heating cooker

A technology of cooker and heating unit, which is applied in the direction of cooking utensils, special materials for cooking utensils, household utensils, etc., which can solve the problem that the uneven heating in the pot cannot be alleviated, and achieve the effect of promoting uniform cooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

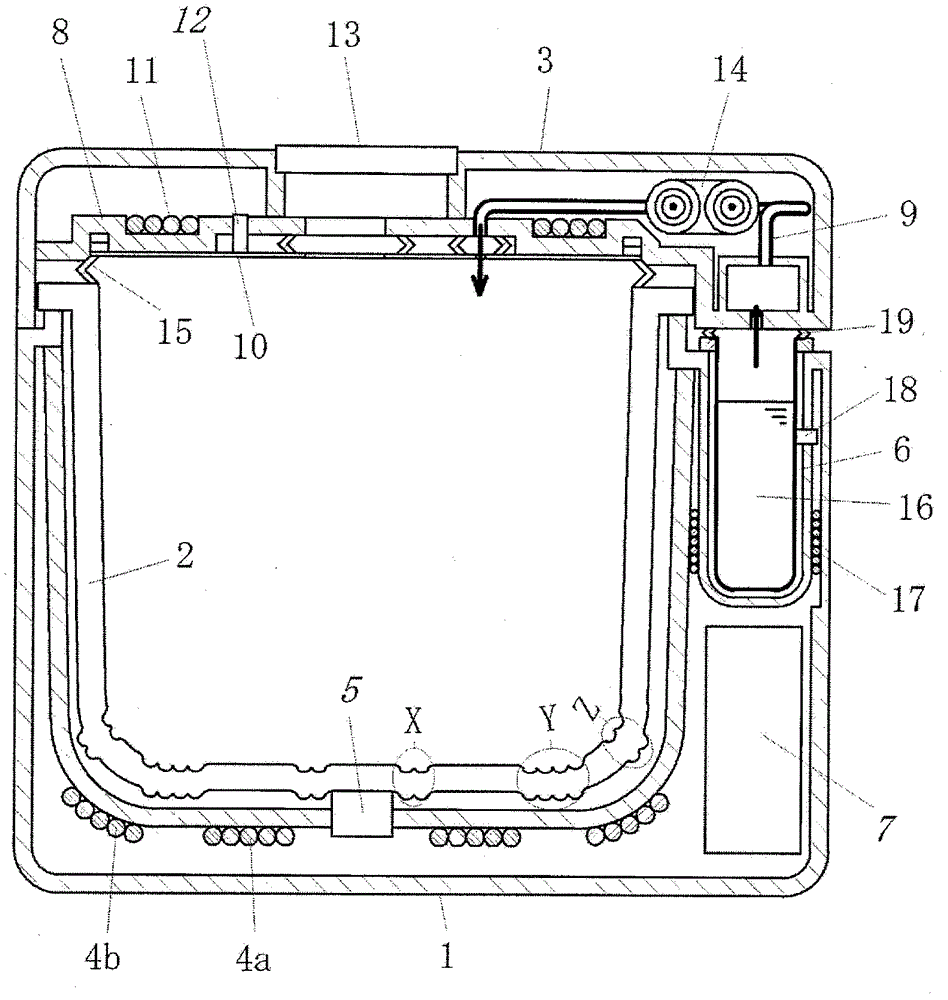

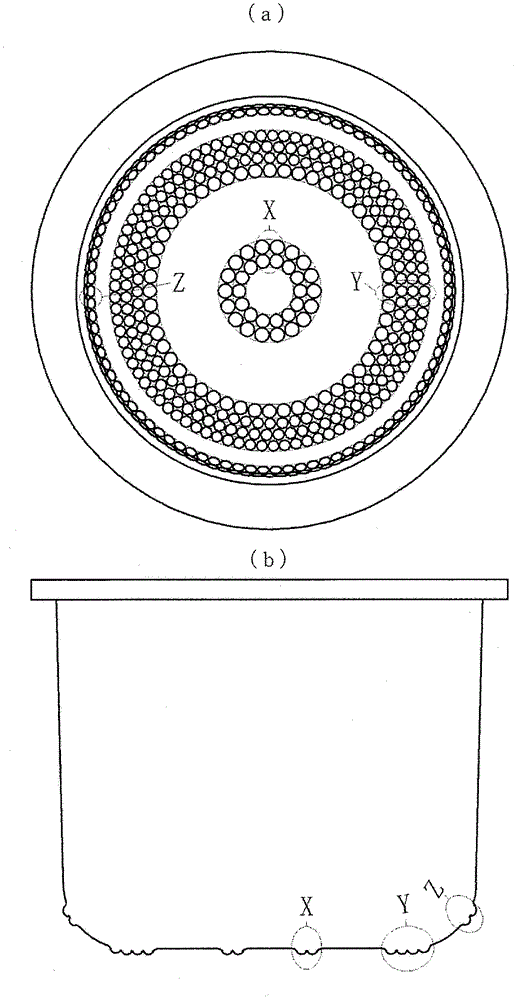

[0072] figure 1 It is a sectional view of the rice cooker in Embodiment 1 of this invention. figure 2 It is a figure which shows the pot in Embodiment 1 of this invention, wherein, figure 2 (a) is a top view, figure 2 (b) is the main view. image 3 It is an enlarged cross-sectional view showing a main part of the pan bottom surface in Embodiment 1 of the present invention.

[0073] exist figure 1 Among them, the main body 1 of the rice cooker is equipped with a pot 2 which can be freely attached and detached. A cover 3 covering the upper surface of the main body 1 is provided on the main body 1 in a freely openable and closable manner.

[0074] The main body 1 has: pot heating units 4a and 4b, which are used to inductively heat the pot 2; a pot temperature detection unit 5, which is used to detect the temperature of the pot 2; a steam generating unit 6, which is used to generate steam; and control unit7. In this embodiment, an induction heating coil is used as an e...

Embodiment approach 2

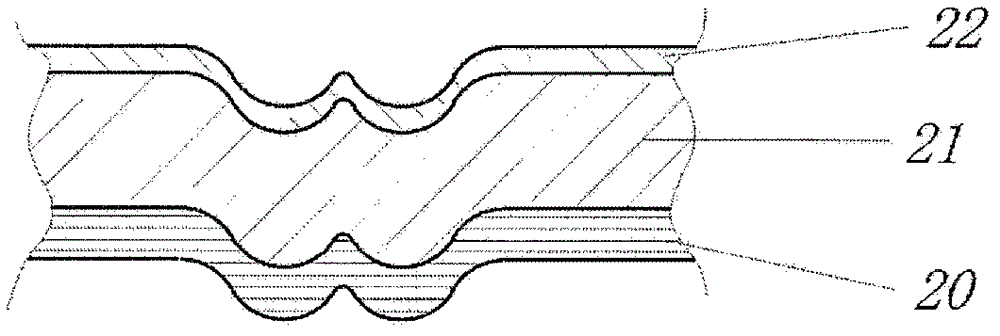

[0125] Figure 4 It is an enlarged cross-sectional view showing a main part of the pot bottom surface in the rice cooker according to Embodiment 2 of the present invention. In addition, the same code|symbol is attached|subjected to the same part as Embodiment 1, and description is abbreviate|omitted.

[0126] Such as Figure 4 As shown, in the rice cooker of the present embodiment, the fluororesin coating layer 22 has the additive particles A concentrated in the lowermost portion of the concave portion (concave shape of the inner surface of the pot 2 with unevenness). The additive particles A contain at least one of silicon carbide and diamond. With such a structure, boiling from the concave portion is promoted, whereby uniform heat transfer to rice can be realized by boiling heat transfer.

[0127] Fluoroplastic is a material with low thermal conductivity, while silicon carbide and diamond are materials with extremely high thermal conductivity. That is, in the case of usi...

Embodiment approach 3

[0131] Figure 5 An enlarged cross-sectional view showing a main part of a pot bottom surface in a rice cooker according to Embodiment 3 of the present invention, Image 6 An enlarged perspective view showing the fluororesin coating on the bottom surface of the pot in the rice cooker according to Embodiment 3 of the present invention. In addition, the same code|symbol is attached|subjected to the same part as Embodiment 2, and the description is abbreviate|omitted.

[0132] Such as Figure 5 , Image 6 As shown, a plurality of micropores B in the shape of polygonal pyramids are formed in the surface layer of the fluororesin coating 22 at positions other than the concave and convex portions. In addition, the additive particles C are concentrated on the surface layer of the fluororesin coating 22, and are most numerous in the lowermost portion of the fine pores B. Like the additive particles A, the additive particles C contain at least one of silicon carbide and diamond. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com