Device having a plug-in connection

A technology of plug connection and driving side, which is applied in the direction of rigid shaft coupling, elastic coupling, friction clutch, etc., and can solve the problems of tooth tolerance and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

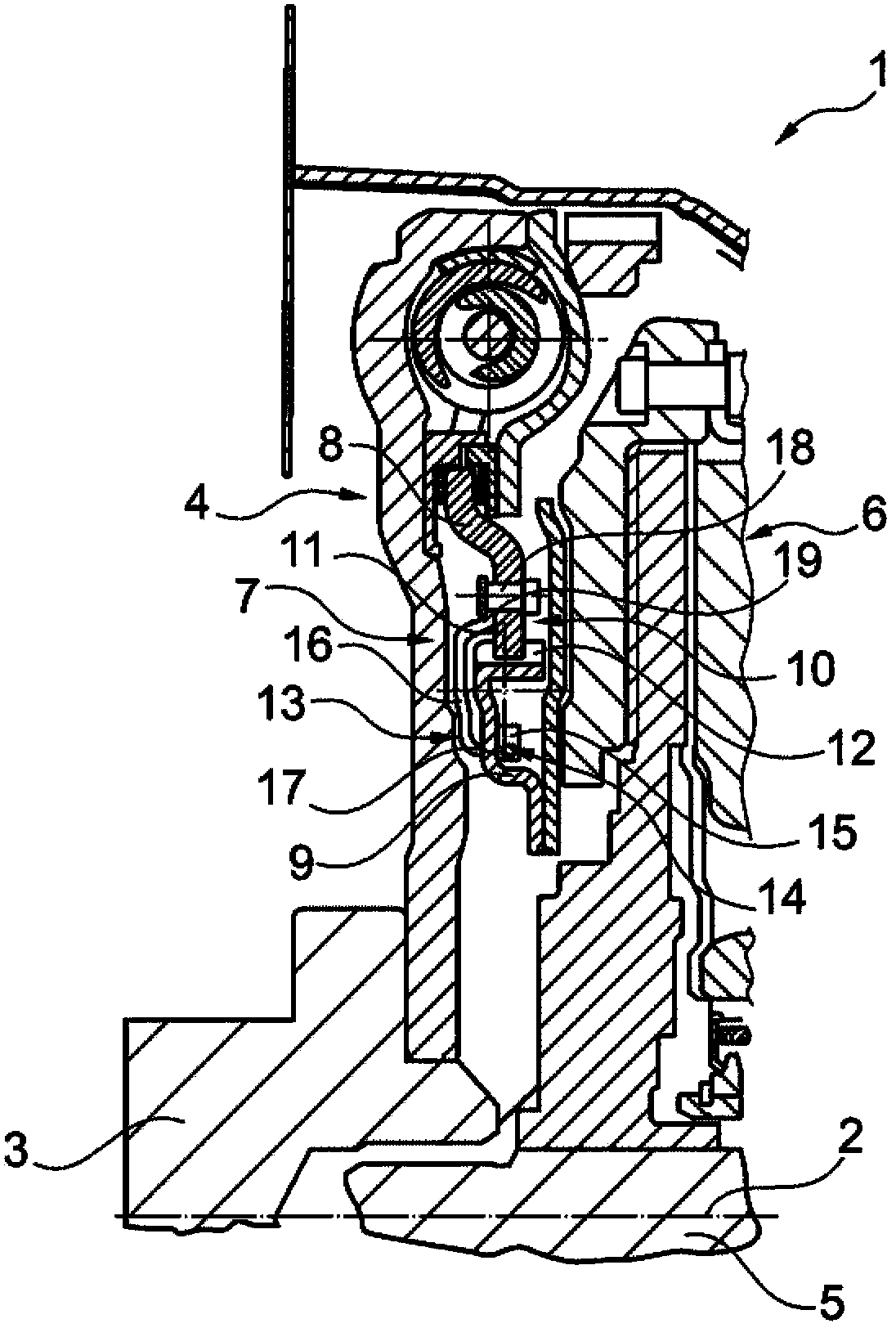

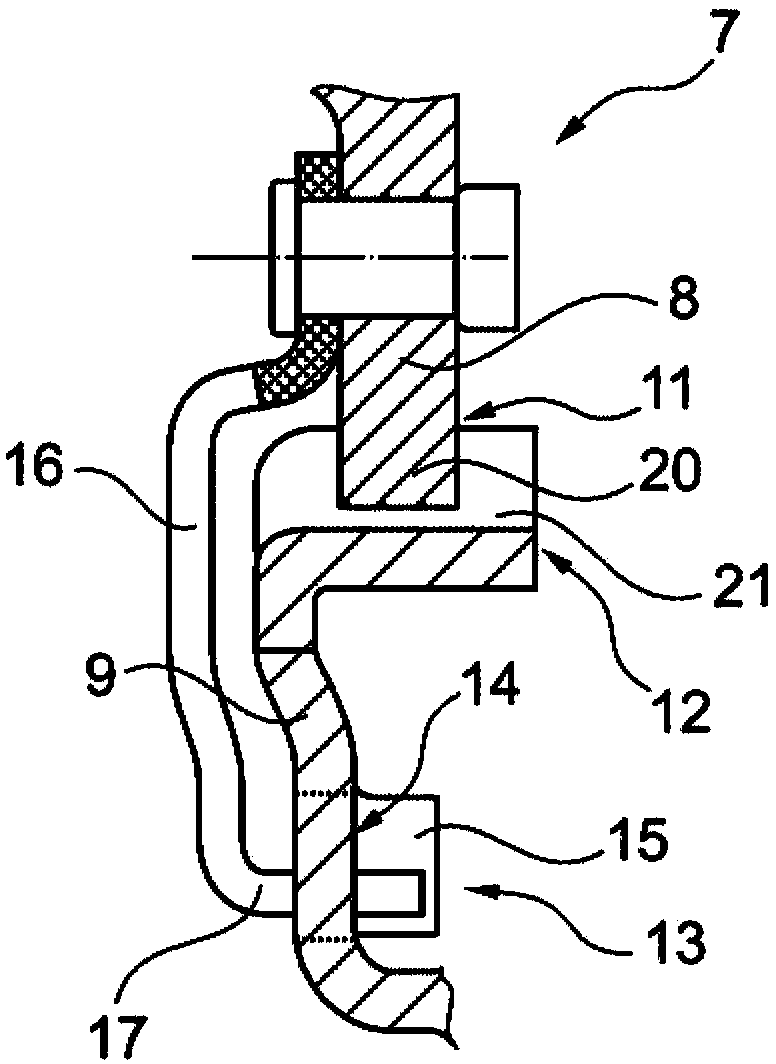

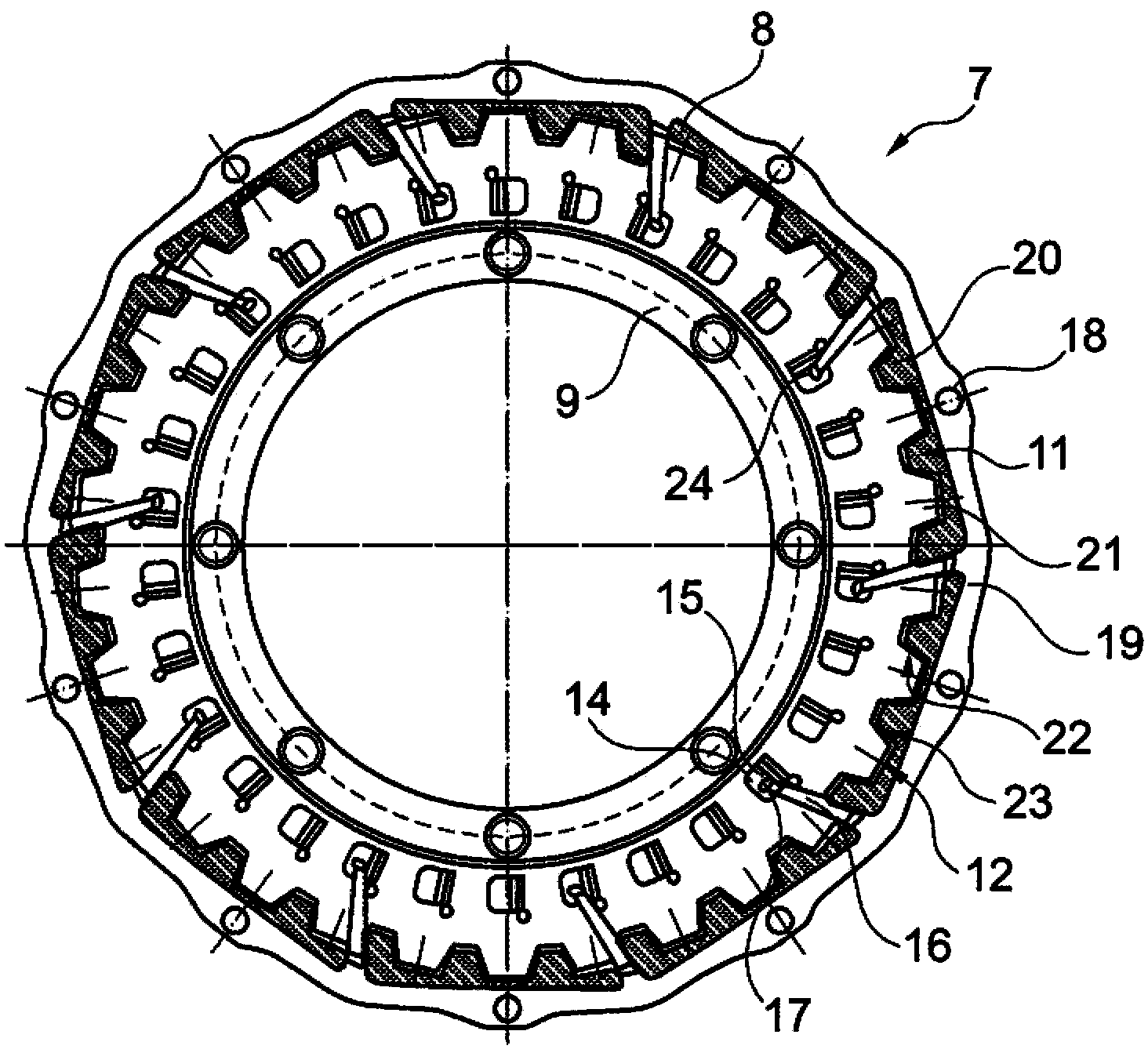

[0018] figure 1 Shown in partial section is a device 1 mounted around an axis of rotation 2 with a rotational vibration damper 4 fixedly received on the crankshaft 3 of an internal combustion engine on the drive side, such as a dual-mass flywheel, and received on the driven side by a transmission The friction clutch 6 on the input shaft 5 , shown only partially, can also be a double clutch. Before the final installation of the device 1, the rotational vibration damper 4 received on the crankshaft 3 of the drive train attached to the structural group fixed on the engine side and the friction clutch 6 received on the transmission input shaft 5 are used in the final installation by means of plug-in The plug connections 7 are connected to one another in a rotationally fixed manner. The plug connection 7 is formed with a drive-side part 8 , here the output side of the torsional vibration damper 4 , and a driven-side part 9 , here a plate connected to the input side of the frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com