Refrigerator

A technology for refrigerators and outer boxes, which is applied in the field of refrigerators made of vacuum insulation materials. It can solve the problems of narrow intervals, offset of fixed positions, and increased power consumption of refrigerators, so as to achieve the effect of restraining deflection and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, the present invention will be described with reference to the illustrated embodiments.

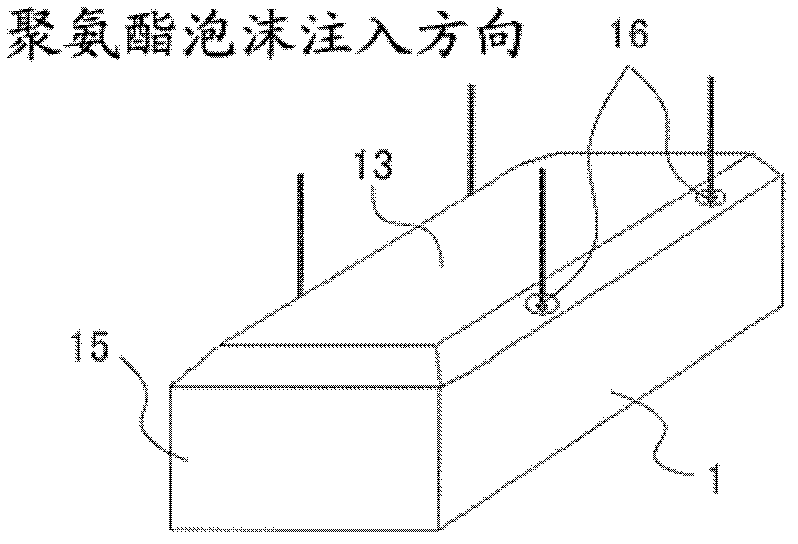

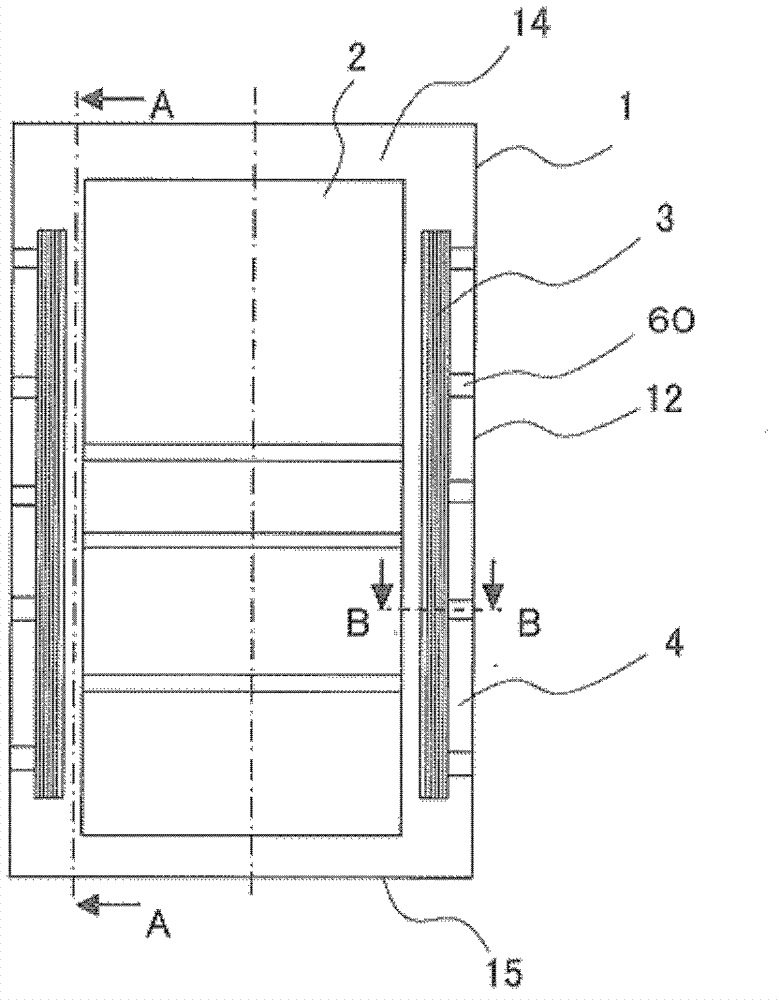

[0032] figure 1 It is a schematic explanatory drawing at the time of pouring the polyurethane foam of the refrigerator which concerns on embodiment of this invention. figure 2 It is a schematic explanatory drawing of the polyurethane foam flow at the time of foaming the polyurethane foam of the refrigerator which concerns on embodiment of this invention. The refrigerator of the embodiment of the present invention such as figure 1 and figure 2 As shown, the box is integrally formed with an outer box 1 made of metal such as iron and an inner box 2 made of synthetic resin such as ABS ( image 3 ), install the enclosure with the door side facing down. The outer box 1 has side surfaces formed by side panels 12 , a rear surface formed by rear panels 13 , and a bottom surface formed by bottom panels 15 . When injecting polyurethane foam, make the back side of outer cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com