Thin steel sheet clamping and tensioning device and method for clamping and tensioning thin steel sheet

A technology of tensioning device and thin steel sheet, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of unsatisfactory laser precision processing technology, poor quality of cutting hole wall, increase of bumps and dross, etc. problems, to achieve uniform force, eliminate local wrinkling and deformation, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

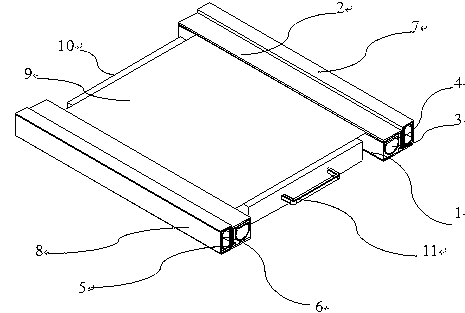

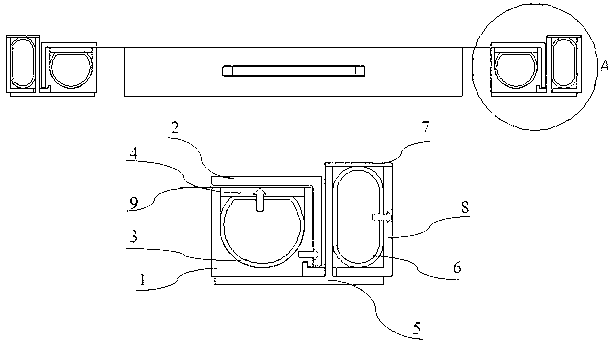

[0022] Such as Figure 1-2 As shown, a thin steel sheet clamping and tensioning device includes left and right clampers, and the right clamper includes a U-shaped airbag groove 1, an L-shaped movable clamping bar 2, a large airbag 3, and an upper top pressure Tight bar 4, T-shaped base 5, oblate small air bag 6, small cover plate 7 and hook-shaped tension bar 8; U-shaped air bag groove 1 is installed on the left side of T-shaped base 5, and U-shaped air bag groove 1 is provided with Large air bag 3, above the large air bag 3, in the U-shaped air bag groove 1 is provided with an upper top pressing bar 4, and at the right end of the U-shaped air bag groove 1 is provided with an L-shaped mobile clamping bar 2, and the L-shaped mobile clamping bar One end of 2 is close to the right end of U-shaped airbag groove 1, and the other end is above U-shaped airbag groove 1 and forms a slot with U-shaped airbag groove 1, and said slot is used to accommodate thin steel sheet 9; The right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com