Orchard self-propelled lifting operation platform

A work platform, self-propelled technology, applied in the direction of lifting devices, etc., can solve the problems of high risk, poor operation comfort, low production efficiency, etc., and achieve the effects of flexible walking, free rotation and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

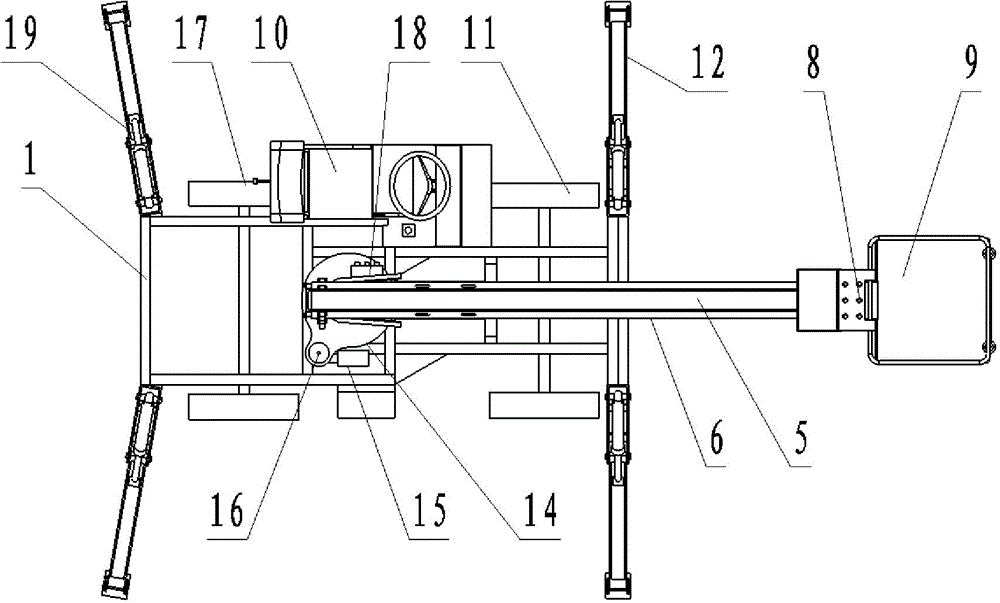

[0015] Embodiment 1: This embodiment includes a hydraulic system, a traveling mechanism, and an engine (13), and is provided with a rotating device, a lifting device, an operating platform, and a working table. The rotating device includes a rotating assembly and a rotating column (3), and the rotating assembly It includes a hydraulic motor (15), a worm gear reduction mechanism (16), and a slewing ring bearing (14). The slewing ring bearing adopts an external gear type, embedded and fixed on the surface (20) of the walking chassis (1), and the outer surface of the slewing ring bearing The ring gear (23) is fixed on the chassis (1), the inner ring of the slewing support shaft (22) is fixed together with the lower end surface (21) of the rotating column, and the hydraulic motor (15) and the worm gear box are fixed on the rotating column (3). Above, the worm (26) is connected with the hydraulic motor (15) through a coupling (27), and the pinion (24) at the end of the worm gear sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com