Experimental simulation method for hydrate production and confining pressure loading and thermal insulation integrated system

A liquid and hydraulic press technology, applied in the field of natural gas hydrate research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

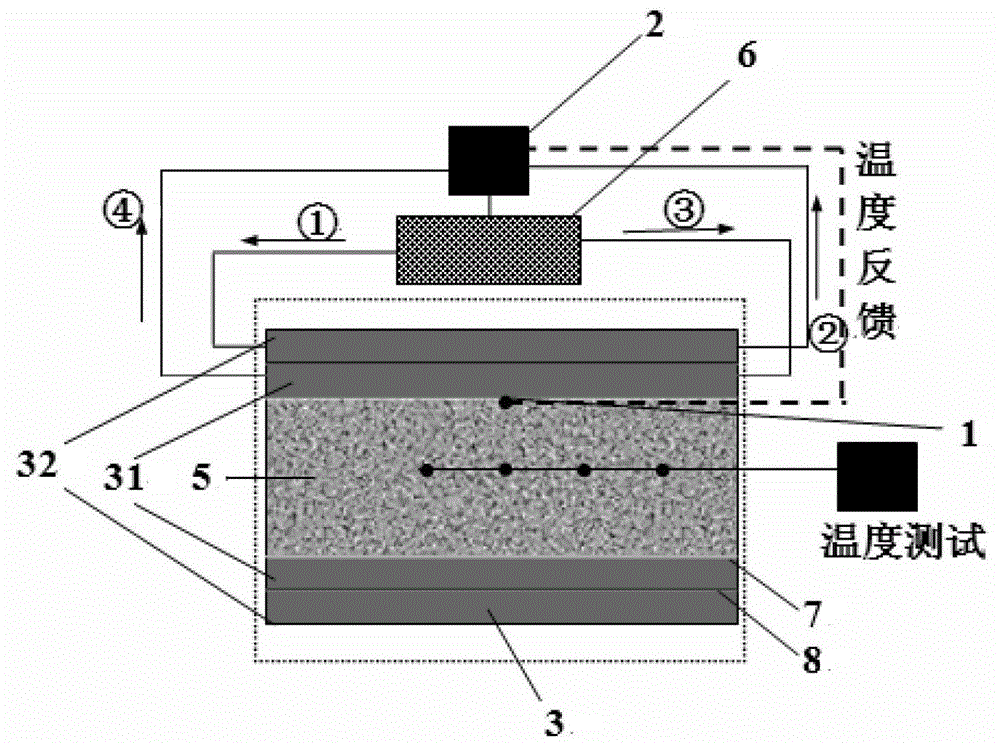

[0032] Hereinafter, the embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other arbitrarily if there is no conflict.

[0033] The system of the present invention has a heat insulation (temperature control) function and a confining pressure loading function.

[0034] During the hydrate decomposition process, the temperature of the hydrate deposition layer in the pressure chamber of the hydrate mining simulation experimental device changes due to the heat absorption of hydrate decomposition. In order to avoid heat exchange between the hydrate deposition layer and the outside world, a high-precision temperature sensor can be placed in the hydrate deposition layer (the accuracy of the temperature sensor is less than or equal to 0.01℃) to test the temperature of the deposition layer during the hydrate decompo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com