Damage-sensing composite structures

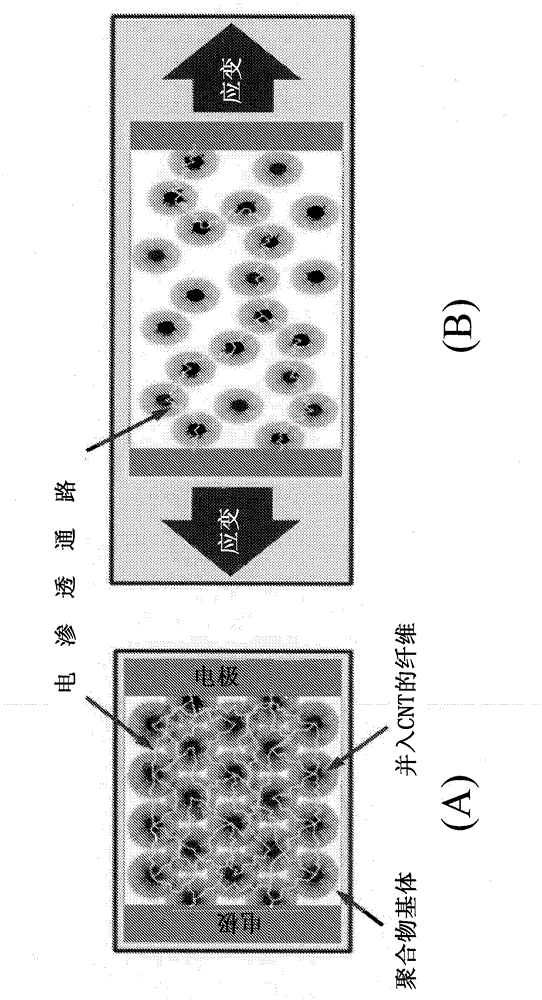

A composite material, sensing circuit technology, applied in the field of fiber materials, can solve problems such as catastrophic failure, internal damage of composite materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

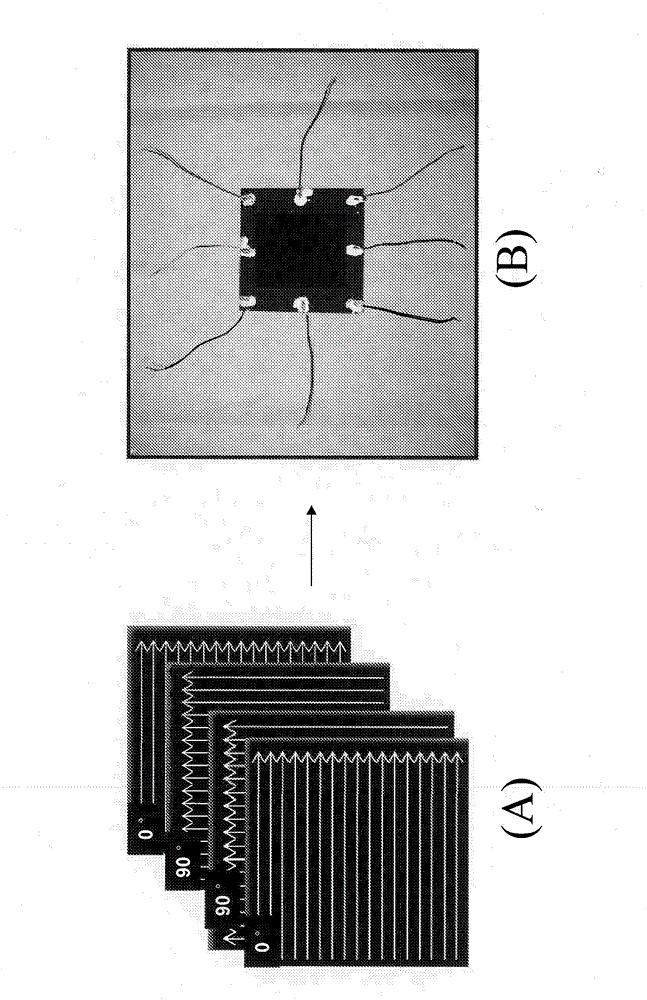

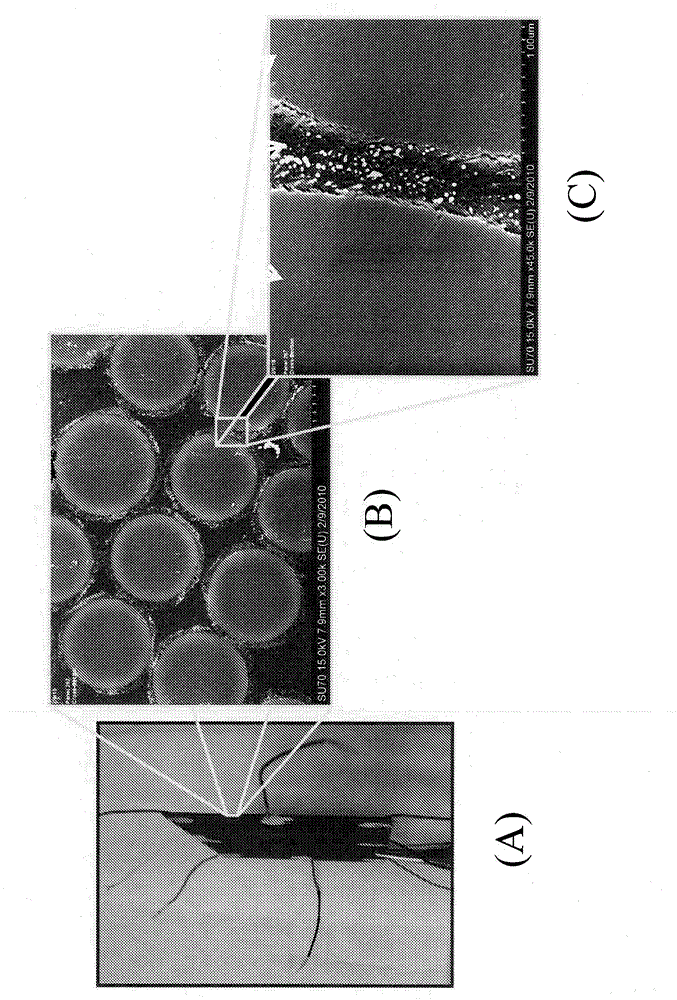

[0128] This example illustrates how CNTs can be infused into glass fiber materials in a continuous process and used in impact damage sensing applications. In this case, short CNT arrays are desirable for enhanced damage detection resolution.

[0129] Figure 14 A system 1500 for producing CNT-infused fibers according to an illustrative embodiment of the invention is described. System 1500 includes fiberglass material output and tensioning system 102, CNT-infusion system 112, and fiber winder 124, interrelated as shown.

[0130] The output and tensioning system 102 includes an output bobbin 104 and a tensioner 106 . The output bobbin holds the fiber roll and delivers the fiberglass material 101 to the process at a line speed of 9 ft / min; fiber tension is maintained at 1-5 lbs by tensioner 106. Delivery and tensioning stations 102 are conventional in the fiber industry; their design and use will be familiar to those skilled in the art.

[0131] The tensioned fiber 105 is del...

Embodiment II

[0141] This example shows how CNTs can be infused into glass fiber materials in a continuous process and used for impact damage sensing applications. In this case, short CNT arrays are desirable for enhanced damage detection resolution.

[0142] Figure 14 A system 1500 for producing CNT-infused fibers according to an illustrative embodiment of the invention is described. System 1500 includes fiberglass material output and tensioning system 102, CNT-infusion system 112, and fiber winder 124, interrelated as shown.

[0143] The output and tensioning system 102 includes an output bobbin 104 and a tensioner 106 . The output bobbin holds the fiber roll and delivers the fiberglass material 101 to the process at a line speed of 12 ft / min; fiber tension is maintained at 1-5 lbs by tensioner 106. Delivery and tensioning stations 102 are commonly used in the fiber industry; those skilled in the art will be familiar with their design and use.

[0144] The tensioned fiber 105 is deli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com