Quick clamping mechanism

A technology of quick clamp and output shaft, which is applied in the directions of motor tools, portable motor devices, manufacturing tools, etc., can solve problems such as inconvenience of operation, and achieve the effect of ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

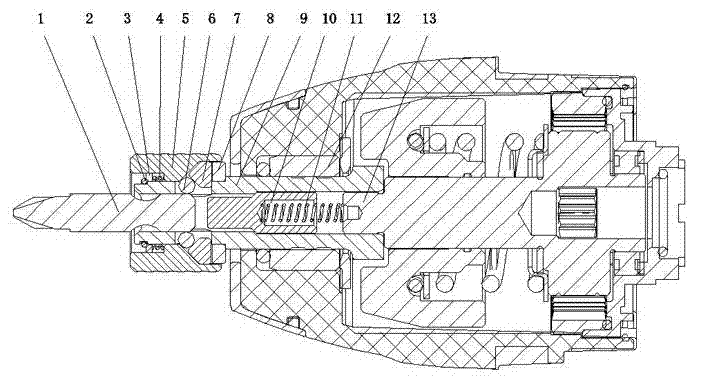

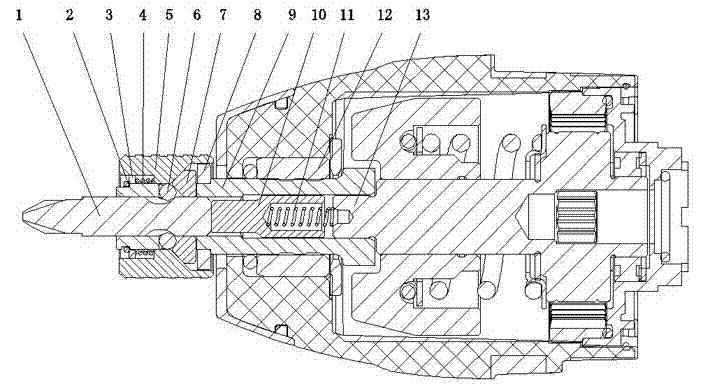

[0029] Below in conjunction with accompanying drawing and specific embodiment, promptly take electric screwdriver as example, the present invention is made concrete introduction.

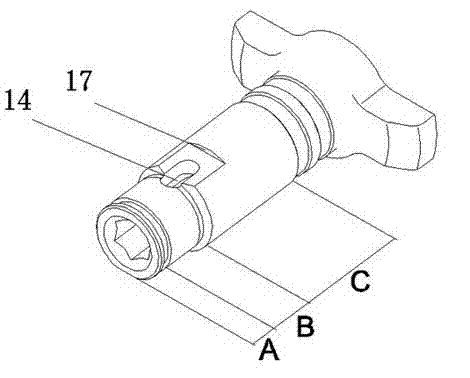

[0030] refer to Figure 1 to Figure 5 As shown, a quick clamping mechanism of the present invention mainly includes: a locking member 6 , a movable member 7 , an anvil 9 , and a bushing 5 .

[0031] Wherein, the locking piece 6 is used to cooperate with the locking groove 18 of the working attachment 1. Preferably, the locking piece 6 can be made of metal material in order to ensure the structural strength. The center of hammer anvil 9 is provided with a placement cavity, and the effect of placement cavity is to insert the working accessory 1 and accommodate the slide pin 10. The placement cavity can be designed as a through cavity with both ends connected or as a cavity with one end open. The hammer anvil 9 is used for inserting One end of the working accessory 1 is figure 1 The left end shown is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com