Irregularly-shaped reed shaping clamp for jet loom

A technology for setting fixtures and special-shaped reeds, which is applied in looms, textiles, textiles, and papermaking, etc. It can solve the problems of uneven pressure and uneven force, and achieve convenient clamping operations, avoiding rotation and shaking, and clamping mechanism The effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

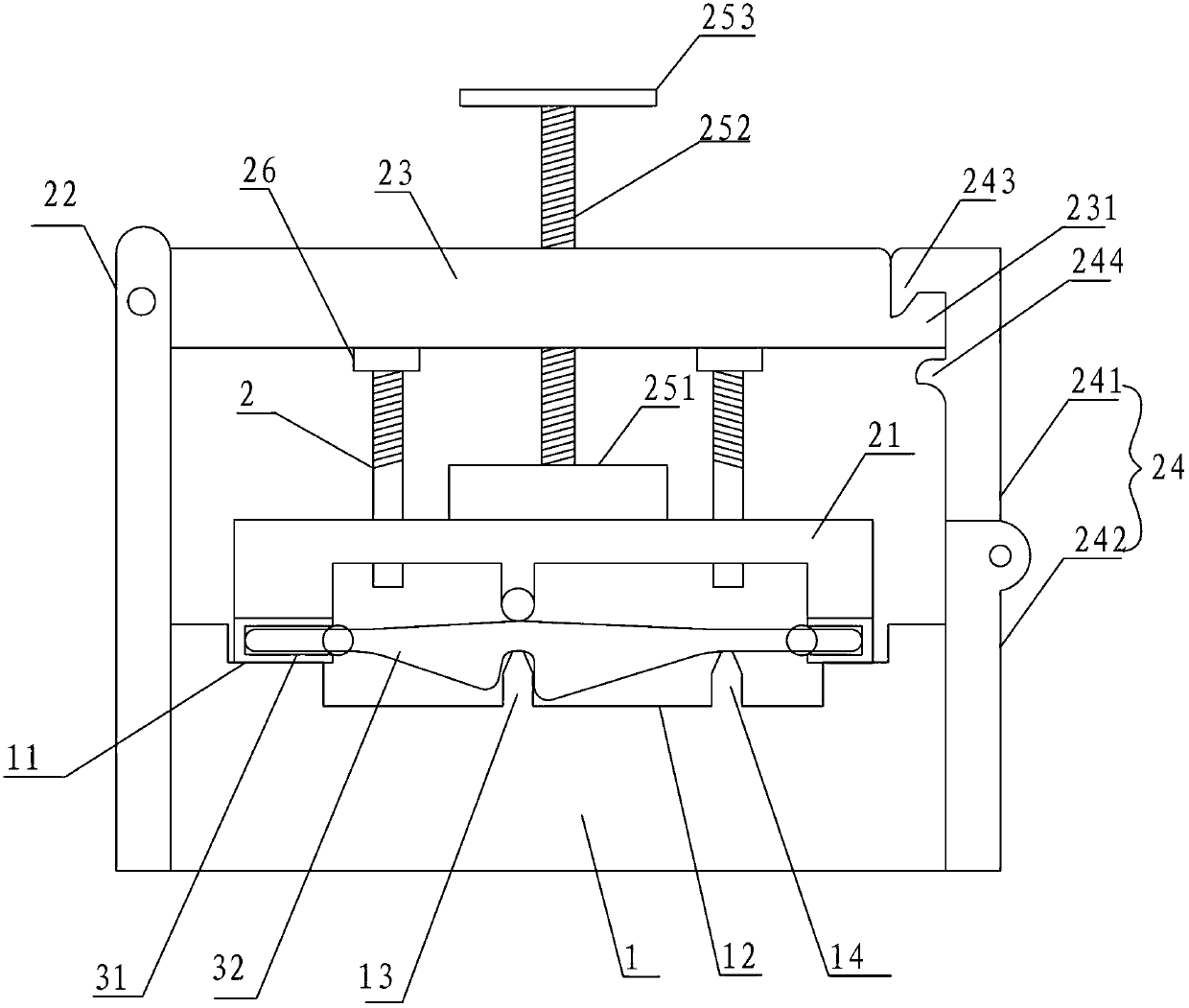

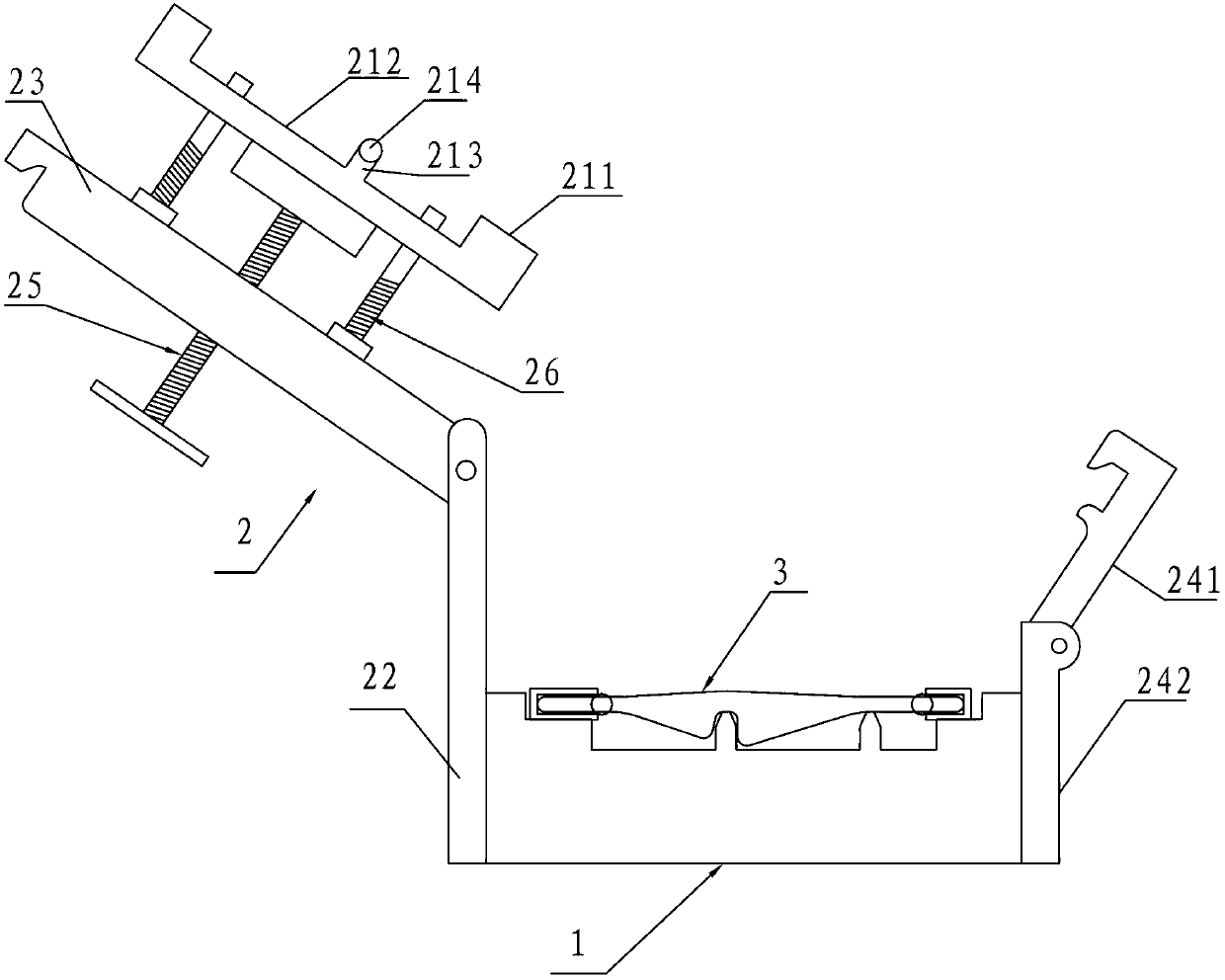

[0021] A profiled reed shaping fixture for an air-jet loom mainly includes a shaping fixture base 1 and a plurality of clamping mechanisms 2 . Shaping fixture base 1 is a pedestal body, can adopt the base in the traditional shaping fixture, and its longitudinal length will accommodate the steel reed 3 with shaping. The clamping mechanism 2 adopts multi-point distribution, that is to say, it can be arranged at multiple points according to the length of the reed 3 on a sizing fixture base 1, so as to realize the distributed multi-point force application in the clamping and sizing process.

[0022] The main components involved in the clamping mechanism 2 include a pressing plate 21 , a tension straight bar 22 , a crosspiece 23 , a tension hook bar 24 , a pressure bar 25 , and a positioning bar 26 .

[0023] The tension straight bar 22 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com