Preparation method of high-catalytic efficiency and recyclable photocatalyst

A technology of catalytic efficiency and photocatalyst, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve difficult recovery and reuse, low photocatalyst catalytic efficiency and other problems to achieve the effect of improving utilization efficiency, facilitating recycling and reuse, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing a recyclable photocatalyst with high catalytic efficiency, comprising the steps of:

[0021] (1) put x Carbonaceous particles with a gram size of less than 10nm or graphene with a thickness of less than 10 carbon atoms are refluxed in 0.5mol / L nitric acid for 3 hours to obtain a carbon nanoparticle suspension v liter; add y grams of sodium alginate to the carbon nanoparticle suspension and stir vigorously to obtain a mixed solution; where: x: v = 1:5, v:y = 1:4;

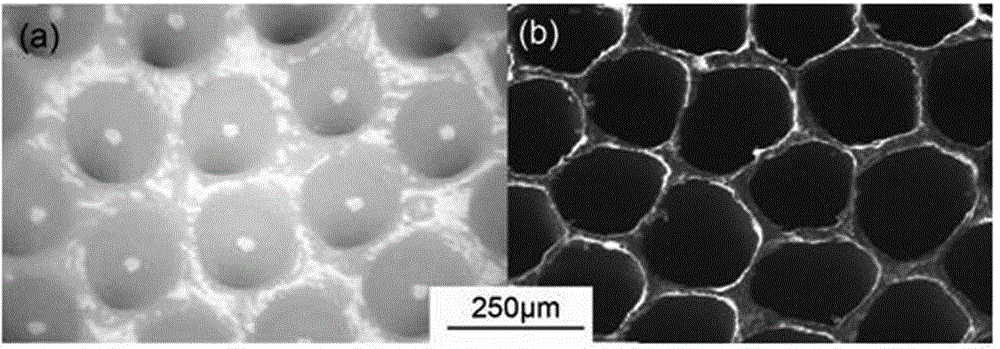

[0022] (2) Pour a liter of the above mixed solution into the container so that the height of the liquid level is 4 mm, and evenly spray b liter of 5 mol / L copper chloride or copper sulfate solution on the surface of the mixed solution; the seaweed in the mixed solution When acid radical ions encounter divalent copper ions, they will produce gel and shrink to form through holes along the permeation path of divalent copper ions. After 2 hours of reaction, a copper alginate gel with a th...

Embodiment 2

[0025] A method for preparing a recyclable photocatalyst with high catalytic efficiency, comprising the steps of:

[0026] (1) put x Carbonaceous particles with a gram size of less than 25nm or graphene with a thickness of less than 10 carbon atoms are refluxed in 2.8mol / L nitric acid for 5 hours to obtain a carbon nanoparticle suspension v liter; add y grams of sodium alginate to the carbon nanoparticle suspension and stir vigorously to obtain a mixed solution; where: x: v = 1:0.1, v:y = 1:27;

[0027] (2) Pour a liter of the above mixed solution into the container and make the liquid level 12mm, and evenly spray b liter of 2.6 mol / L copper chloride or copper sulfate solution on the surface of the mixed solution; the alginate in the mixed solution When the ions encounter divalent copper ions, they will produce gel and shrink to form through holes along the permeation path of divalent copper ions. After 3 hours of reaction, a copper alginate gel with a through hole structur...

Embodiment 3

[0030] A method for preparing a recyclable photocatalyst with high catalytic efficiency, comprising the steps of:

[0031] (1) put x Carbonaceous particles with a gram size of less than 15 nm or graphene with a thickness of less than 10 carbon atoms are refluxed in 1.5 mol / L nitric acid for 7 hours to obtain a carbon nanoparticle suspension vliter; add y grams of sodium alginate to the carbon nanoparticle suspension and stir vigorously to obtain a mixed solution; where: x: v = 1:2.5, v:y = 1: 50;

[0032] (2) Pour a liter of the above mixed solution into the container so that the height of the liquid level is 8 mm, and evenly spray b liter of 4 mol / L copper chloride or copper sulfate solution on the surface of the mixed solution; the seaweed in the mixed solution When acid radical ions encounter divalent copper ions, they will produce gel and shrink to form through holes along the permeation path of divalent copper ions. After 4 hours of reaction, a copper alginate gel with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com