Small self-propelled alfalfa cradling and flattening machine

A self-propelled, flattening machine technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of large size, poor flexibility and inadaptability, and achieve small moving range, wide applicability, and improved work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

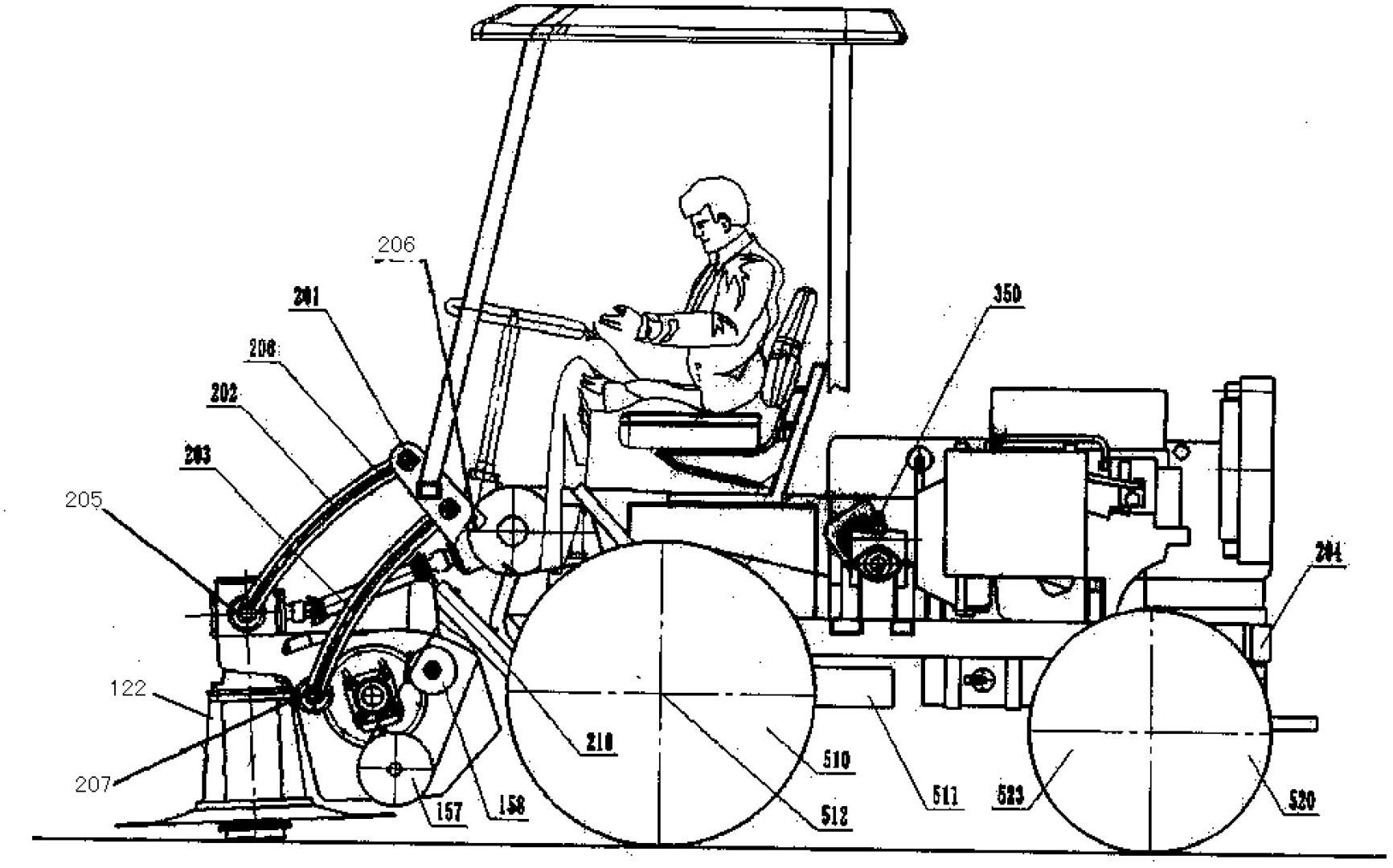

[0030] Such as figure 1 As shown, the front axle device 510 is responsible for driving the machine forward and backward, and the front axle 512 is driven by the drive motor 511 to realize stepless speed regulation. Rear axle device 520 is responsible for steering, and one end of steering oil cylinder 523 is pinned with rear axle 521, and the other end is pinned with rear axle tie rod 522, realizes the adjustment of turning size by controlling the expansion and contraction of steering oil cylinder 523.

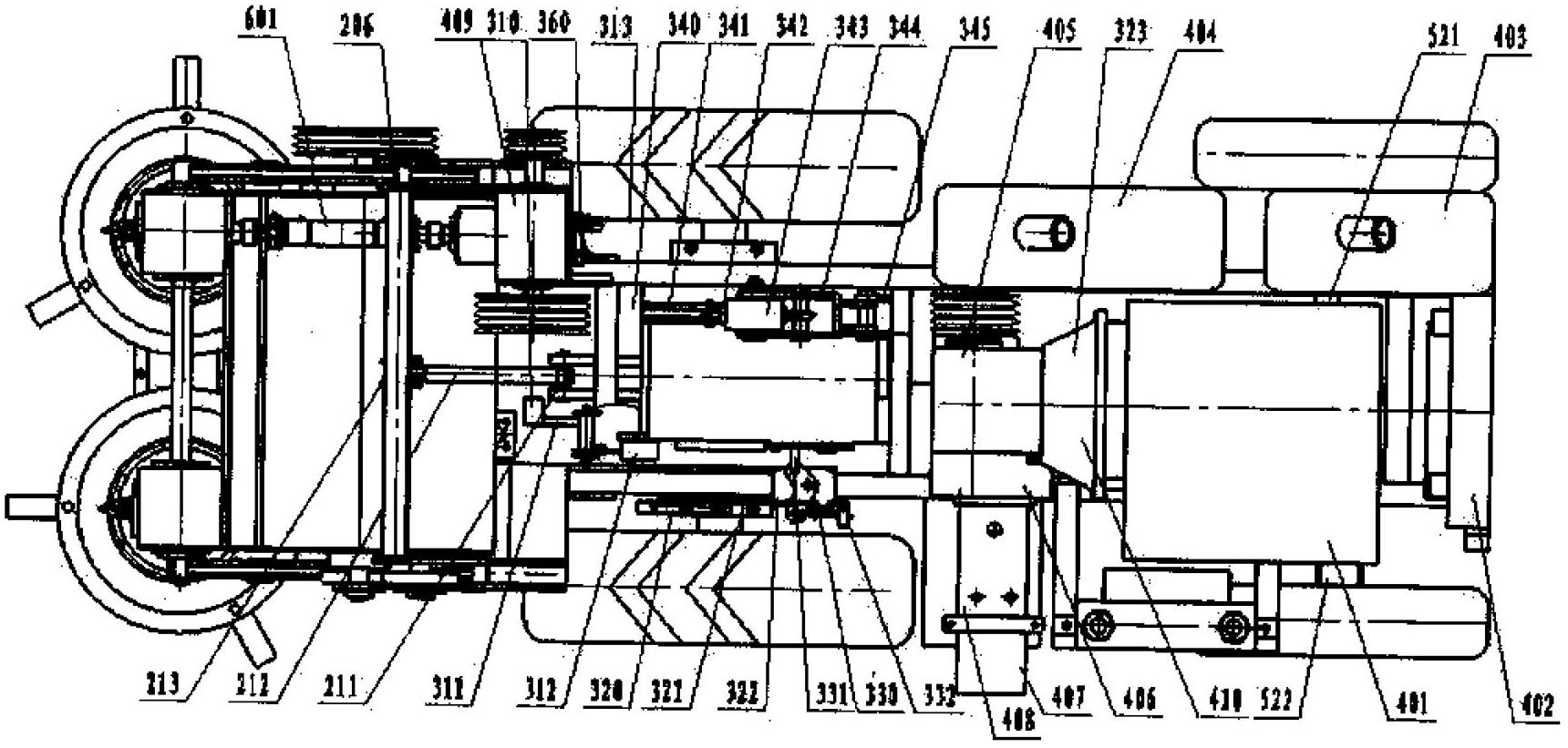

[0031] Such as figure 2 The power of the whole machine shown is output by the engine 401, which is transmitted to the hydraulic oil pump gearbox 406 through two spur gears through the transfer case 410, and to the steering gearbox 409 through the gang belt, and the hydraulic oil pump gearbox 406 outputs the power to the main pump 408 and tail pump 407, the main pump 408 transmits power to the drive motor 511 to drive the machine forward, and the steering gear box 409 outputs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com