Auxiliary pushing mechanism for die scrap discharge

A material pushing mechanism and waste material technology, which is applied in the direction of forming tools, manufacturing tools, and pushing equipment, etc., can solve the problems of waste material card slot accumulation, etc., and achieve the effect of reducing manufacturing costs, good effect, and reducing the minimum included angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Attached below figure 1 to attach image 3 , the present invention is further described:

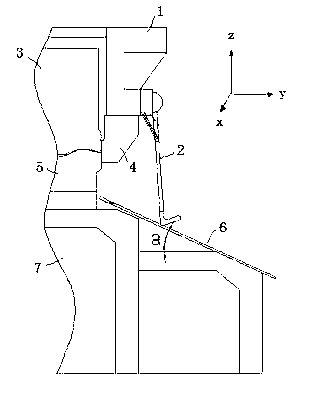

[0024] figure 1 It shows an assembly diagram of an auxiliary pushing mechanism for ejecting mold waste. The auxiliary pushing mechanism 2 is arranged on the upper mold body 1 and is located on the side where the mold produces waste, that is, the pressing core 3 and the upper mold trimming knife block 4 and the right side of lower die trimming cutter block 5, and above the waste slide plate 6, the waste slide plate 6 is at an angle with the press workbench that is arranged on the lower die body 7.

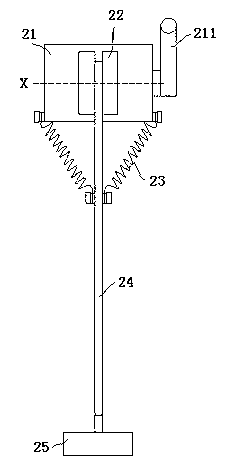

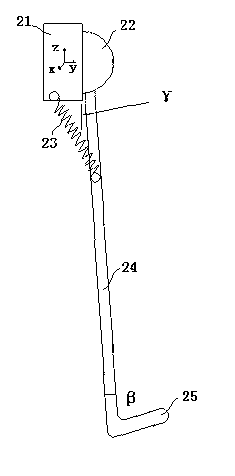

[0025] figure 2 and image 3 Shown is the schematic structural view of the auxiliary pushing mechanism, and the auxiliary pushing mechanism 2 includes a fixing device, a hinge 22, a resetting device, a connecting rod 24 and a pushing plate 25; among the present invention, the fixing device is a permanent magnet sucker 21, and the resetting device is a spring 23; the upper end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com