Universal adjustable box beam splicing and welding device

A technology of welding device and box girder, which is applied in the field of machinery, can solve the problems of low assembly precision, difficult production, time-consuming and laborious, etc., achieve good transmission force and moving ability, easy processing and maintenance, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

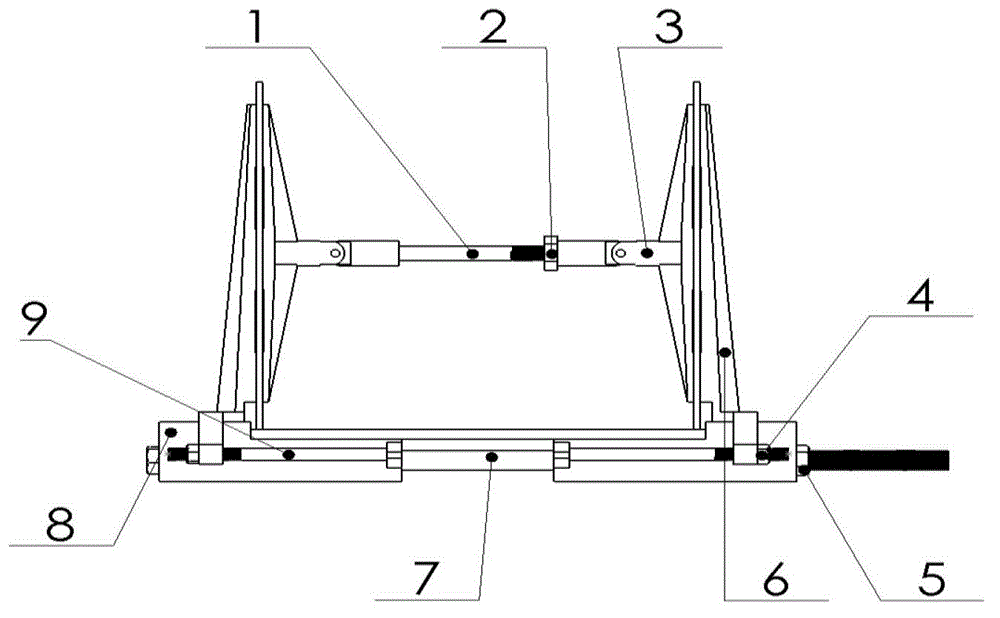

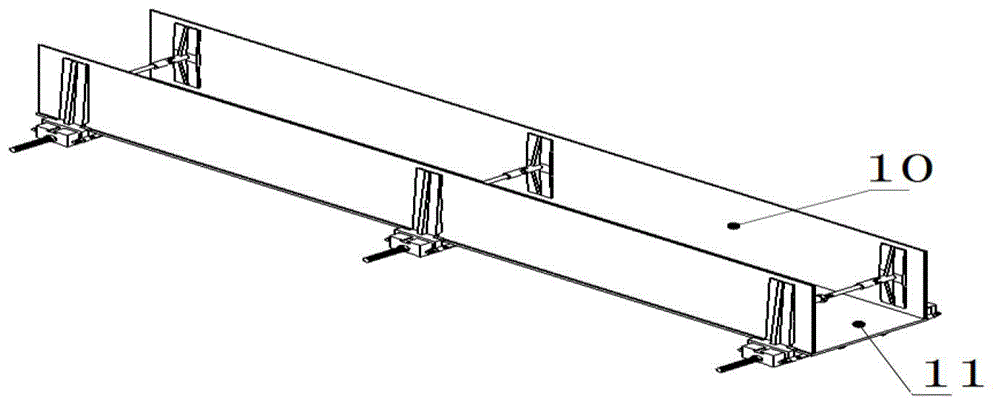

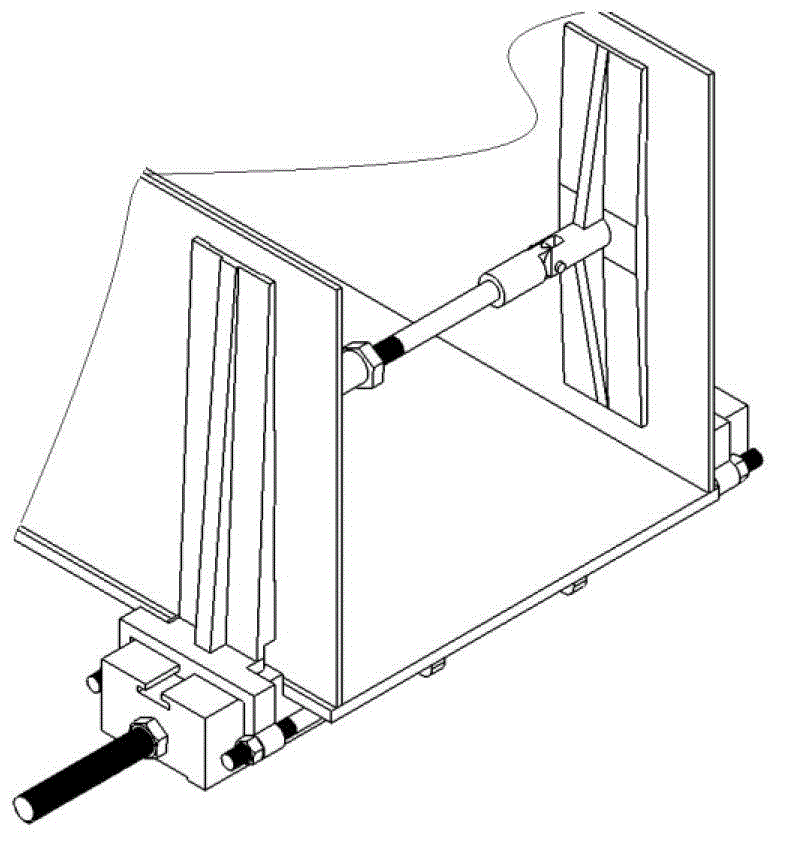

[0026] A general adjustable box girder assembly and welding device, combined with Figure 1 to Figure 10 , including a web internal clamping device 3, a web positioning device 6, a flange plate positioning clamping device 8, a web positioning device 6 including a connected bottom 15 and an upper clamping plate 16, and a T in the middle of the bottom 15 The two sides of the bottom 15 are provided with a through hole II13; the flange plate positioning clamping device 8 includes two clamping blocks 14, the center of the clamping block 14 is provided with a through hole I18, and the upper part of the through hole I18 is provided with T-shaped slot, the T-shaped protrusion and the T-shaped slot cooperate to form a double rectangular sliding track, the web positioning device 6 slides in the T-shaped slot of the clamping block 14 through the bottom 15, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com