2M cable tester

A tester and cable technology, which is applied in the field of 2M cable tester, can solve the problems that the accuracy of cable testing is difficult to guarantee, and the 2M connector cannot be detected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

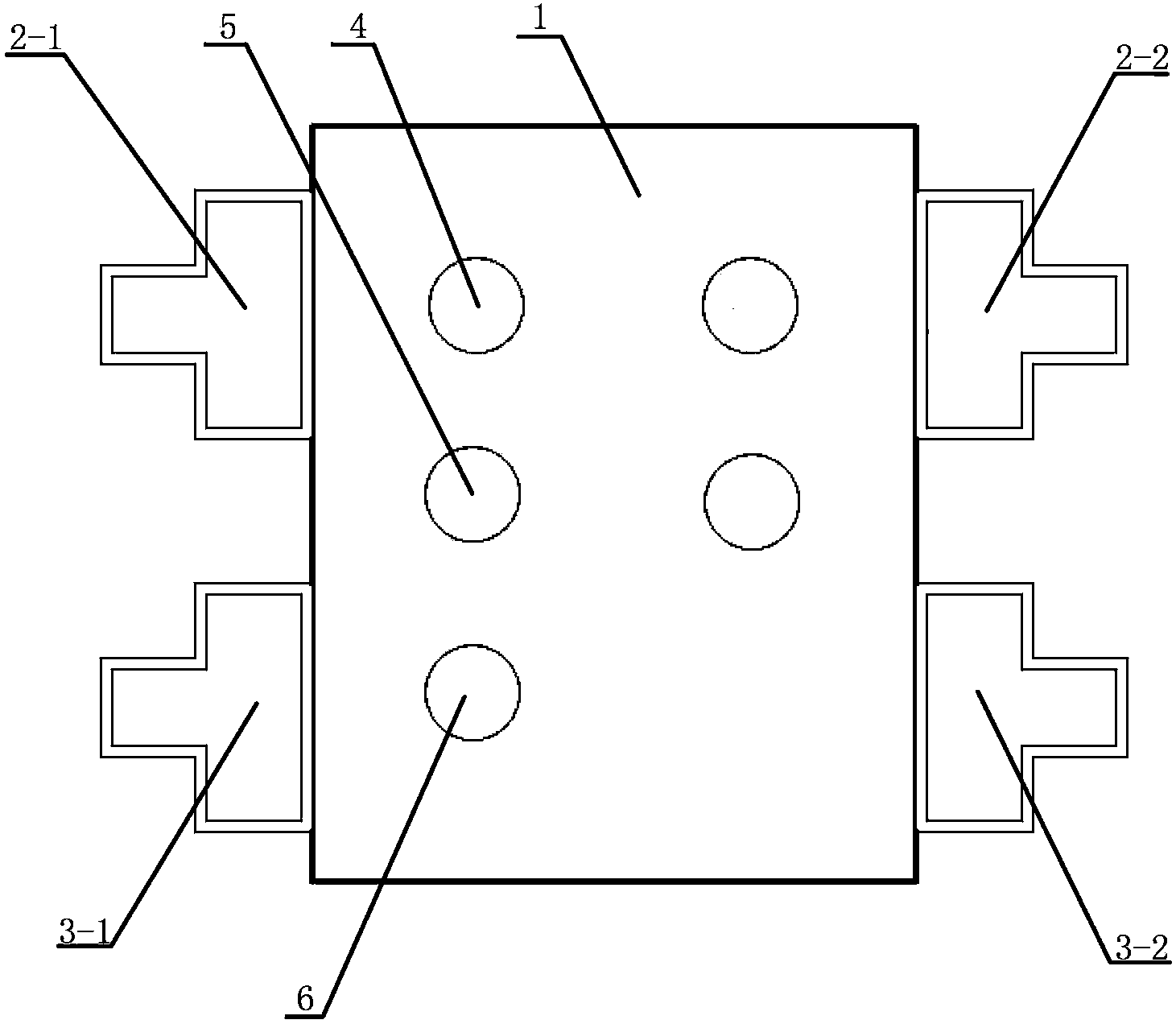

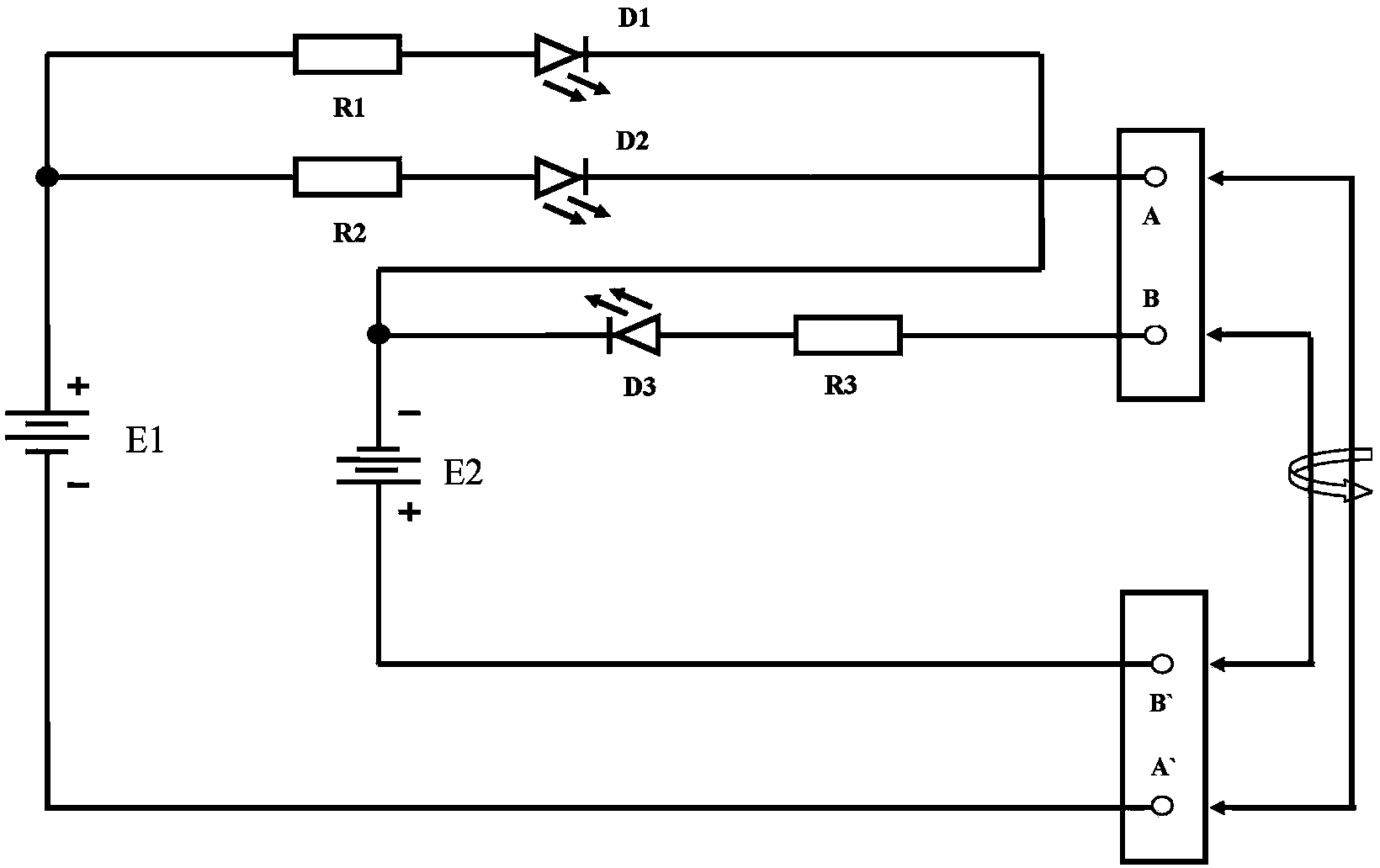

[0013] As attached figure 1 , 2 As shown, the present invention includes a housing 1 and a pair of Siemens 2M line interfaces 2-1, 2-2 and a pair of BNC2M line interfaces 3-1, 3-2 arranged on the housing 1. The cable core on-off indicator light 4, the shielding layer on-off indicator light 5 and the short-circuit indicator light 6 are provided. The housing 1 is provided with a 2M cable detection circuit. The 2M cable detection circuit is composed of a core detection unit and a shield It consists of a layer detection unit and a cable short-circuit detection unit.

[0014] The core detection unit is composed of a battery E1, a current-limiting resistor R2, and a light-emitting diode D2. The current-limiting resistor R2 is connected in series with the light-emitting diode D2 and then connected to the core end of the positive electrode of the battery E1 and the Siemens 2M line interface and the BNC2M line interface , The wire core terminal of the Siemens 2M line interface and the BNC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com