Automatic adjusting type edge cutter for copper strip production

An automatic adjustment and trimming machine technology, applied in the direction of shearing devices, shearing machine accessories, shearing machine equipment, etc., can solve problems affecting production efficiency, inconvenient adjustment methods, operation risks, and difficulty in ensuring accuracy, etc., to achieve work High efficiency, long service life, labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

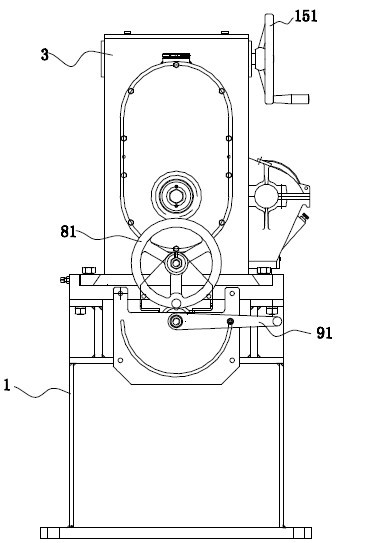

[0016] Such as figure 1 , figure 2 with image 3 As shown, the self-adjusting edge trimmer for copper strip production provided in this embodiment includes a base 1, a power motor 12, two symmetrically arranged heads 3 and corresponding cutter wheels fixed on the heads 3 group, the power motor 12 is fixed on the machine base 1, and the cutter wheel group is composed of an upper cutter wheel 52 and a lower cutter wheel 42 arranged symmetrically up and down. The transmission rod installation hole 32 and the auxiliary transmission shaft installation hole 31, the two main transmission rod installation holes 32 are equipped with main shaft sleeves 41, and bearings 7 are embedded in the port positions of the two main shaft sleeves 41, and the two main shaft sleeves 41 are located A lower cutter wheel 42 is respectively socketed on the end of the corresponding machine head 3, and is fixed by the limit wheel 6 at the same time. The transmission is connected with the main transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com