Anti-silting drainage body device and method thereof

A drainage body and anti-sedimentation technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of reducing the drainage speed and hindering the contact between the drainage body and the external silt, and achieves convenient installation, disassembly and maintenance, simple structure, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

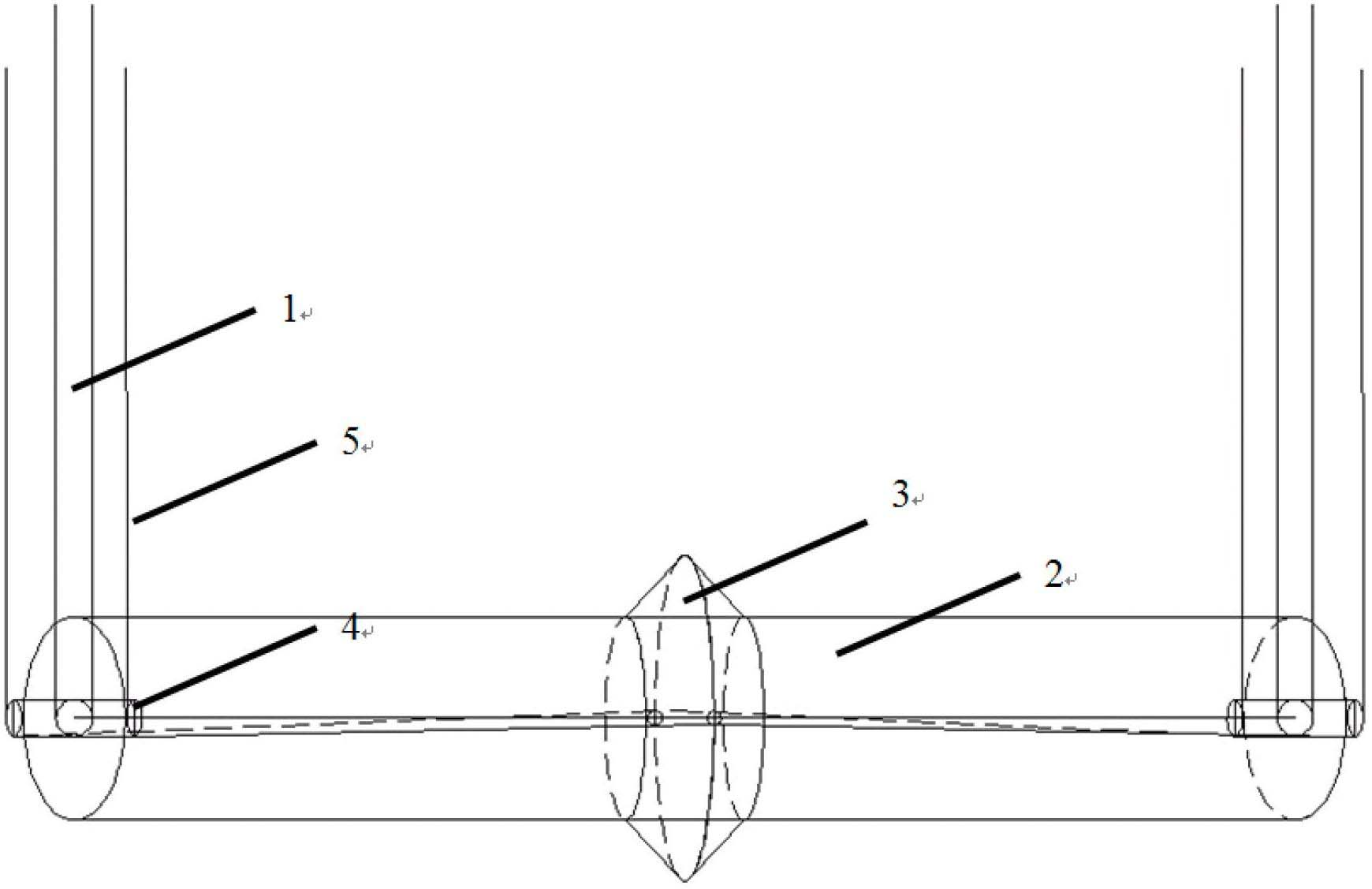

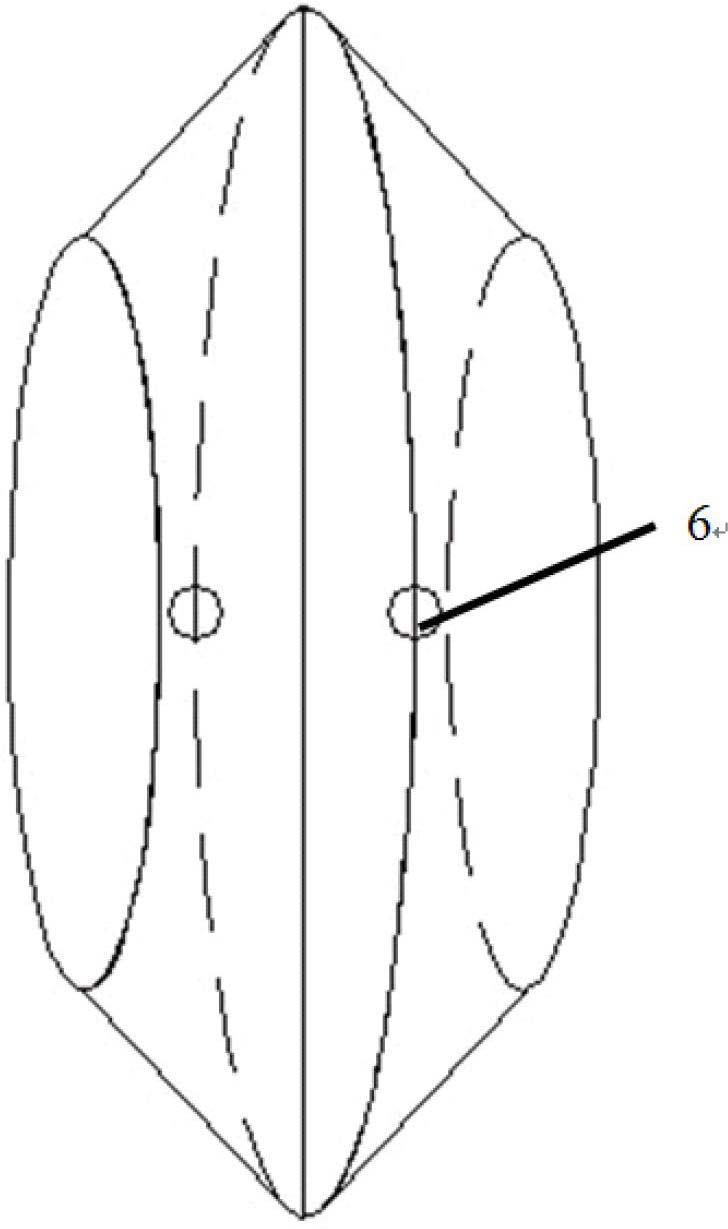

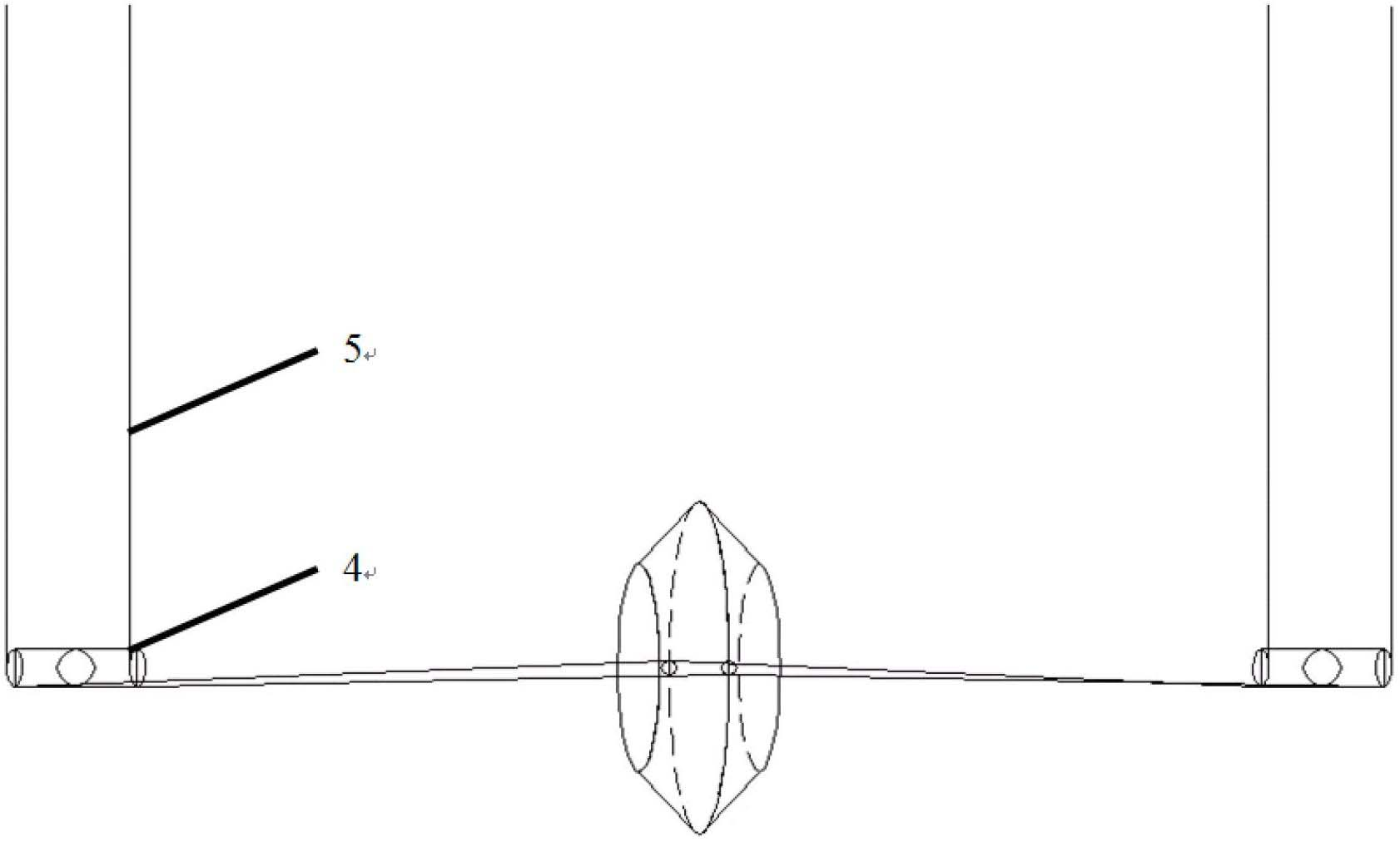

[0019] Such as Figure 1 to Figure 4 As shown, a kind of anti-silting drainage body device of the present invention comprises a cylindrical drainage body system, a reciprocating cone 3 and a reciprocating noose system, and the cylindrical drainage body system includes a frame-type cylindrical drainage body 2 and a hard Vacuum pipe support 1, the two ends of the cylindrical drainage body 2 are respectively connected to a hard vacuum pipe support 1, the outer wall of the cylindrical drainage body 2 is wrapped with a filter material layer, and the inside of the cylindrical drainage body 2 is covered with a plastic blind ditch As a support, both ends of the cylindrical drainage body 2 are sealed and connected to the joint of the hard vacuum pipe support 1; the reciprocating cone 3 connects the lower bottom surfaces of two identical frustum bodies, and the overall shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com