Tin body suction type water draining device for canning water control machine

The technology of a tank body and a water machine is applied in the field of the tank body suction, extraction and drainage device, which can solve the problems of inability to automate continuous production, and achieve the effects of saving labor costs, complete control, and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

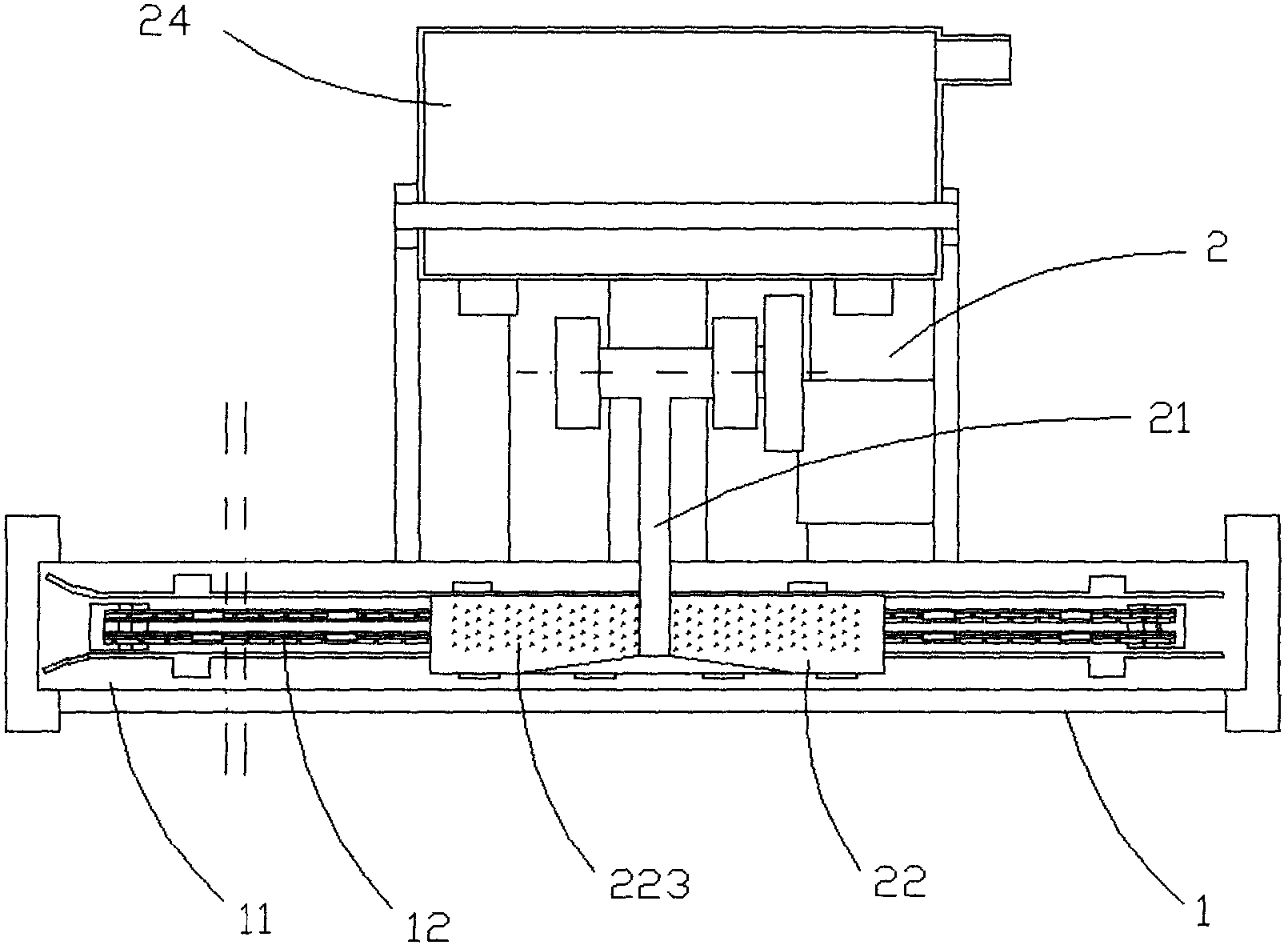

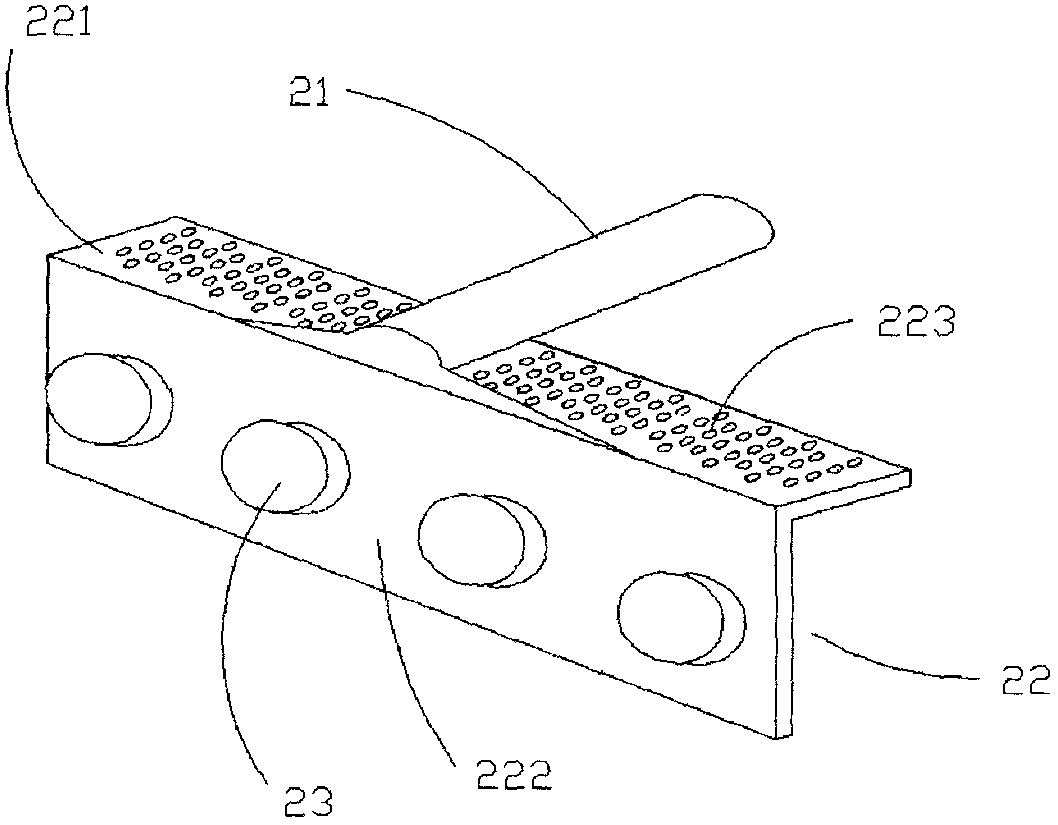

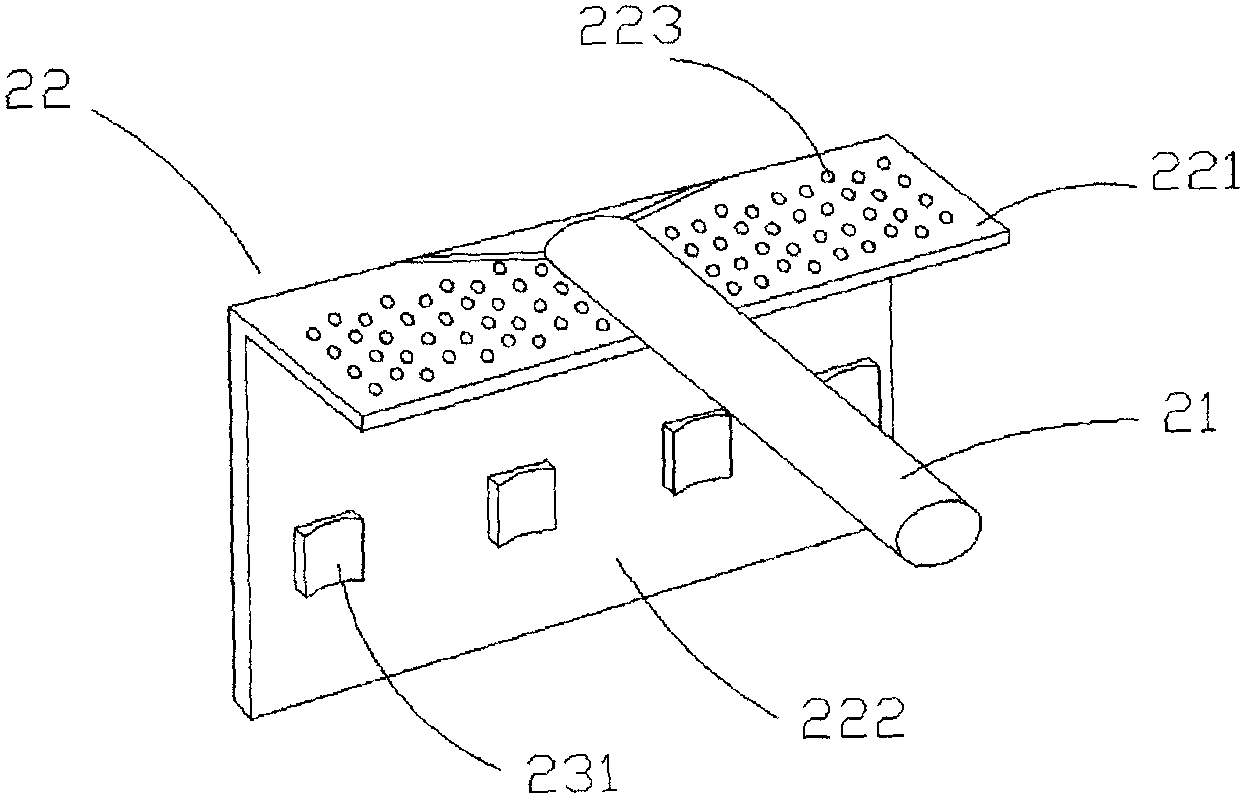

[0023] Such as Figure 1-4 As shown, a tank body suction and draining device of a tank water control machine includes a tank conveying mechanism 1, a draining mechanism 2 and a controller. There is a conveying chain 12, and the conveying chain 12 is provided with evenly arranged push claws 121, the distance between the push claws and the push claws is greater than the sum of the diameters of the two cans, and the two sides of the conveying chain 12 are provided with can retaining rods 13. The two ends of the support seat 11 can be connected to the supporting production equipment of the next process. The two ends of the rotating shaft 26 of the rotating swing arm 21 of the draining mechanism 2 are connected to the rotating shaft seat 27, and the rotating swing arm 21 and the conveying chain 12 rotate under the transmission of the driving mechanism. The top of the rotating swing arm 21 is connected with a can suction device 22 parallel to the conveying chain 12. The can suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com