Dry land pot seedling ejection dropping mechanism

A technology of ejecting mechanism and seedling falling, which is applied in the field of agricultural machinery, can solve the problems of low planting speed, high labor intensity, time-consuming feeding, etc., and achieve the effects of simplified machine tool structure, high degree of automation, and good uprightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

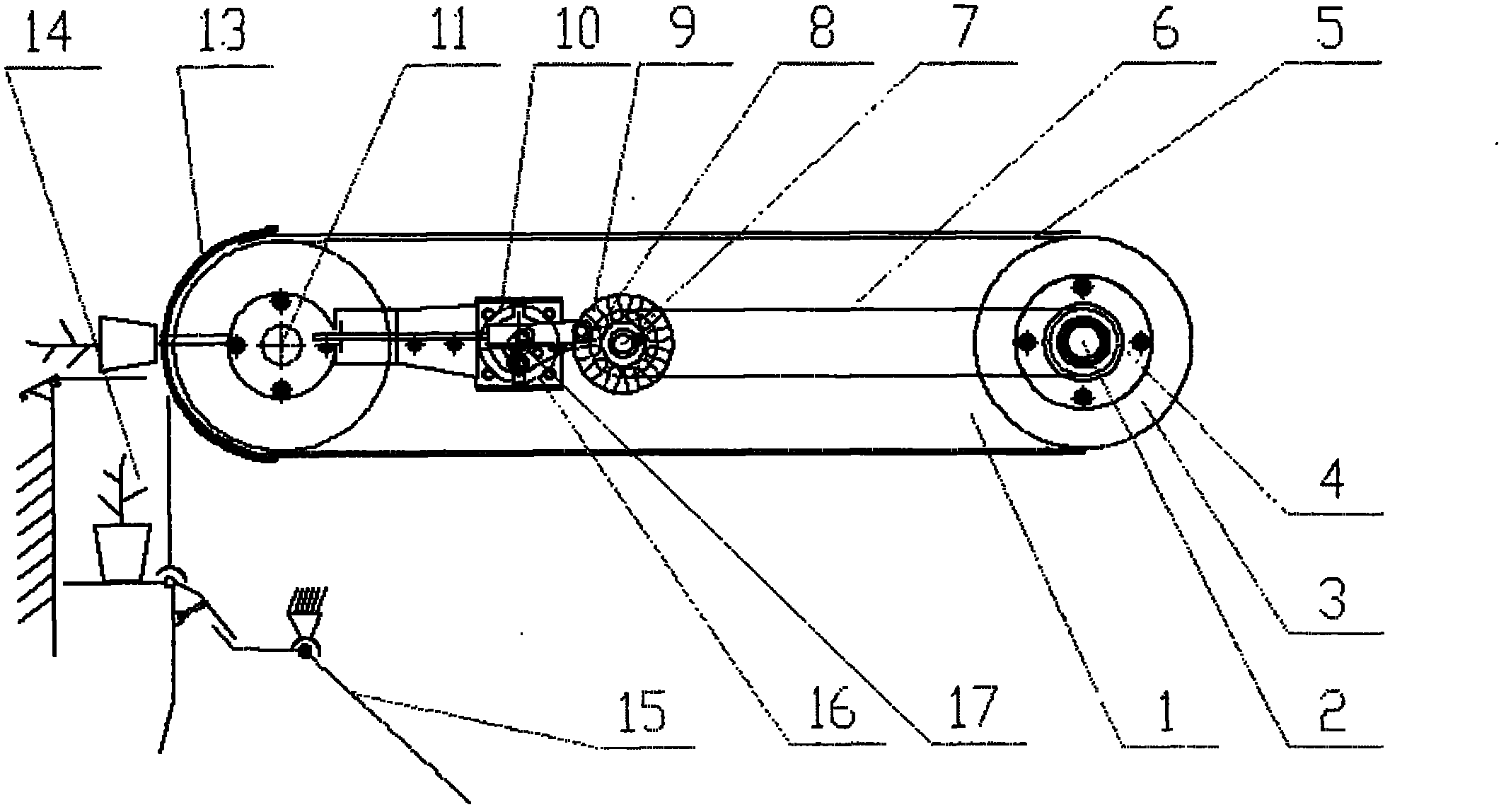

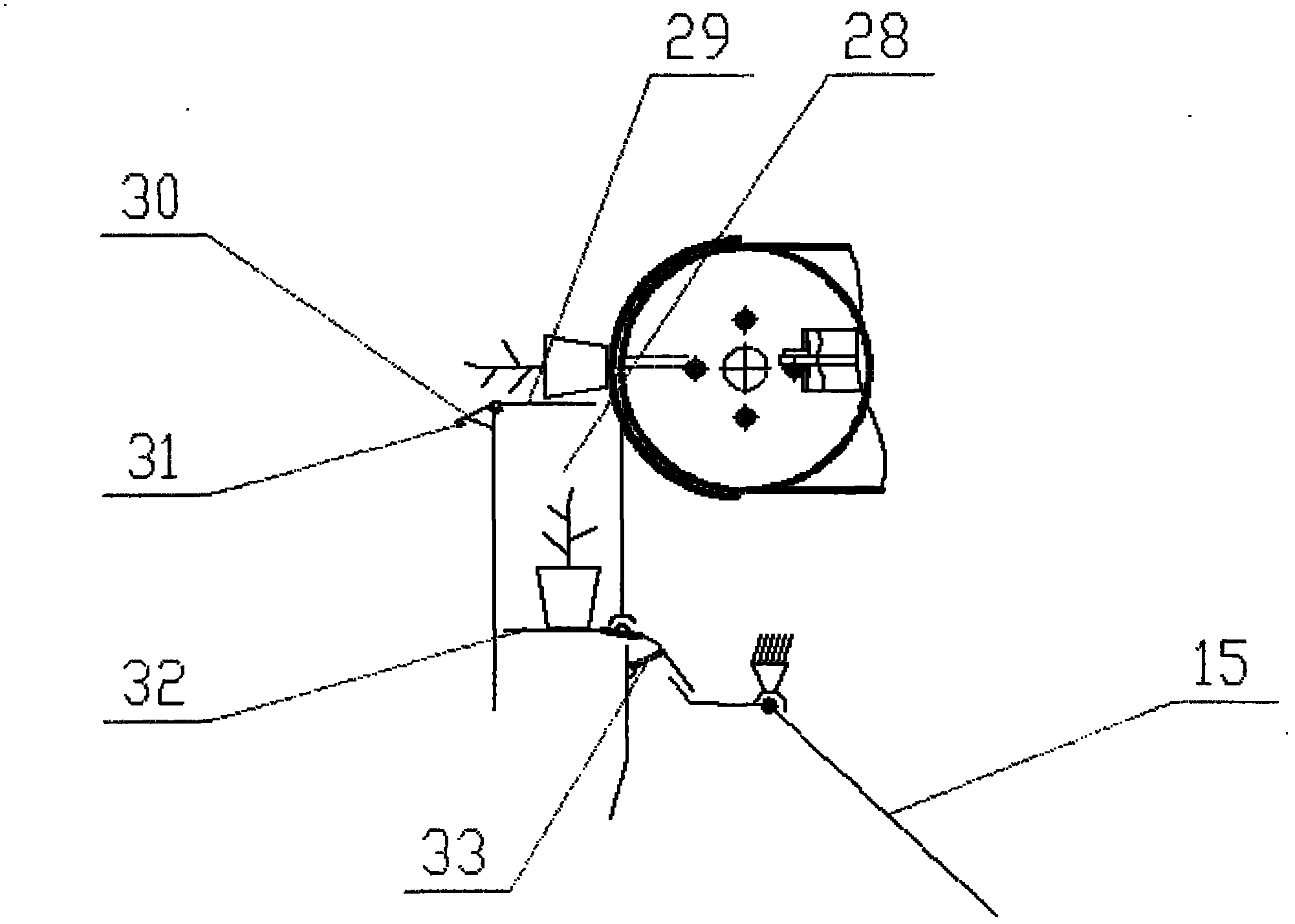

[0010] The creative implementation scheme of the present invention will be further described below in conjunction with the drawings. A dry field pot seedling ejecting and falling seedling mechanism, the power input sprocket 16 is installed on the ejecting small shaft 17, the ejecting mechanism assembly 10 is installed on the position between the two oppositely arranged pot tray side arm support plates 1, Install the drive shaft 2 on the rear side of the two pot side arm support plates 1, and fix the seedling feeding sprocket 3 and the driven small sprocket 4 on the drive shaft 2 on the rear side of the ejector assembly 10 An intermittent shaft 7 is installed on the side arm support plate 1 of the pot plate. The intermittent disk 9 and the driving small sprocket 8 are fixed on the intermittent shaft 7, and the driving small sprocket 8 and the driven small sprocket 4 are equipped with a transmission chain 6 , Install the rotating small shaft 11 on the front side of the two pot si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com