Regeneration method for activated carbon adsorbed and saturated by refractory organics

A technology of refractory organic matter and activated carbon, which is applied in the regeneration field of refractory organic matter adsorbed and saturated activated carbon, which can solve the problems of time-consuming and laborious, generation of regeneration waste liquid, etc., and achieve the effect of simple equipment, improved pore structure and adsorption performance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Static adsorption experiment

[0028] The first step: Weigh 1g of coconut shell granular activated carbon produced by Songhua Activated Carbon Company, measure 400ml of disperse dye biochemical wastewater (COD=326mg / L) and stir and absorb for half an hour, filter out the activated carbon, and measure the COD of the wastewater;

[0029] Step 2: Turn on the ultrasonic generator, connect the activated carbon obtained in the first step with the ultrasonic generator, the ultrasonic frequency is 22kHz, and the power is 30W / dm 3 ;

[0030] The 3rd step: prepare the ferrous sulfate solution that mass content is 20%, pH is adjusted to 3, pass in the gac obtained in the second step by the amount of 0.2ml ferrous sulfate / g gac;

[0031] The 4th step: prepare the hydrogen peroxide solution that mass content is 10%, according to the amount of the ferrous sulfate solution that adds in the 3rd step, pass 0.9ml hydrogen peroxide in the activated carbon that the 3rd step ...

Embodiment 2

[0041] Embodiment 2: dynamic adsorption experiment

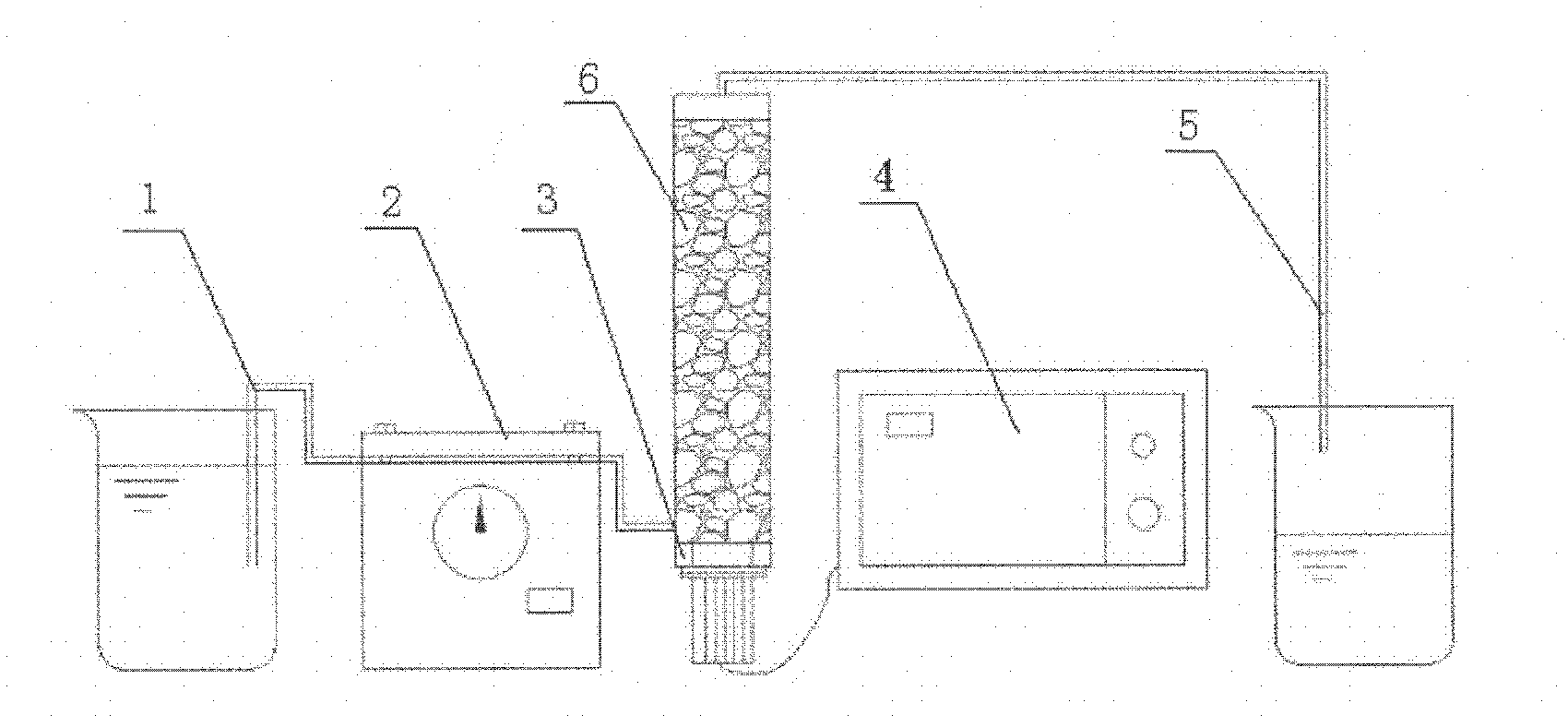

[0042] Such as figure 1 As shown, one end of the constant flow centrifugal pump 2 is connected to the water inlet pipe 1, and the other end is connected to the lower left end of the dynamic adsorption column 3, and the flow rate is set to 28m / h. The dynamic adsorption column 3 is 0.34m high and has a radius of 0.01m. The upper end of the dynamic adsorption column 3 is connected to the water outlet pipe 5, and the lower end is connected to the ultrasonic generator 4, and the adjusted power is 300W.

[0043]The first step: take 50g of 20 mesh coconut shell granular activated carbon 6 from Songhua Activated Carbon Company, measure 2000ml of disperse dye biochemical wastewater (COD=510mg / L) and stir and adsorb for half an hour, then filter the activated carbon 6;

[0044] The second step: configure a ferrous sulfate solution with a mass content of 30%, and adjust the pH value to 2;

[0045] The third step: take 40g of the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com