Steel wire cerclage fixing device

A fixation device and wire ring technology, applied in fixers, medical science, surgery, etc., can solve problems such as lack of fit, and achieve the effects of reduced secondary damage, convenient cleaning, and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

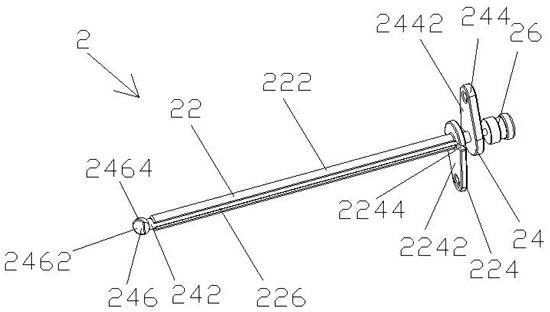

[0049] See Figure 1 to Figure 9 , A steel wire circling fixing device, comprising a first steel wire guiding device 1, a second steel wire guiding device 2, a steel wire tightening and breaking device 3.

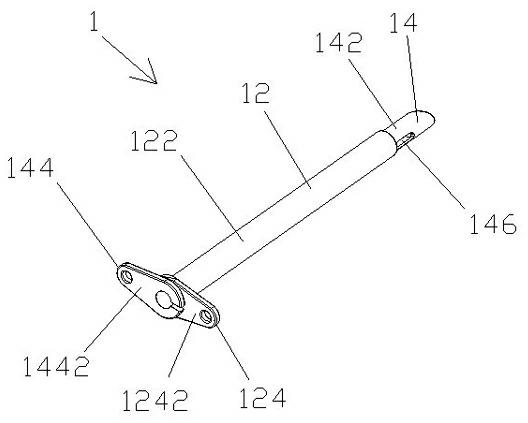

[0050] The first wire guiding device 1 includes a first sleeve 12 and a first lance 14.

[0051] The first sleeve 12 includes a cylindrical first outer cylinder 122 and a first sleeve handle 124 provided at the rear end of the first outer cylinder 122.

[0052] The first sleeve handle 124 includes a first sleeve handle extension piece 1242 perpendicular to the first outer cylinder 122.

[0053] The first outer cylinder 122 and the first sleeve handle 124 are provided with a linear first outer cylinder opening 126 parallel to the central axis.

[0054] The first outer cylinder opening 126 penetrates the first sleeve handle 124, and a first sleeve handle opening 1244 is formed at the first sleeve handle 124.

[0055] The first lancet 14 includes a cylindrical first inner barrel 142 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com