Device for fixing clutch slave cylinder

A clutch wheel pump and fixing device technology, applied in the field of machinery, can solve problems such as increased production cost, waste of resources, etc., and achieve the effects of enhancing applicability, reducing weight, and improving the installation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

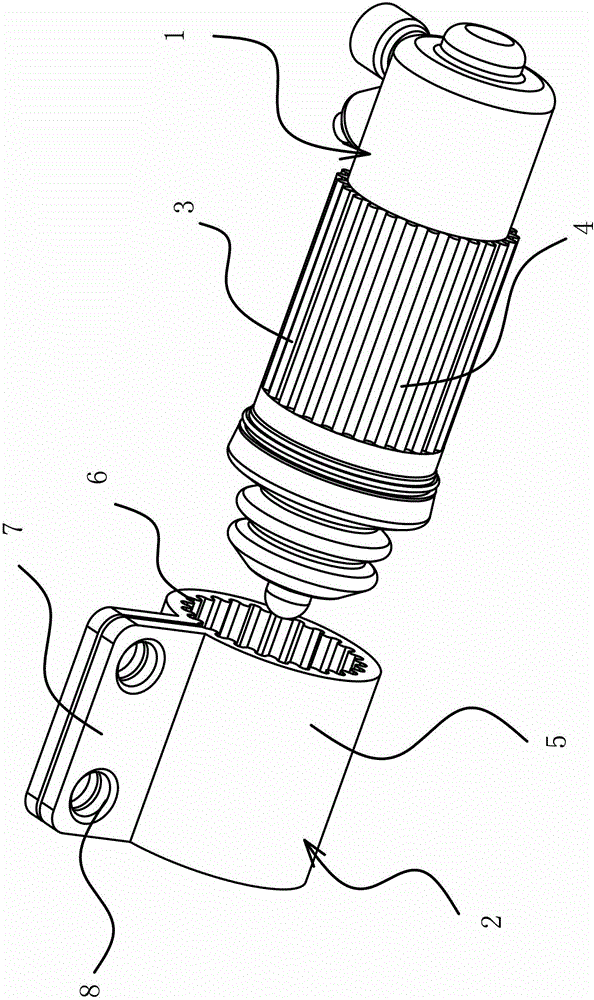

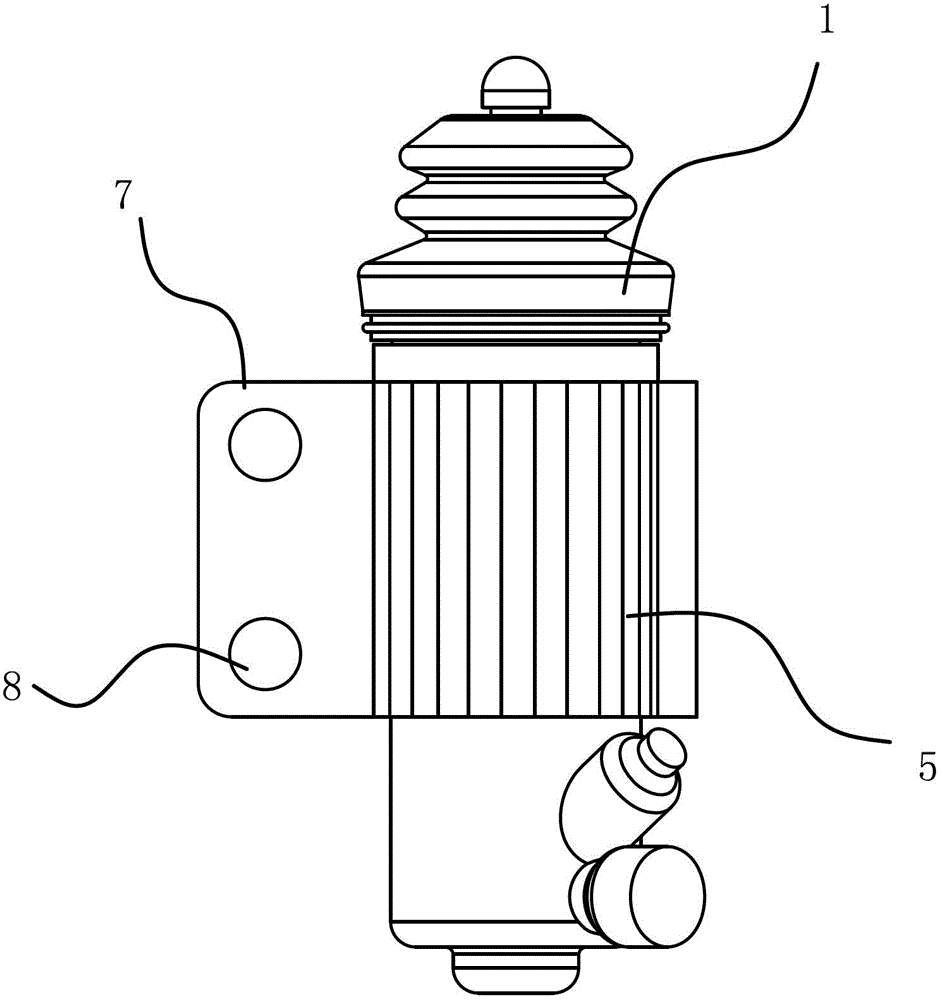

[0027] Such as figure 1 , figure 2 , image 3 As shown, the clutch slave cylinder can be connected to the transmission housing through the fixing device, and the clutch slave cylinder has a pump body 1 . The fixing device of the clutch slave cylinder includes a cylindrical connection part 3 on the clutch slave cylinder pump body 1 and a mounting flange 2 for fixing the pump body 1 on the transmission case. The mounting flange 2 has a positioning cylinder 5 nested with the connecting portion 3 of the pump body 1 , and a positioning mechanism capable of fixing the pump body 1 both circumferentially and axially is provided between the positioning cylinder 5 and the connecting portion 3 .

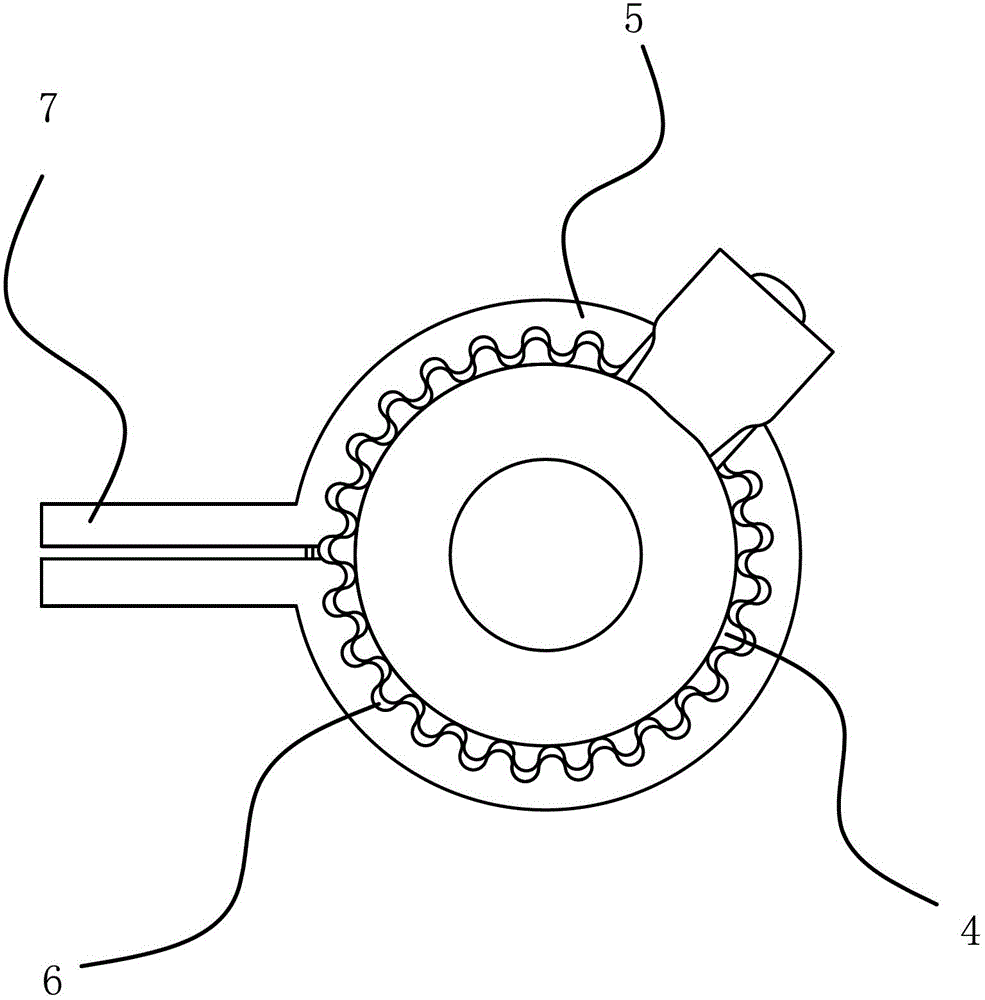

[0028] Specifically, the positioning mechanism includes a number of racks 4 circumferentially distributed on the connecting portion 3 and a number of tooth grooves 6 distributed on the inner surface of the positioning cylinder 5 and corresponding to the number of the racks 4 . When the conne...

Embodiment 2

[0032] Embodiment 2 is basically similar in structure to Embodiment 1, the difference lies in the positioning mechanism. Such as Figure 4 , Figure 5 As shown, the positioning mechanism of Embodiment 2 includes positioning pins 9, several through holes 10 provided in the circumferential direction of the positioning cylinder 5, and positioning grooves 11 provided on the connecting portion 3 of the pump body 1. When the positioning cylinder 5 is sleeved on the connecting portion 3, rotate the connecting part 3 to align the corresponding positioning groove 11 with the through hole 10 and fix the positioning cylinder 5 to the pump body 1 by inserting the positioning pin 9. The number of positioning pins 9, through holes 10 and positioning grooves 11 can be configured according to the actual installation conditions. If the mounting flange 2 needs to be replaced, the pump body 1 can be separated from the mounting flange 2 by pulling out the positioning pins 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com