Storage bin automatic detection blockage clearing device

An automatic detection and blockage removal technology, applied in the field of material silos, can solve the problems of increased frictional resistance of the warehouse wall, labor consumption, and large damage to the warehouse wall, and achieve the effect of preventing material blockage, easy installation, and large area for clearing blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

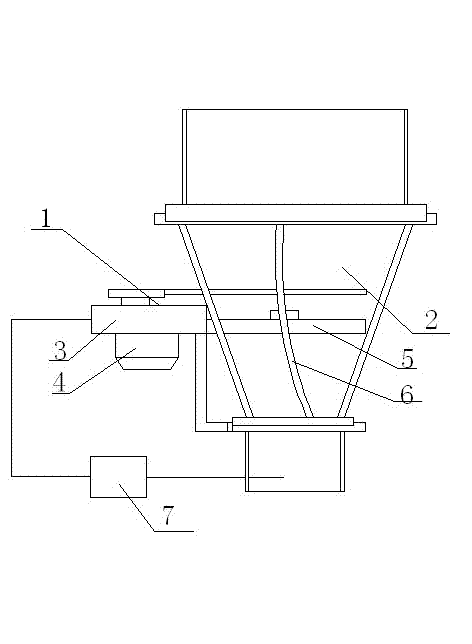

[0013] The silo automatic detection blockage removal device is composed of a silo blockage removal device 1 and an automatic control system connected thereto. The fixed platform 3, the reducer 4, the support frame 5, the gear and the arch-breaking and blocking-clearing blade 6 are composed. The reducer 4 is installed on the fixed platform 3, and one end of the gear is connected with the reducer 4 through a coupling , the other end is connected to at least one arch-breaking and blocking-removing blade 6 through a rotating shaft, the fixed platform 3 is connected to the flange of the lower hopper section, and the arch-breaking and blocking-removing blade 6 is fixed on the lower part through the support frame 5 The interior of silo section 2.

[0014] There are three arch-breaking and blockage-clearing blades 6 in the present invention, which have a turning gap with the lower bin section 2, and the blades are in the shape of a spiral, a straight plate or an inclined plate.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com