Sheet stamped part

A stamping and sheet-like technology, applied in the direction of supporting machines, mechanical equipment, machines/stands, etc., can solve the problems of scratches on the fixed base of the LCD screen, affecting the quick fixation of the LCD screen, and bumping the installers, etc., and achieve good application. Prospect, easy plug-in, stable configuration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

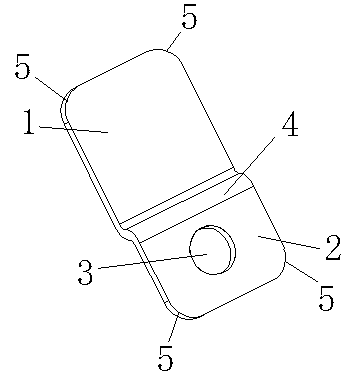

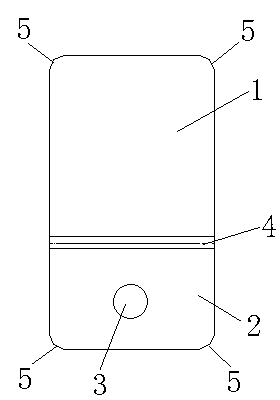

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] Such as figure 1 and figure 2 As shown, a sheet-shaped stamping part includes an integrally formed upper sheet-shaped stamping body 1 and a lower sheet-shaped stamping body 2, wherein the upper sheet-shaped stamping body 1 is used to insert into the fixing base of the LCD screen, and the lower sheet-shaped stamping body 2 passes through The mounting hole 3 arranged in its center is fixed to the liquid crystal screen, and the connection between the upper sheet-shaped stamping body 1 and the lower sheet-shaped stamping body 2 is an arc-shaped corner 4, and the angle formed by the two sides of the arc-shaped corner 4 is 90 degrees, so that After the upper sheet-shaped stamping body 1 is inserted into the liquid crystal screen fixing base, the arc-shaped corner 4 can be stuck on the upper end of the liquid crystal screen fixing base to ensure that the sheet-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com