Lifting device for rolling brush of small electric sweeper

A lifting device and cleaning vehicle technology, applied in road cleaning, cleaning methods, construction, etc., can solve problems such as difficulty in ensuring uniform axial contact pressure of rolling brushes, low positioning stability of rolling brushes, large volume and quality, etc. To achieve the effect of compact structure, balanced contact pressure and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

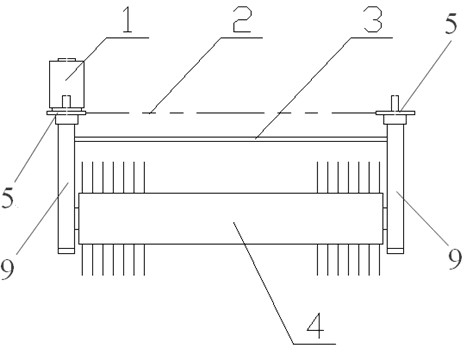

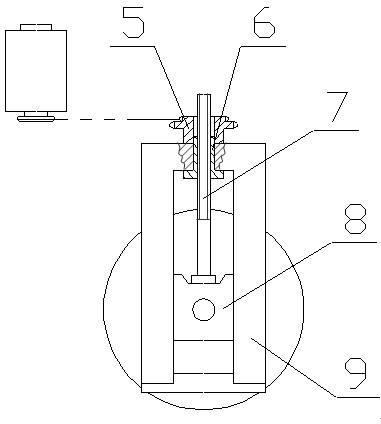

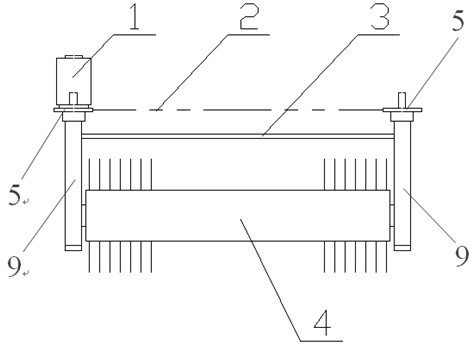

[0016] Such as figure 1 , 2 As shown, the lifting device of the small-sized electric sweeper roller brush of the present invention includes a bracket 3, a sprocket 5, a nut 6, a chain 2 arranged between the sprockets 5, a DC motor 1 connected to the sprocket 5, and a chain The screw mandrel 7 that wheel 5 links to each other with nut 6 and the bearing housing 8 that links to each other with screw mandrel 7, the two ends of support 3 are provided with guide rail 9, and bearing housing 8 is located in the middle of guide rail 9 at both ends. The sprocket 5, the nut 6 and the screw mandrel 7 are adapted to form a screw transmission mechanism, and the screw mandrel 7 drives the bearing seat 8 and the roller brush 4 connected to the bearing seat 8 to perform vertical lifting work.

[0017] The working process of the lifting device of the roller brush of the small electric cleaning vehicle of the present invention is as follows: a DC motor 1 is used as the driving source, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com