Composite,fabrication and recovery methods thereof, catalyst, antibiosis or antiviral compounds

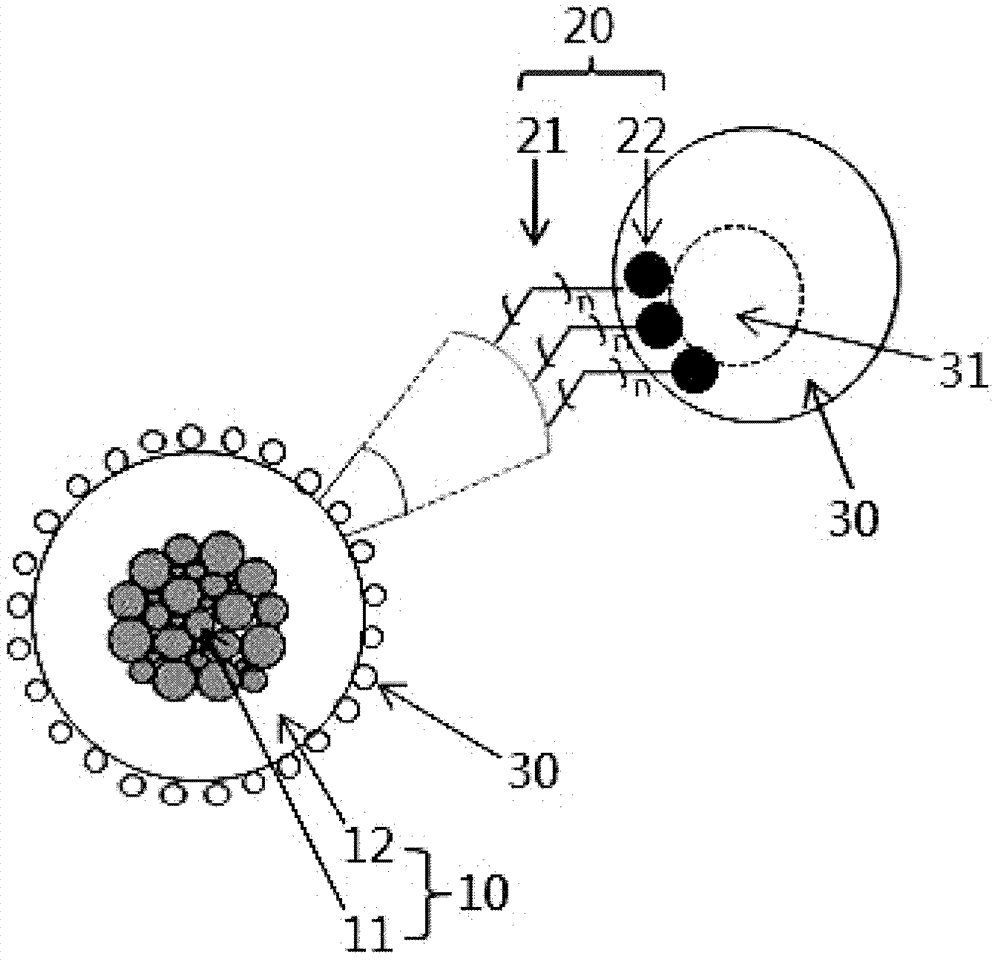

一种复合物、前驱物的技术,应用在环境友好多孔珠-卫星纳米颗粒复合物及其制备领域,能够解决难以回收纳米颗粒、未出现等问题,达到易于回收和重新使用的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Preparation of Porous Bead-Silver Satellite Nanoparticle Composite with Magnetic Core, Porous Bead Shell, and Silver Satellite Nanoparticles Bonded to the Surface of the Porous Bead Shell

[0050] (1) The first step: the preparation of the core of superparamagnetic nanoparticles structured as clusters

[0051] According to the method described in the literature (Angewandte Chemie International Edition 2009, 48, 5875-5879), the FeCl 3 (0.65g, 4.0mmol) and trisodium citrate (0.20g, 0.68mmol) were dissolved in 20ml of ethylene glycol, then sodium acetate (1.20g) was added and stirred for 30 minutes. The solution was transferred to an autoclave, sealed, and reacted in an oven at a temperature of 200° C. for 14 hours to prepare a core configured as clustered superparamagnetic nanoparticles. The solution was cooled at room temperature, the clusters were washed once with ethanol and distilled water respectively, collected with a magnet and dispersed in 20 ml of eth...

Embodiment 2

[0059] Example 2: Preparation of Porous Bead-Gold Satellite Nanoparticle Composite with Magnetic Core, Porous Bead Shell, and Gold Satellite Nanoparticles Bonded to the Surface of the Porous Bead Shell

[0060] The first to third steps in Example 1 were performed in the same manner, and the gold satellite nanoparticles were bound to the surface of the magnetic core-porous bead shell in the same manner as the fourth step. 2ml HAuCl 4 4H 2 O solution (2wt / v%) and 5ml NaOH solution (0.1M) were put into 45ml water and stirred, slowly mixed into 0.012ml THPC (80wt%) to generate gold nanoparticle seeds. 20ml of the gold nanoparticle seed solution in the resulting total solution was mixed with 2ml of the magnetic core-porous bead shell solution bound with amine groups to allow the small gold nanoparticle seeds to bind to the amine groups on the surface of the silica shell. By applying 20ml HAuCl 4 4H 2 O solution (0.01wt / v%) and 0.05ml formaldehyde were stirred and the gold nanop...

Embodiment 3

[0061] Example 3: Preparation of silica porous beads-silver nanoparticle composite without magnetic core

[0062] The first and second steps of Example 1 were omitted, and the third and fourth steps were performed on the silica beads to bind silver nanoparticles to the surface of the silica beads without magnetic cores therein.

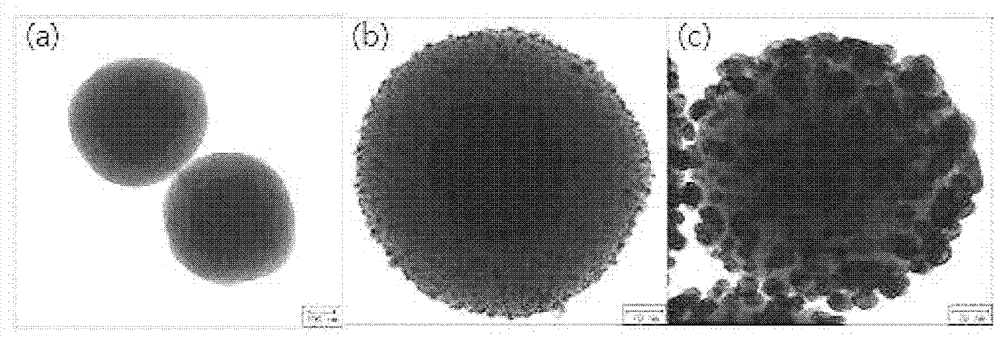

[0063] by using Methods To prepare silica beads, add 50ml of distilled water and 15ml of ammonia water to 500ml of ethanol, stir for one minute, add 60ml of TEOS, and stir at 20°C for 15 hours. After the reaction was completed, the silica beads were washed three times with ethanol, and dispersed in 1000 ml of ethanol. After TEM image inspection, the size of the synthesized silica beads was ~480 nm, as Figure 6 In (a) shown.

[0064] In order to attach silver nanoparticles to the surface of silica beads, amine groups were bound to the surface of silica beads in the same manner as in the third step in Example 1. For this, 500 ml of synthetic silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com