Pipe handling system and method for handling pipe

A technology for pipe fittings and supply systems, applied in the directions of pipe laying and maintenance, pipe/pipe joints/pipe fittings, drilling pipes, etc., can solve the problem of large size of the arm, and achieve the effect of increased safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

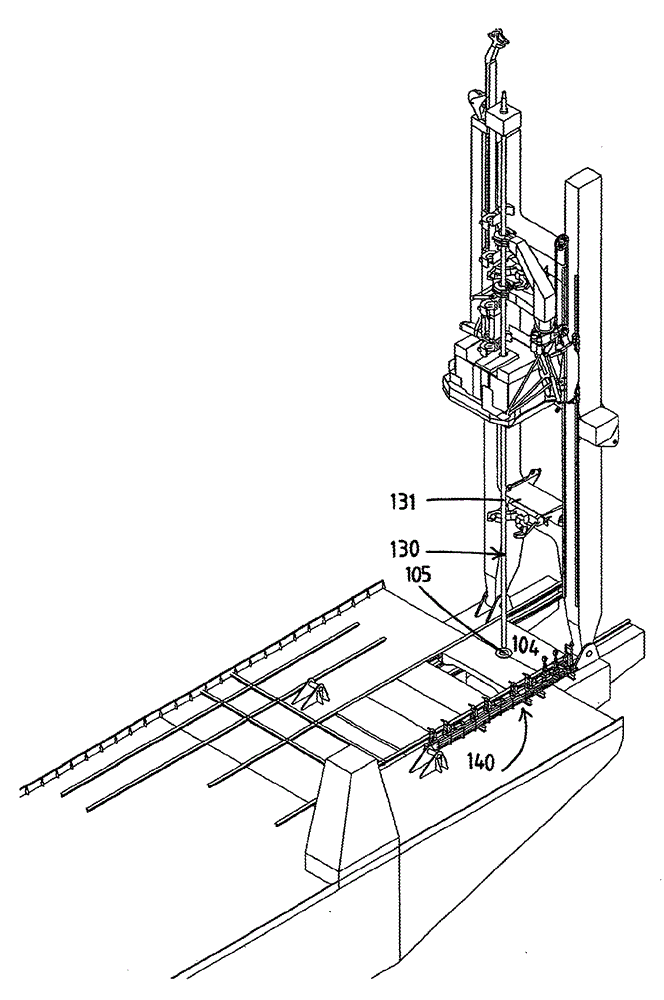

[0038] exist figure 1 In , a pipe handling system 1 according to the invention is shown. The pipe handling system 1 includes a stand 20 for supporting the tower 10 . Column 10 is in this embodiment a line delivery column 10, which will be described in more detail below. Tower 10 allows pipelines (and other objects as will be explained) to be dropped through a moon pool (not shown) or alongside stand 20 .

[0039] Here, the tower is positioned on the end side of the support 20 , for example possibly on the stern side of the ship. In alternative arrangements, the tower 10 may be arranged, for example, on the port side of the ship or on the starboard side of the ship, or in the mid-section of the ship.

[0040] In another not shown embodiment, the tower may be in the form of a derrick (eg a lattice frame) extending over the moonpool, with a working line or tubular launching track passing within the derrick structure.

[0041]The lower end of the tower 10 is supported on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com