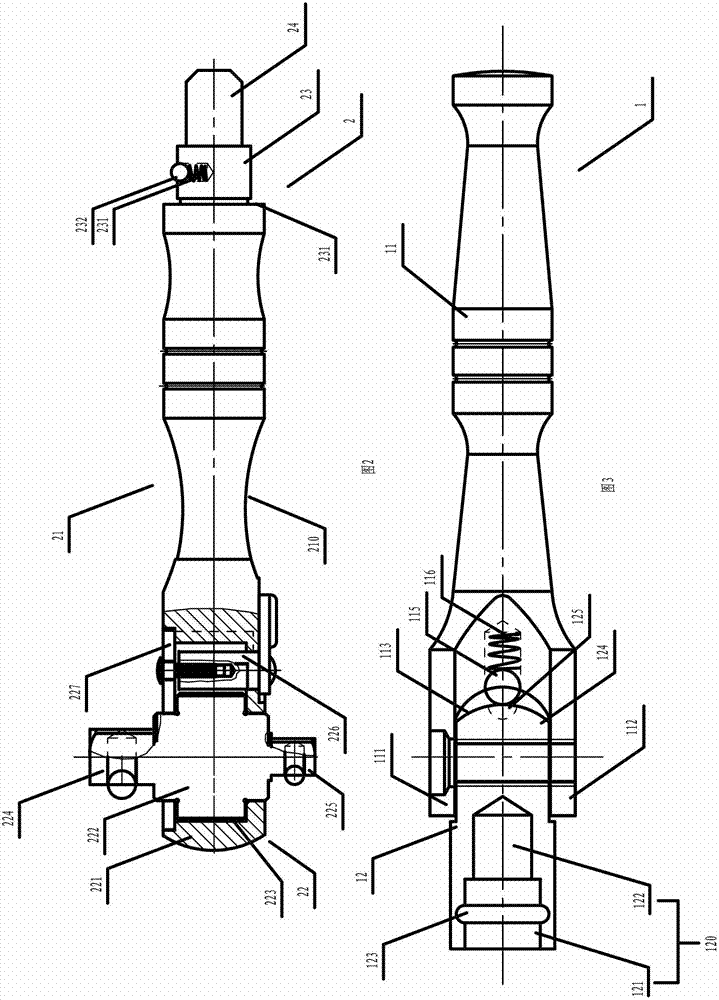

[0026] Embodiment 1, with reference to attached Figure 1-4 .

[0027] The present invention includes a conversion handle 1 and one or more tools 2 with wrenches matched with the conversion handle;

[0028] The conversion handle includes a handle 11 and a tool joint 12, the handle and the tool joint are hingedly connected, and its rotation axis 10 is perpendicular to the axial direction of the handle 11, and the tool connection end of the tool joint 12 is provided with a tool connection hole 120;

[0029] The tool 2 with a wrench includes a connecting handle 21 and a ratchet wrench mechanism 22 located at one end of the connecting handle; the connecting handle 21 has a gripping portion 210 for hand-held operation; the other end of the connecting handle is connected to the tool connecting hole 120 detachable connection, the connecting handle is provided with a connecting part 23 matching the tool connecting hole 120 at this end, the connecting part 23 transmits the torque inpu...

Embodiment 2

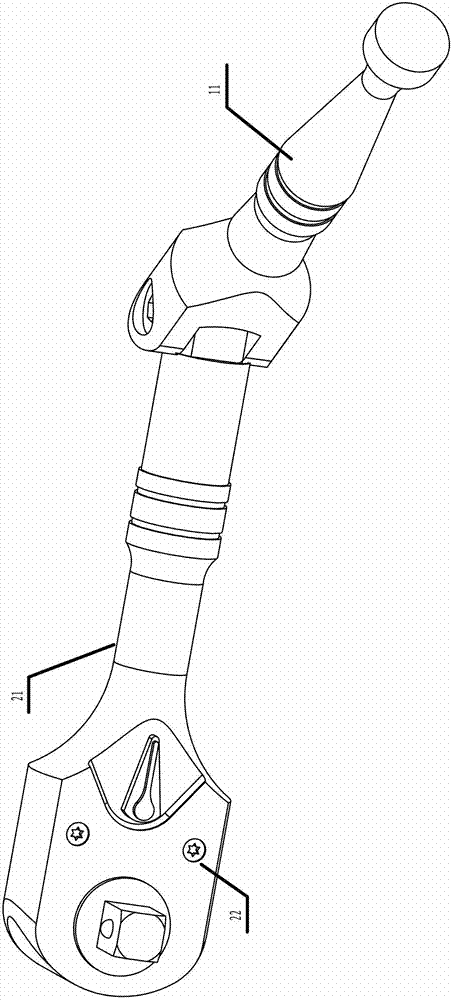

[0040]Embodiment 2, with reference to attached Figure 5

[0041] In this embodiment, the structure of the conversion handle is the same as in Embodiment 1. The tool with wrench is identical with embodiment 1.

[0042] In this embodiment, the connecting part 23 is a square wrench with a different specification from the wrench in the ratchet wrench mechanism, the protruding part is a fixed screwdriver head 25, and the fixed screwdriver head 25 is a Phillips screwdriver head, There is a limit step 231 between the tail of the square wrench and the connecting handle 21, and the connecting handle 21, the square wrench at the connecting part 23, and the set screwdriver head 25 are on the same central axis.

Embodiment 3

[0043] Embodiment 3, with reference to attached Figure 6

[0044] In this embodiment, the structure of the conversion handle is the same as in Embodiment 1. The tool with wrench is identical with embodiment 1.

[0045] In this embodiment, the connecting part 23 is a square wrench with a different specification from the wrench in the ratchet wrench mechanism, the protruding part is a fixed screwdriver head 25, and the fixed screwdriver head 25 is a Phillips screwdriver head, There is a limit step 231 between the tail of the square wrench and the connecting handle 21, the tail of the set screwdriver head has a cylinder 26 thicker than the set screwdriver head, and the cylinder 26 is at the head of the square wrench, The diameter of the cylinder 26 is shorter than the side length of the square wrench, and the connecting handle 21, the square wrench at the connection part 23, the cylinder 26, and the screwdriver head 25 are on the same central axis.

[0046] In Embodiments 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com