Facility for automatically collecting waste liquid in volumetric flasks

An automatic collection and volumetric bottle technology, which is used in emptying containers, bottle filling, liquid treatment, etc., can solve the problems of time-consuming and laborious recycling and collection of waste liquid, physical harm to workers, and heavy labor for workers. Hazards, easy post-processing, and the effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

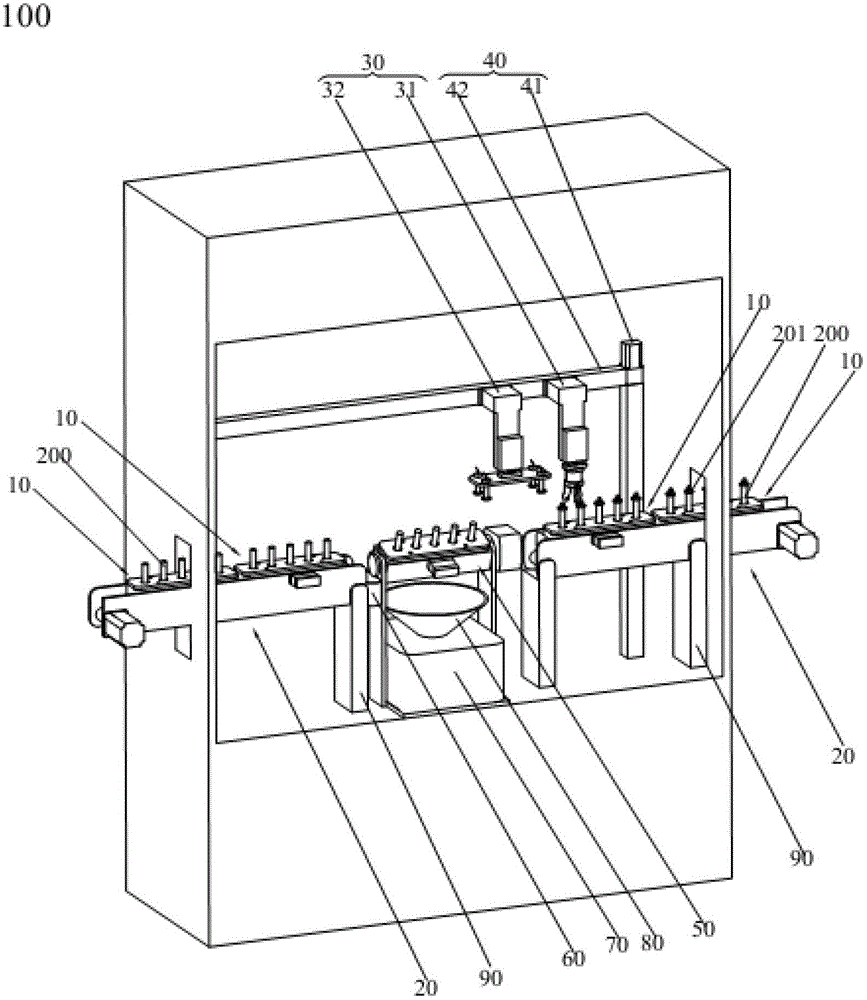

[0022] The present invention will be further described below in conjunction with the accompanying drawings. The technical solution adopted in the present invention is: a volumetric flask waste liquid automatic collection device 100, such as figure 1 , 2 As shown, it includes a fixing device 10, a power transmission device 20, a single-axis robot 40, a handling device 30, and a rotating fixture 50:

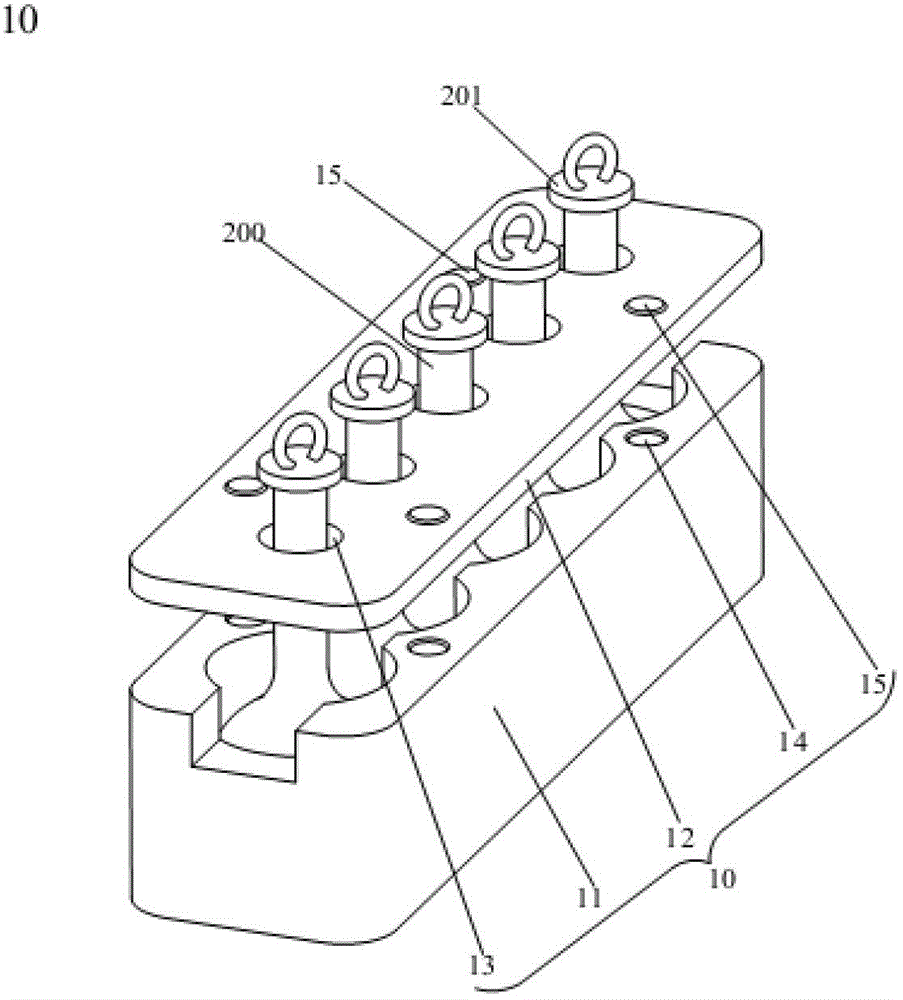

[0023] The volumetric flask waste liquid automatic collection device 100, the fixing device 10 includes a container box 11, a container cover 12, such as image 3 As shown, the container box 11 can place a plurality of containers 200, covered by the container cover 12 with holes to form a whole fixing device 10, which can pour out waste liquid at one time and improve work efficiency; a set of volumetric bottle waste liquid The automatic collection device 100 is provided with multiple sets of fixing devices 10 of different models, which can improve work efficiency and has strong pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com