Three-dimensional continuous roller tea-leaf cooling and moisture regaining machine

A drum cooling, three-dimensional technology, which is applied in the field of tea three-dimensional continuous drum cooling and moisture regaining machine, can solve the problems of not meeting the needs of automated production lines, large floor space, cumbersome adjustment of inclination angle, etc., to meet the needs of automated production lines, occupy an area of Small size, the effect of improving plant utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

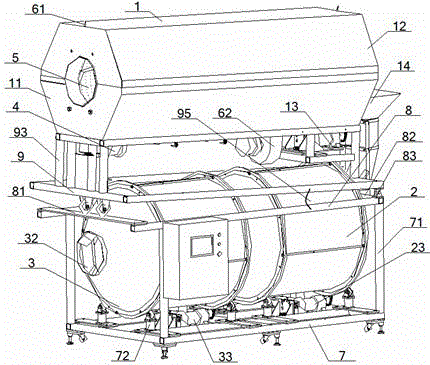

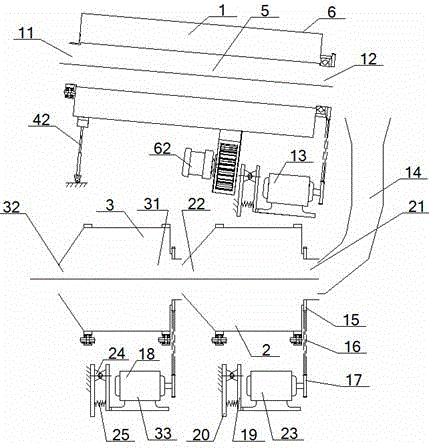

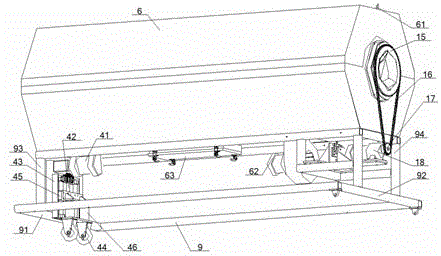

[0051] see figure 1 – Image 6 , a three-dimensional continuous drum cooling and resurfacing machine for tea, comprising a cylindrical cooling chamber 1, a transition chamber 2 and a resurgence chamber 3, the transition chamber 2 and the resurgence chamber 3 are located on the same horizontal line, and the cooling chamber 1 is arranged in the transition chamber 2, Above the moisture resurgence chamber 3, the cooling discharge end 12 of the cooling chamber 1 communicates with the transition feed end 21 through the vane bucket 14, and the transition discharge end 22 of the transition chamber 2 communicates with the moisture resurgence feed end 31 of the moisture resurgence chamber 3, and the transition The bottoms of the chamber 2 and the dampening chamber 3 are connected with the bottom frame 7 through the follower support assembly 72, and the four corners of the bottom frame 7 are connected with the bottom of the top frame 8 through vertical beams 71. The inside of the top fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com