High-pulse-repetition-frequency ultra-short laser pulse system

A technology of ultra-short laser and pulse system, which is applied to lasers, laser components, phonon exciters, etc., and can solve problems such as difficult mode locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing and embodiment, and present embodiment is carried out under the premise of technical scheme of the present invention, has provided detailed embodiment and specific operation process, but protection scope of the present invention is not limited to the following the described embodiment.

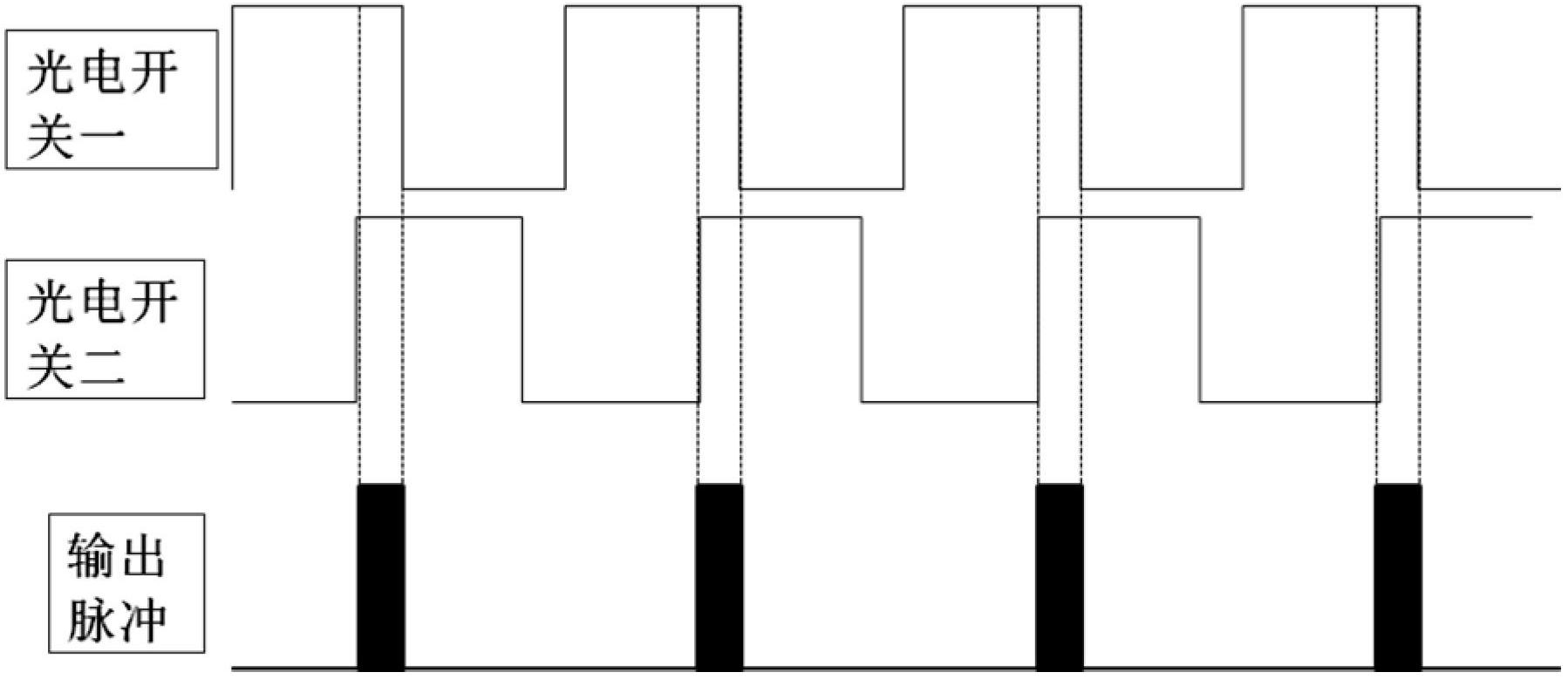

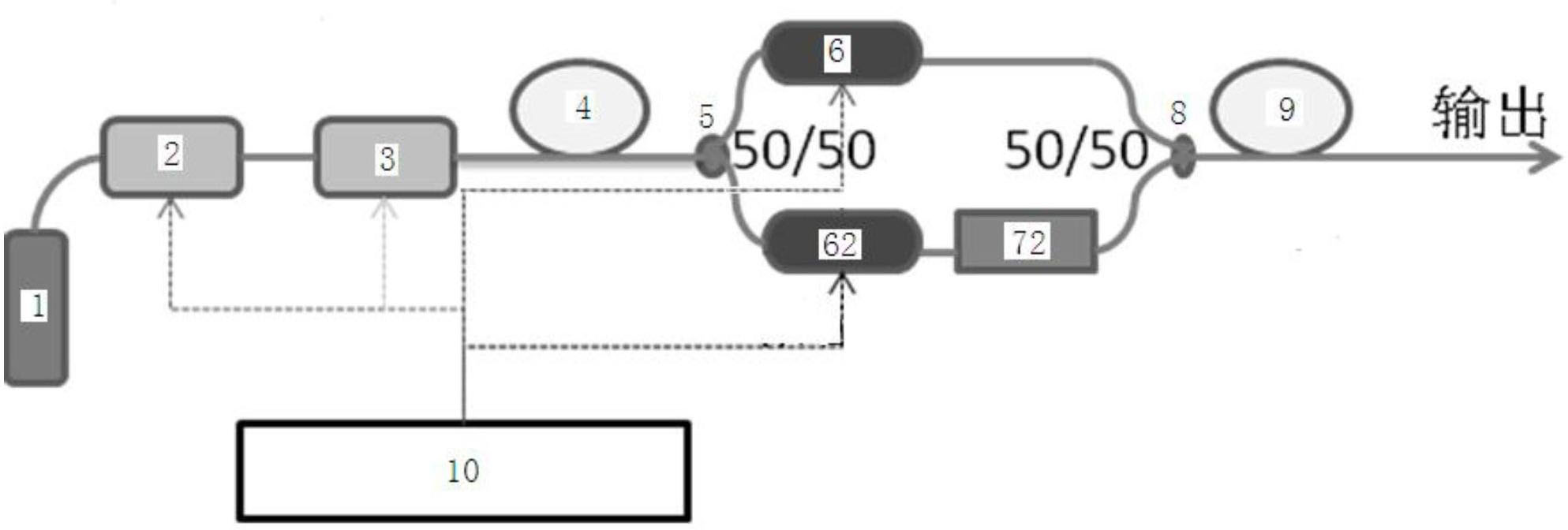

[0020] figure 1 It is a schematic diagram of the optical path of Embodiment 1 of the high repetition rate ultrashort laser pulse system of the present invention. It can be seen from the figure that the high-repetition-frequency ultrashort laser pulse system of the present invention adopts a single longitudinal mode laser 1 as a light source, and its composition also includes a first photoelectric switch 2 and a second photoelectric switch 2 sequentially arranged along the direction of the pulsed light output by the single longitudinal mode laser 1. Photoelectric switch 3, first ytterbium-doped f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extinction ratio | aaaaa | aaaaa |

| Bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com