Internal and external wire-winding type motor stator wire-winding device, wire-winding control method and winding method

A technology of motor stator and winding device, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of high error rate, cumbersome operation, late start, etc., and achieve the effect of high efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with accompanying drawing:

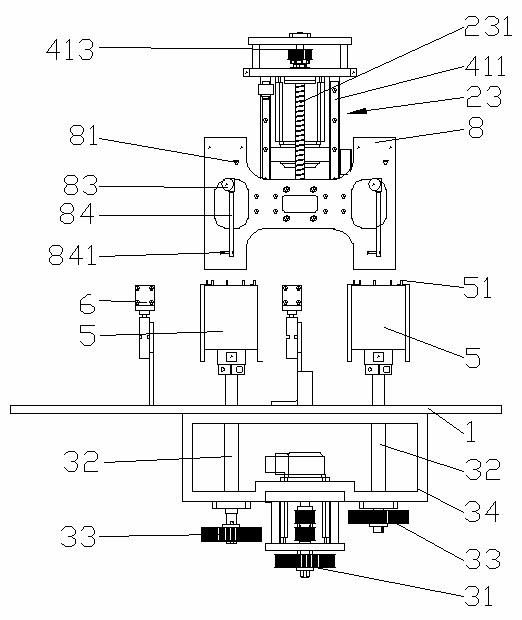

[0043] see figure 1 As shown, the inner and outer winding motor stator winding device includes: chassis 1, a position shifting mechanism and a cage winding mechanism arranged on the chassis 1, a support arm 4 capable of three-dimensional movement carried on the position shifting mechanism, and a support arm 4 arranged on the support arm 4. There is a winding drive mechanism, and an electric control module (not shown in the figure) is provided in the control cabinet under the chassis 1; the whole machine is also equipped with power equipment and synchronous rotation that provides power for the position moving mechanism and the cage winding mechanism Institution 3.

[0044] The position moving mechanism is composed of an X-axis moving assembly 21 , a Y-axis moving assembly 22 and a Z-axis moving assembly 23 for the support arm 4 to perform three-dimensional movemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com