Fully-mechanized excavating self-moving type temporary support system and technological method thereof

A temporary support and self-moving technology, which is applied in the field of automation, centralization, and large-scale fully mechanized mining technology in coal mines, can solve the problem of slow bolt support, limitation of driving speed, and restrictions on the ability of fully mechanized excavation equipment. It can improve the speed of fully mechanized excavation, exert its efficiency, and shorten the impact time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

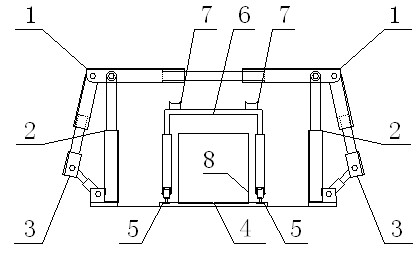

[0018] Bottom-laying self-moving temporary support system The self-moving temporary support system for fully-mechanized excavation where the moving track is arranged in sections on the roadway floor. The temporary support equipment mainly includes: temporary supports, moving tracks and moving vehicles. This method can be used for excavation of large section. The technological characteristics of the self-moving temporary support system are ( figure 1 ):

[0019] 1). Use fully-mechanized excavator 8 to excavate the coal wall or rock wall, and at the same time use fully-mechanized excavator 8 and belt conveyor to transport coal and rock, stop after excavating 3.0m, and clean the excavation site for 3 minutes

[0020] 2). Lay the moving track support 4 and the moving track 5, hang the net on the coal wall (or rock wall) and the roof, then expand the temporary support top beam 1, raise the temporary support pillar 2, and prop up the temporary support leg 3 , the temporary support...

Embodiment approach 2

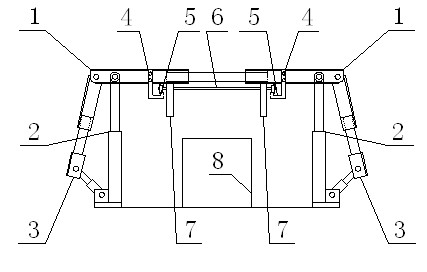

[0026] Hanging self-moving temporary support system The moving frame track is suspended in sections under the top beam of the roadway temporary support and the self-moving temporary support system. The temporary support equipment mainly includes: temporary support, moving track and Move the car. This method can be used for small section excavation. The main difference between the self-moving temporary support system and the first method is that the moving track is suspended, and its technological characteristics are ( figure 2 ):

[0027] 1). Use fully-mechanized excavator 8 to excavate the coal wall or rock wall, and at the same time use fully-mechanized excavator 8 and belt conveyor to transport coal and rock, stop after excavating 0.8m, and clean the excavation site for 1 minute

[0028] 2). Install the shifting track frame and shifting track on the temporary support, hang the net on the coal wall (or rock wall) and the roof, then unfold the temporary support top beam 1,...

Embodiment approach 3

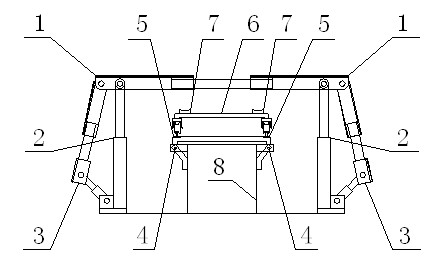

[0034] Frame semi-fixed self-moving temporary support system, the moving frame track is fixed on the roadheader and transporter through the track frame, and the temporary support equipment mainly includes: temporary support, moving frame track And moving truck, this method can be used for large, medium and small section excavation. The main difference between this self-moving temporary support system and Embodiment 1 and Embodiment 2 is that the frame-moving track is semi-fixed, and the frame-moving track does not need to be laid and installed, but needs to be dragged (such as image 3 ), its technological features are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com