Device for necking grooved self-locking nut

A technology of self-locking nuts and closing devices, which is applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of difficult closing processing, etc., and achieve the effect of improving performance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

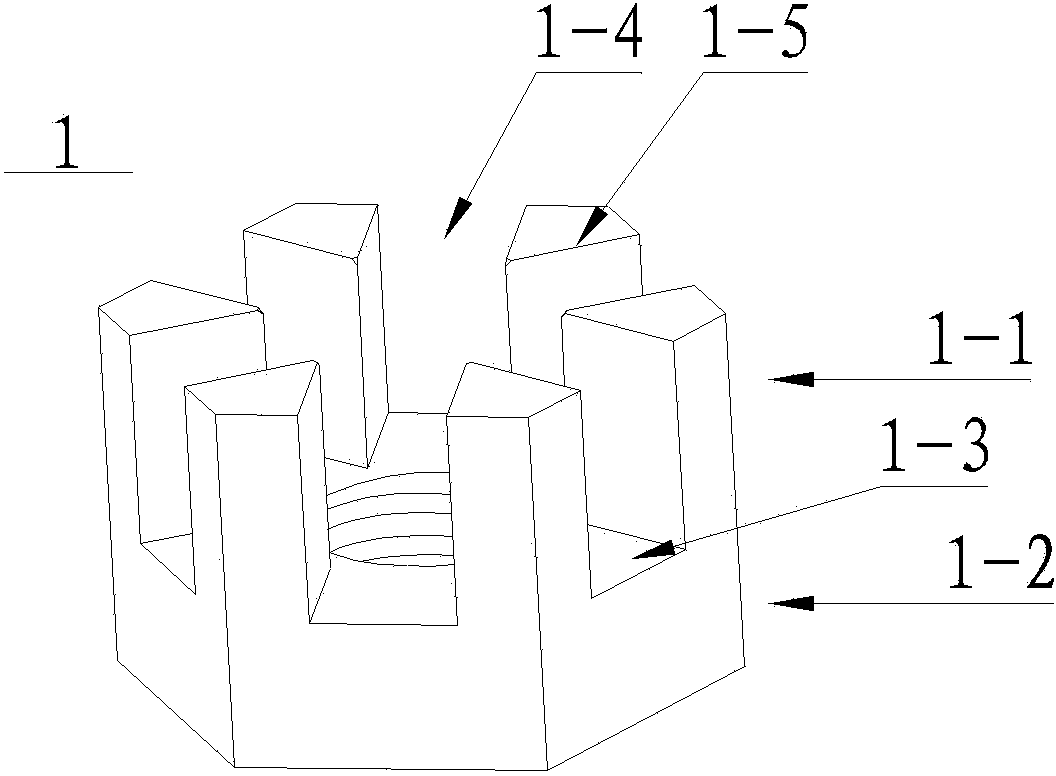

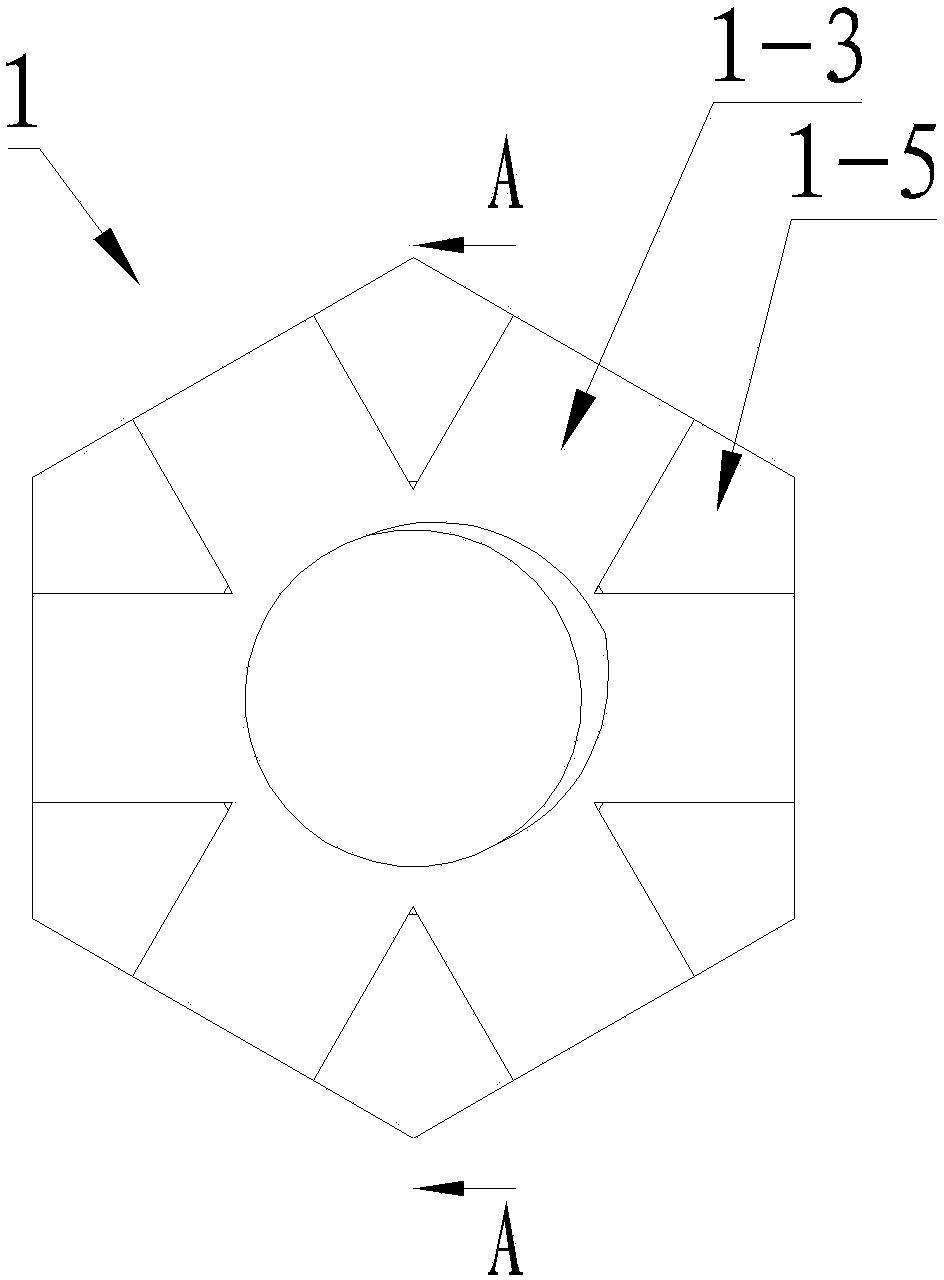

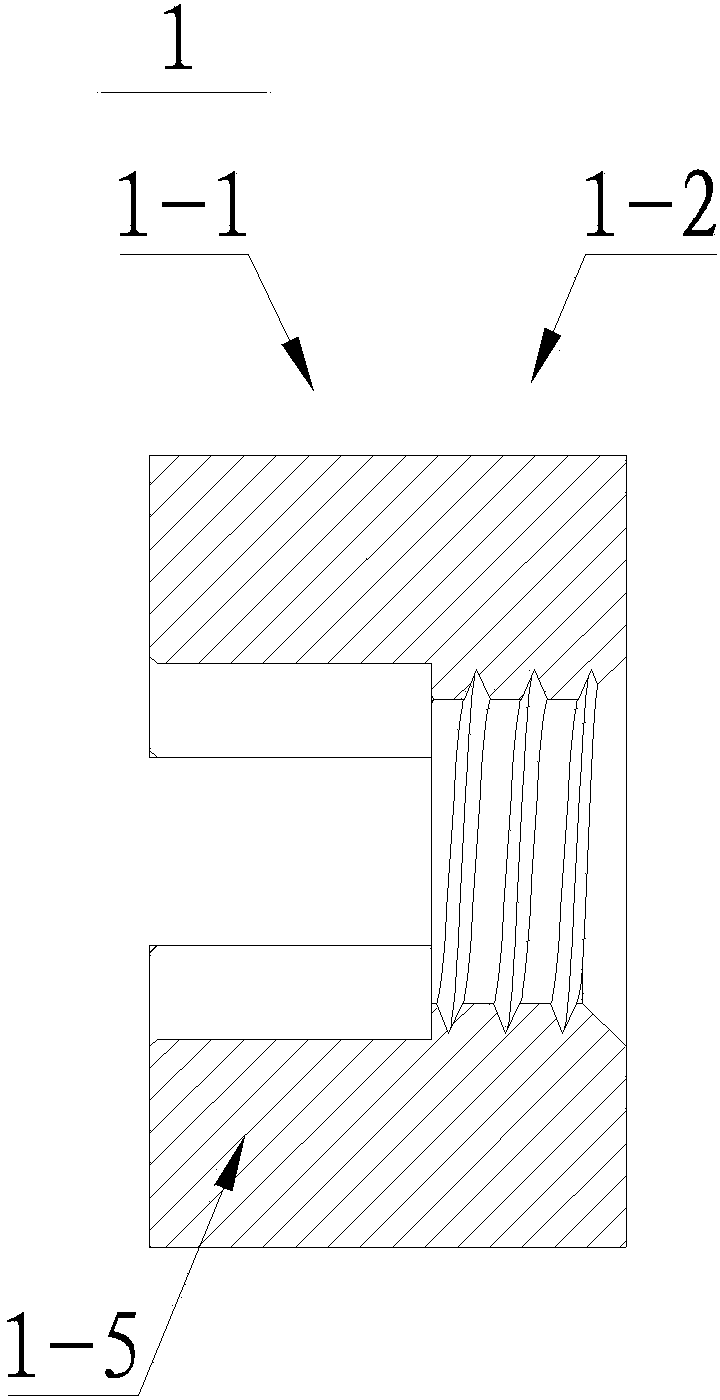

[0018] Embodiment of the closing device of the slotted self-locking nut of the present invention: as Figure 1 to Figure 7 As shown, the closing device is composed of a columnar body 2 and three pressure claws 3 uniformly protruding from the outer circumference of the columnar body 1, wherein the columnar body 2 is a cylinder; 1 between the notch end 1-1 and the connecting end 1-2, the extruding end 3-1 exerts the extruding force on the annular groove bottom surface 1-3, and the end face and the side of the extruding end 3-1 pass through The circular chamfered surface processed between the two sides transitions, and the diameter of the smallest inscribed circle at the bottom of the circular chamfered surface of the extrusion end 3-1 of the three pressing jaws 3 is greater than that of the slotted self-locking nut workpiece 1 The inside diameter of the threaded hole at connection end 1-2.

[0019] When the present invention is in use, the columnar main body 2 is first installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com